Antistatic optical substrate preparation method

An optical substrate, anti-static technology, applied in the direction of optics, optical components, ion implantation plating, etc., can solve the problem of easy to absorb dust and achieve the effect of not easy to absorb dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

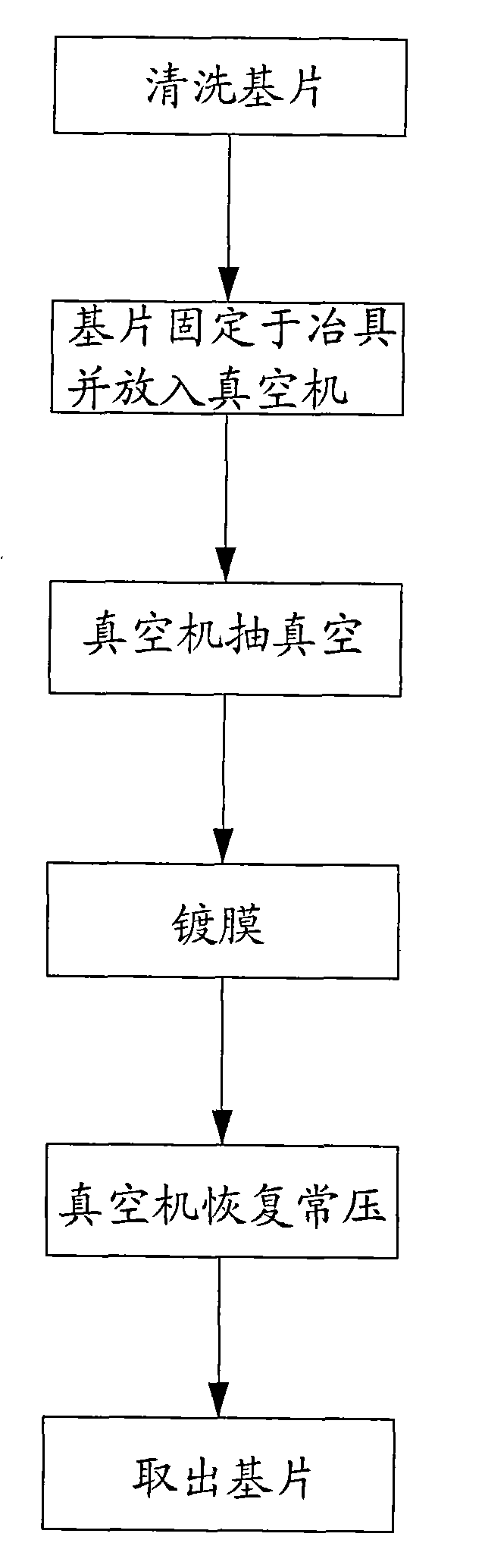

[0017] Example: a structure such as figure 1 As shown, an antistatic optical substrate preparation method, the process is as follows: clean the substrate - put the substrate on the jig (frame for fixing the substrate) - put the jig into the vacuum machine - -Evacuate the vacuum machine to a certain condition--coating process (the specific process is as follows)--the machine is deflated--take out the substrate.

[0018] Coating process: After the substrate is cleaned, it is placed in a vacuum and pumped to 1x10 -5 Torr to 5x10 -5 In Torr’s high-vacuum machine, alternating high-refractive index film layers and low-refractive index coating layers are sequentially deposited on the substrate, and then the super waterproof coating material WR5 is evaporated and deposited on the film layer in a molecular state to form a new A film layer, and the thickness of the WR5 new film layer is 120-220nm, take out the substrate to form an antistatic optical substrate.

[0019] The at least o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com