Screw motor

A screw and shell technology, applied in the field of screw motors, can solve the problems of energy conversion efficiency and low acceleration, and achieve the effect of high acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

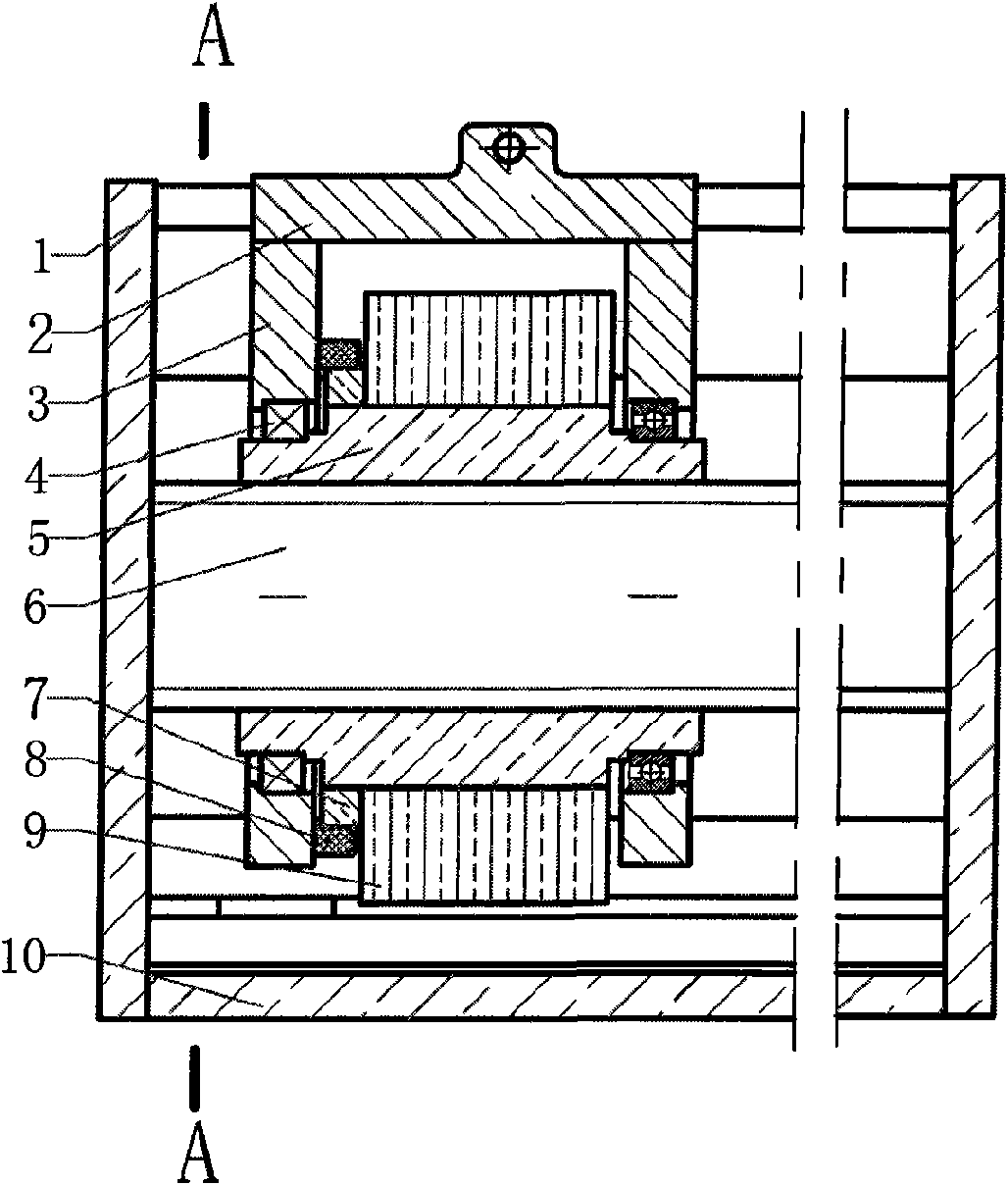

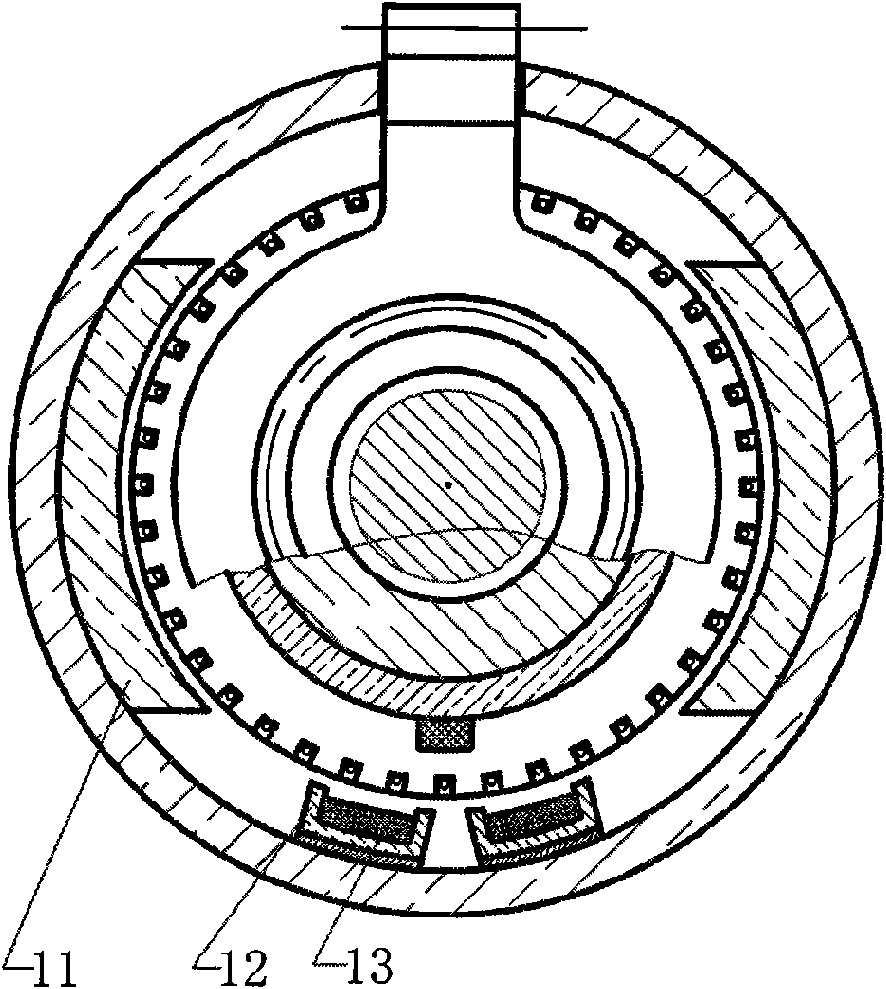

[0008] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is described further.

[0009] In order to make the motor have higher efficiency, the stator adopts permanent magnet poles, and the rotor armature adopts a slide rail power supply method similar to that of an electric locomotive.

[0010] In the figure, the stator poles (11) are fixed on the housing (10). Armature (9) and commutator (7) are fixed on the nut (5) to form the rotor. The commutator brush (8) and the power supply brush (13) are both installed on the shift fork, and are responsible for supplying power to the armature (9). The power supply slide rail (12) is fixed on the housing. The end cover (1) is fixed on the housing (10), and the screw shaft (6) is fixed on the end cover (1). The shift fork (3) is fixed together with the shift fork beam (2). The shift fork beam (2) is located in the groove of the housing and can slide in the groove. It is responsible for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com