Tobacco leaf vacuum charging system and method

A technology of feeding system and feeding method, which is applied to tobacco, tobacco preparation, application, etc., can solve the problems of non-conformity to vacuum absorption, long residence time, vacuum degree damage, etc., so as to enhance the ability of absorbing material liquid, as well as uniformity and simplification. Equipment structure, the effect of ensuring work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

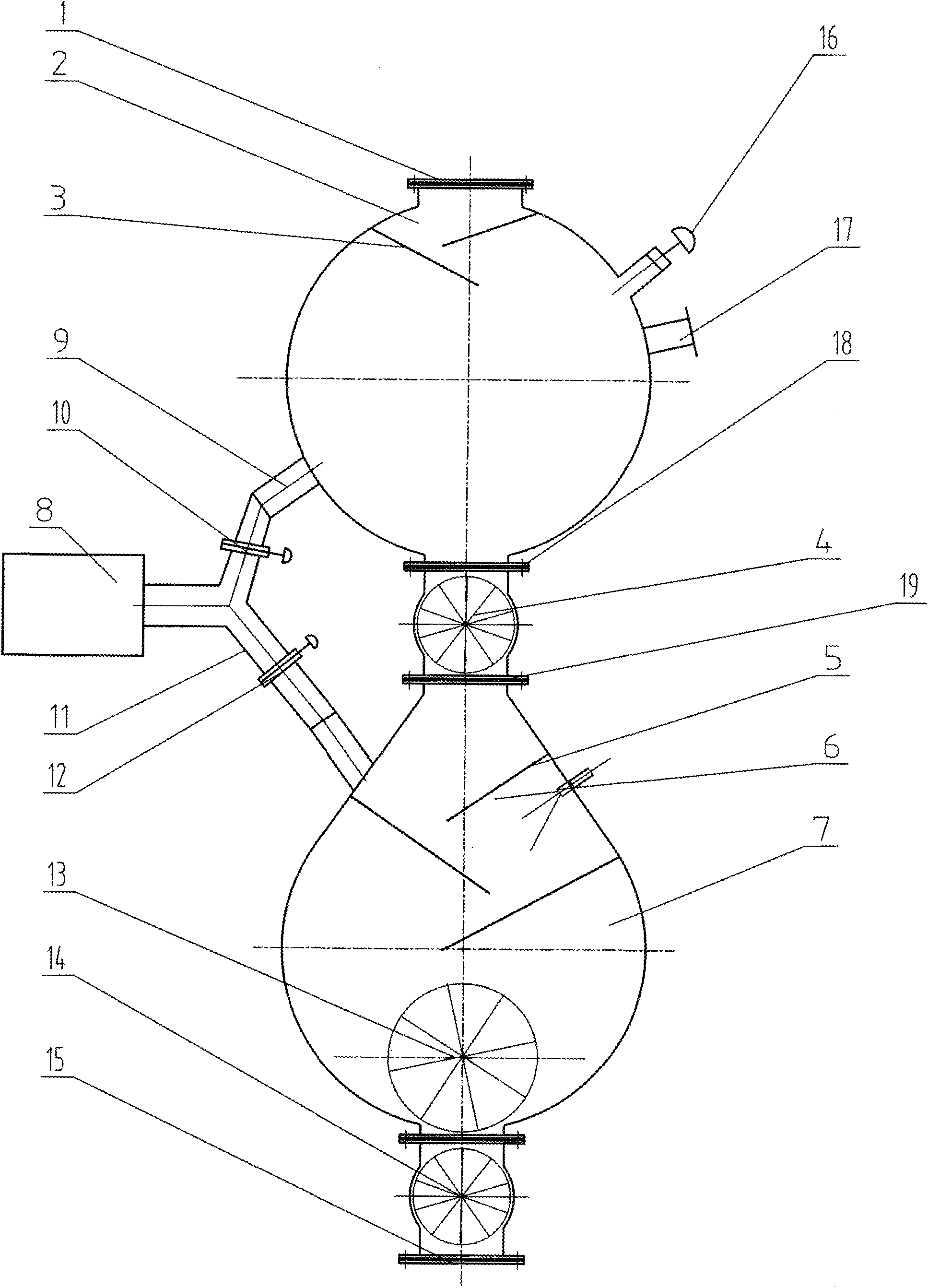

[0014] As shown in the figure, the present invention comprises the connected first negative pressure container 2 and the second negative pressure container 7, and the vacuum unit 8 communicates with the first negative pressure container 2 and the second negative pressure container 2 through the first vacuum pipeline 9 and the second vacuum pipeline 11 respectively. Negative pressure container 7 is connected; On the first negative pressure container 2, be provided with the first feed door 1, the first discharge door 18, vacuum breaking valve 16 and safety valve 17, be provided with the first negative pressure container 7 Two feed gates 19, the second discharge gate 15 and the feeding nozzle 6 leading into the second negative pressure container, the first feeder 4 is sealingly connected between the first discharge gate 18 and the second feed gate 19 The lower end of the second negative pressure container 7 is sealed with a second feeder 14; the first vacuum pipeline 9 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com