Device for inserting and placing shank for precision cutter diamond coating

A diamond coating, precision tool technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problems of inconvenient use, low processing efficiency, etc., to reduce costs, improve production and processing efficiency, The effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

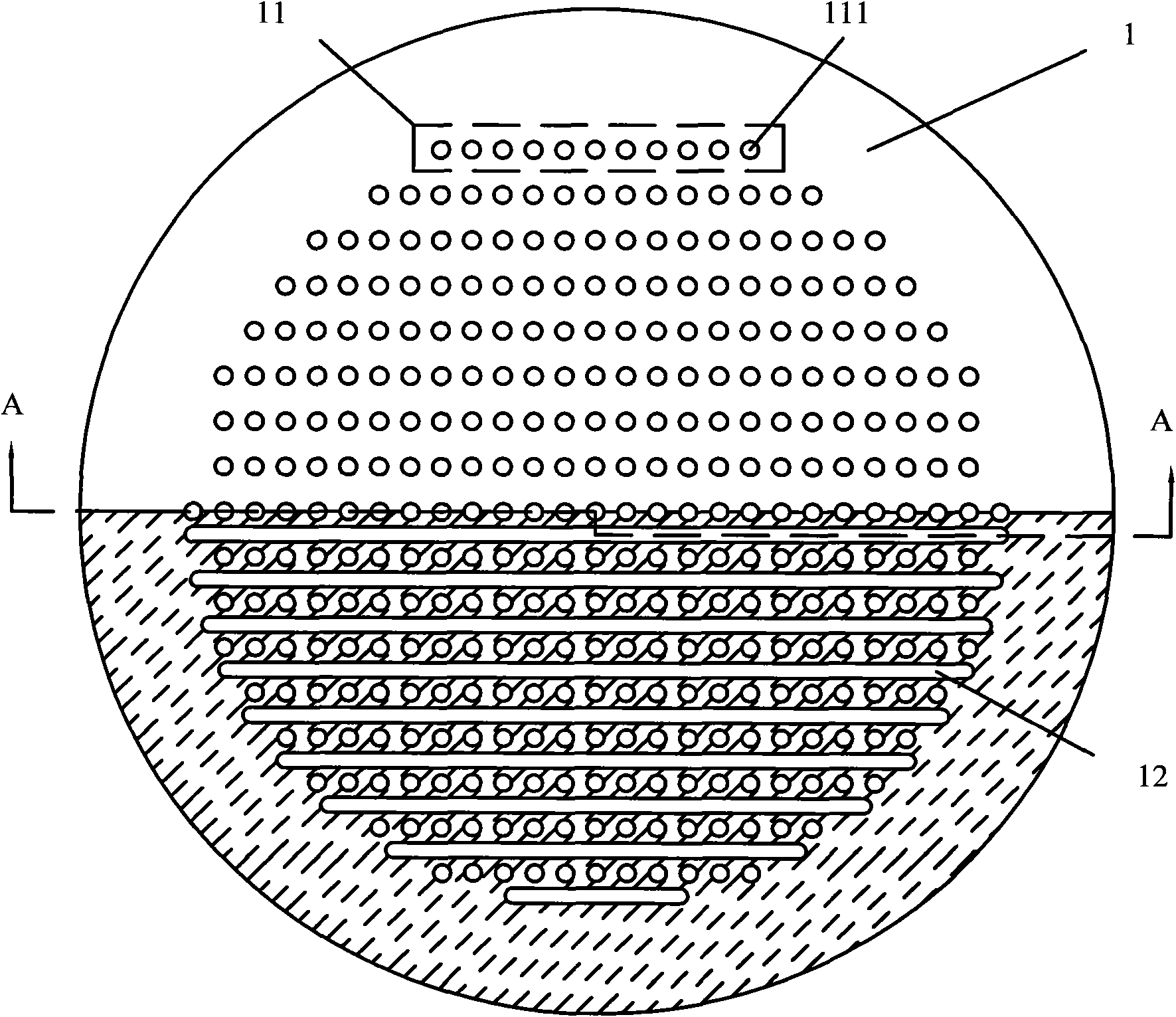

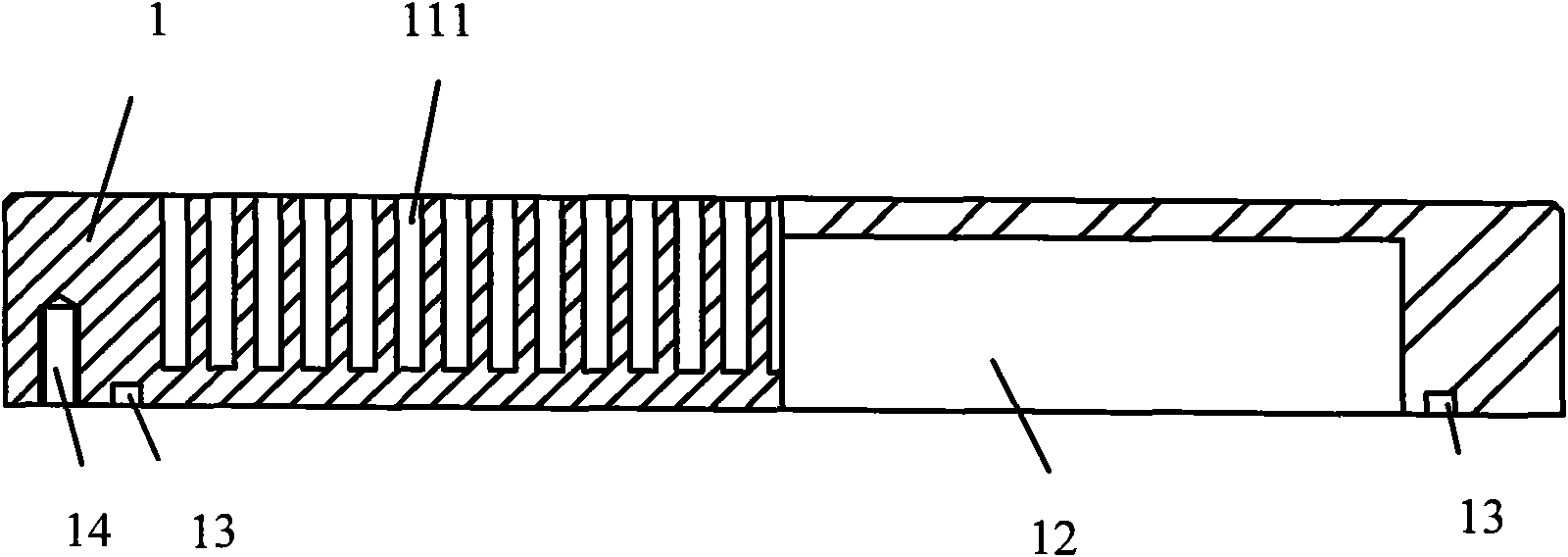

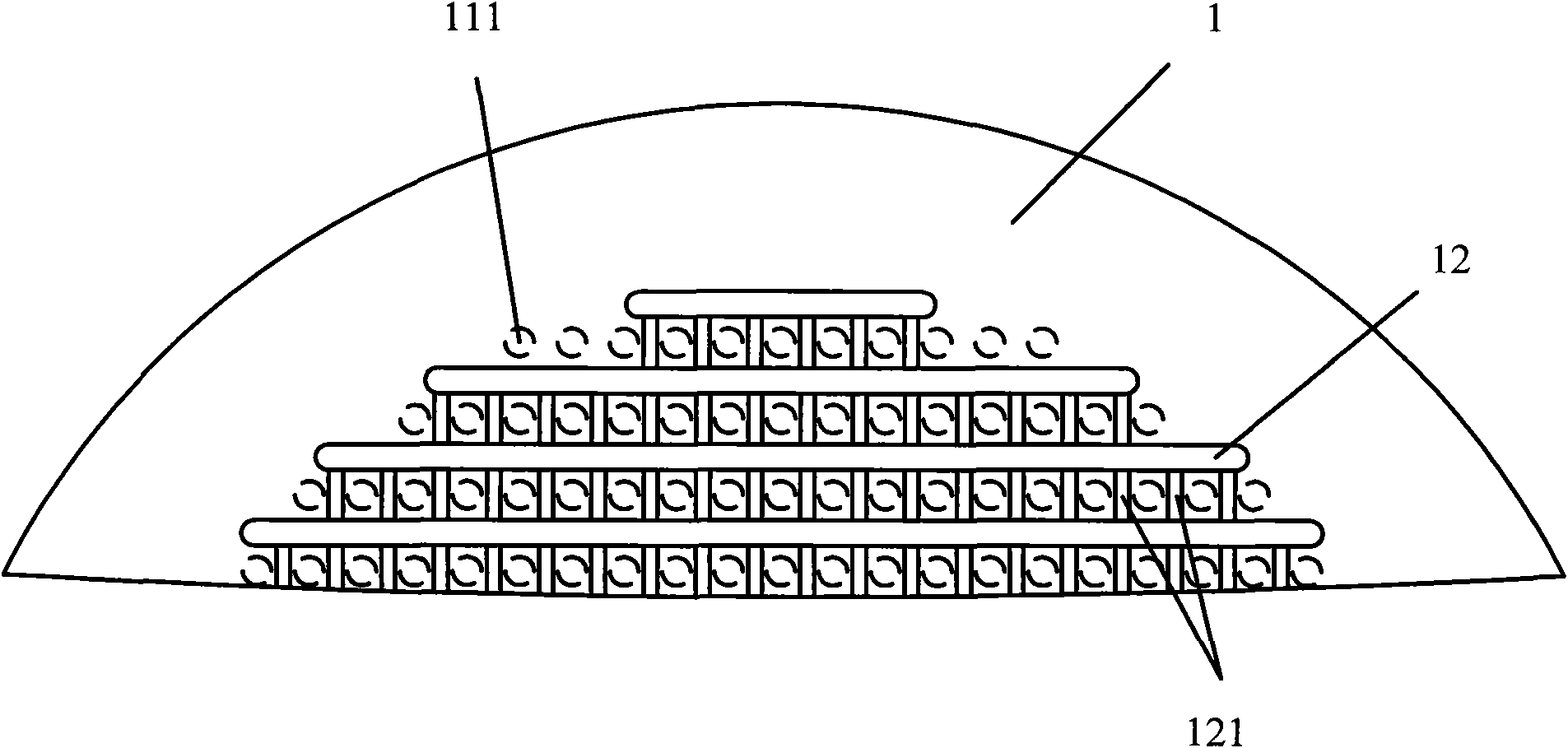

[0029] On the basis of not changing the shape and size of the shank of the precision tool, the present invention only performs structural modification and design on the inserting device of the precision tool during the diamond coating process. The knife handle inserting device 1 for precision tool diamond coating described in the present invention is cake-shaped, adopts heat-resistant material to make, and it comprises the knife handle inserting part that is arranged on the upper surface of knife handle inserting device 1, and setting The cooling part on the lower surface; the knife handle inserting part includes at least two groups of knife handle insertion holes for inserting the knife handle and requiring high precision of the inner wall.

[0030] Since the diamond coating processing of precision cutting tools in the prior art is a single c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com