Spraying device for salt spray test chamber

A spray device and salt spray test technology, applied in spray devices, measuring devices, instruments, etc., can solve problems such as inability to meet spray power, inability to apply, and spray discontinuity in a single area, and achieve uniform salt spray deposition and save money. Cleaning time, improved reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

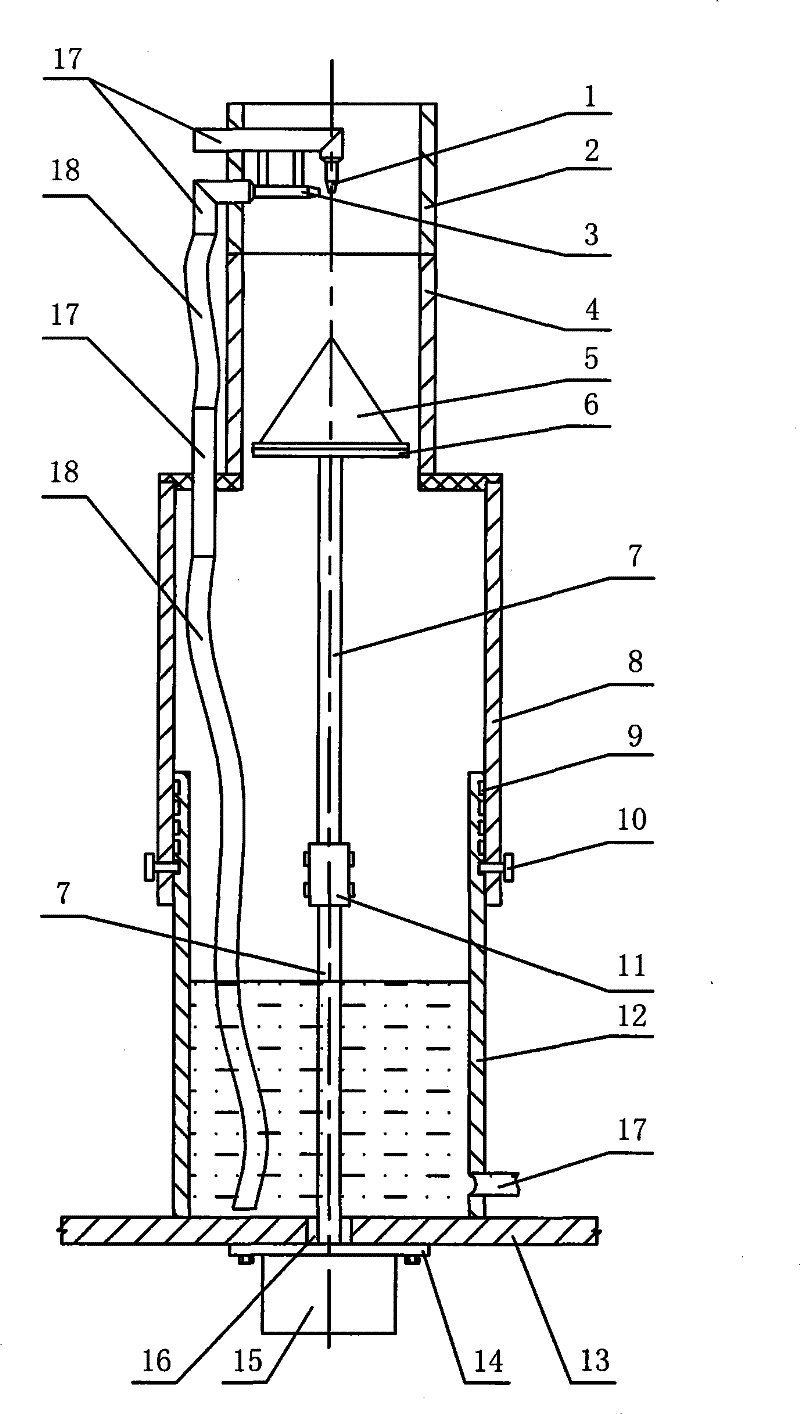

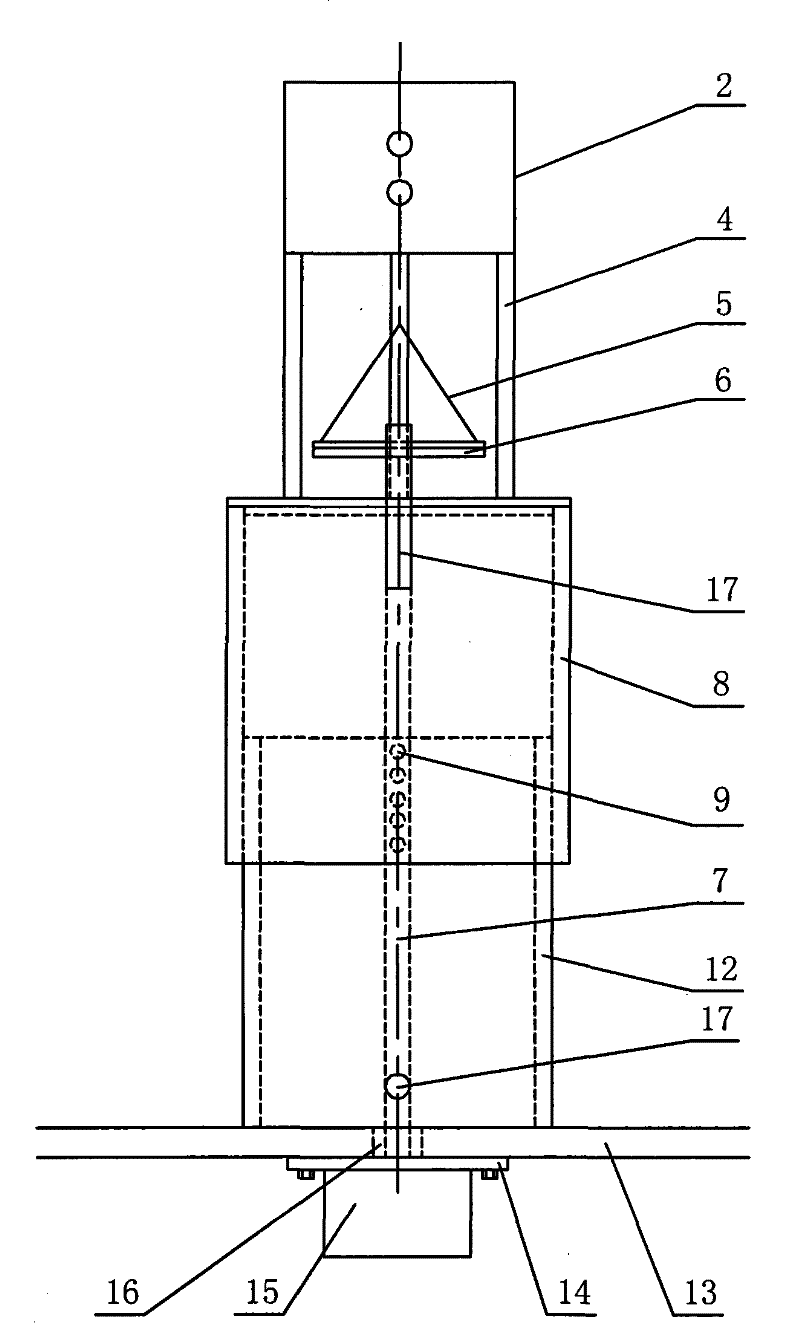

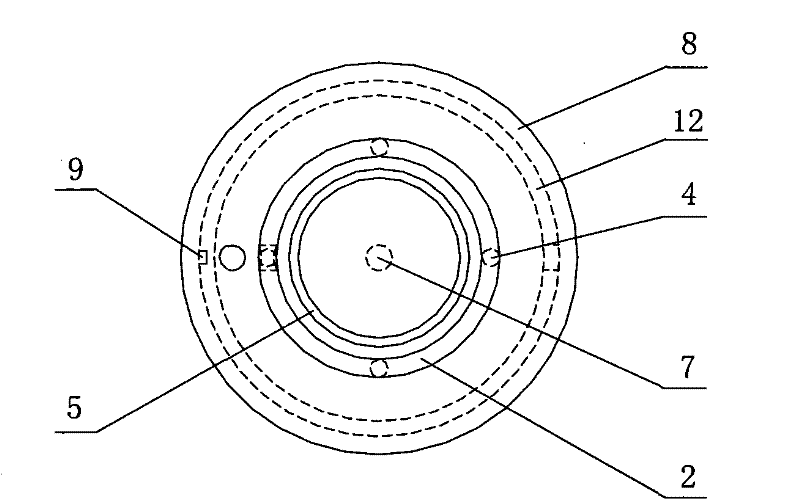

[0021] A spray device for a salt spray test chamber, comprising a hollow cylindrical tower body, a conical tower cap 5, a gas nozzle 1, a gas pipeline, a liquid nozzle 3, a liquid pipeline and a transmission device 15; the tower body is vertically fixed on the salt On the inner wall of the bottom of the mist box body 13, the tower body is divided into three sections from top to bottom, followed by tower body one 2, tower body two 8 and tower body three 12; tower body one 2 and tower body two 8 pass through four The root column 4 is supported, and the column 4 is evenly distributed along the outer circumference of the bottom of the tower body one 2, and the diameter of the column 4 is the same as the wall thickness of the tower body one 2; the tower body two 8 and the tower body three 12 are connected by fastening bolts 10, A group of mutually symmetrical positioning devices 9 are provided at the position where the outer wall of the tower body 3 12 is connected to the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com