Two-time fermentation method for Liupao tea

A technology of secondary fermentation and Liubao tea, which is applied in the direction of tea treatment before extraction, can solve the problems of affecting the quality of tea, uneven and insufficient fermentation, and long fermentation period, so as to shorten the fermentation time, shorten the fermentation time, Uniform and full effect of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The secondary fermentation method of Liubao tea includes the following steps in sequence: picking tea, killing greens, rolling, fermenting, drying, sieving, blending, stacking, drying, steaming tea, extruding, secondary fermentation, and aging;

[0024] Described fermentation comprises the following steps:

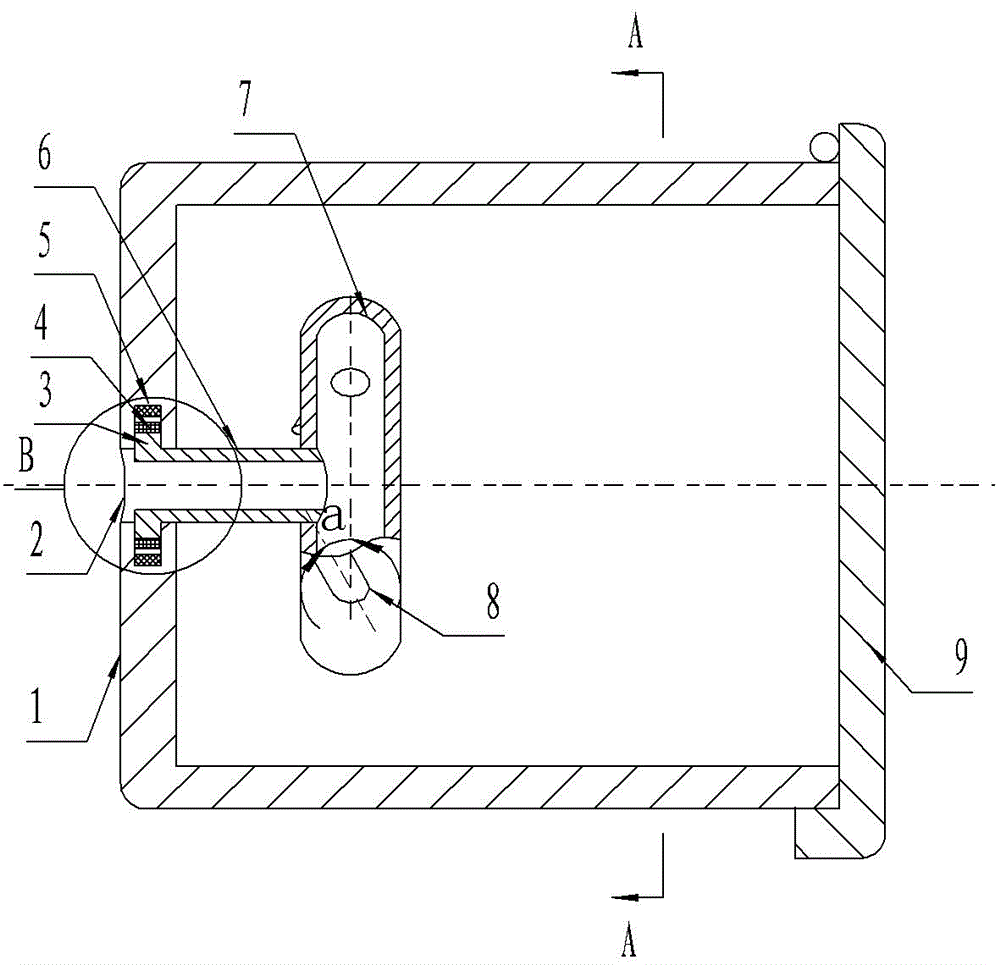

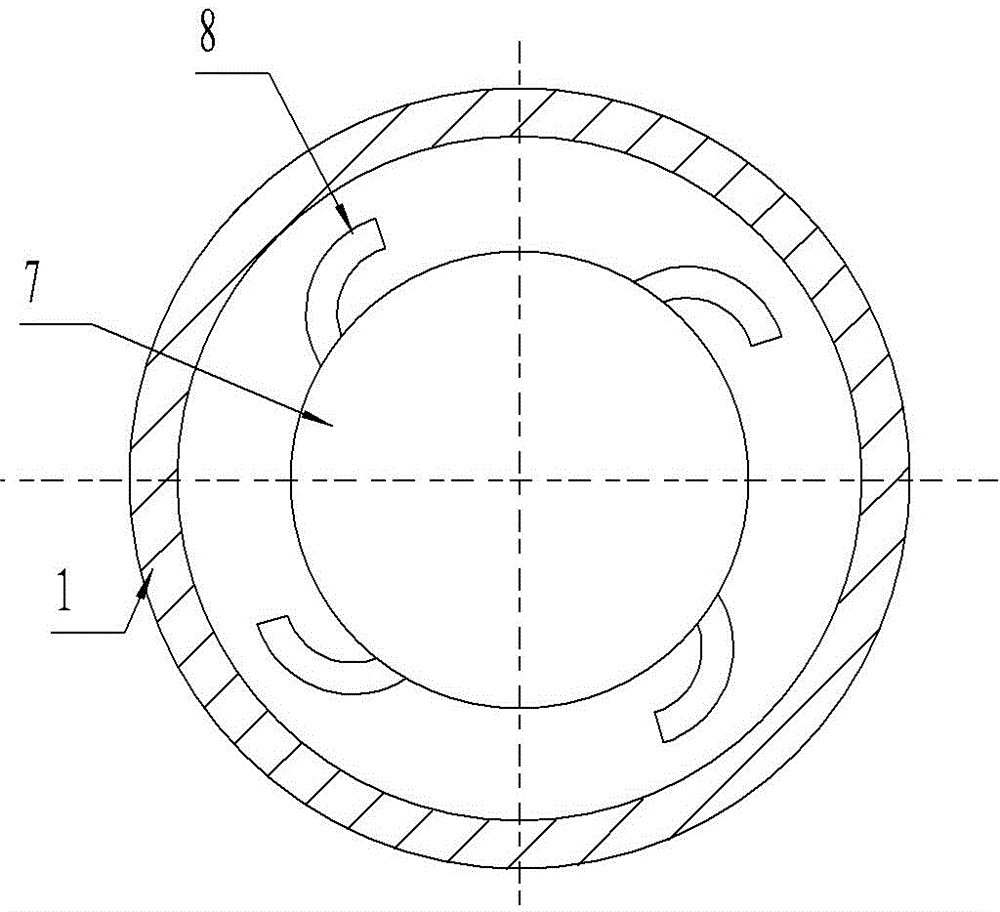

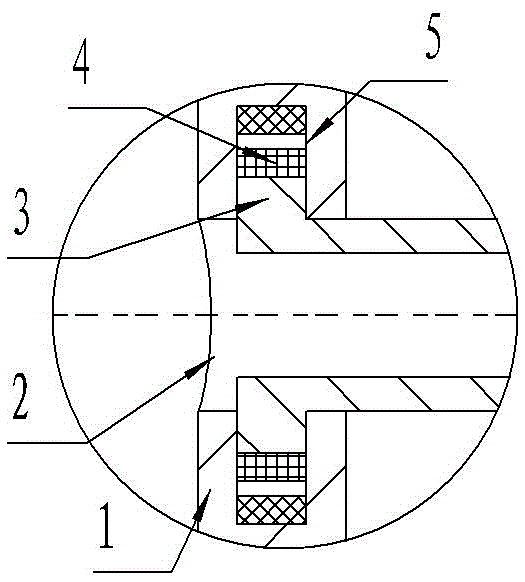

[0025] A. Put the tea leaves into the tea tube 1 of the tea fermentation device, close the cover 9, connect the fermented liquid tube and the compressed air tube through the three-way joint at the opening of the tea tube 1; Inject compressed air and fermented liquid, the rotating speed of water tray 7 is 2800 rev / s, disconnect electromagnet 4 power supply after 10 minutes, stop spraying compressed air and fermented liquid, after 5 hours, electromagnet 4 is energized and compressed air is connected for 10 minutes, The compressed air stops, and the rotating speed of the water tray 7 is connected to the fermentation broth for 10 minutes at 3000 rpm, and then stopped fo...

Embodiment 2

[0030] The secondary fermentation method of the present Liubao tea comprises the following steps in sequence: tea picking, degreening, rolling, stacking, drying, sieving, blending, stacking, drying, tea steaming, extrusion, cooling and aging.

[0031] Described fermentation comprises the following steps:

[0032] A. Put the tea leaves into the tea tube of the tea fermentation device, close the cover, connect the fermented liquid tube and the compressed air tube through the three-way joint at the opening of the tea tube; A. B, connect the electromagnet to the power supply, and connect the compressed air and Fermentation liquid, the speed of the water pan is 2700 rpm. After 10 minutes, disconnect the electromagnet power supply, stop spraying compressed air and fermentation liquid, and after 5 hours, the electromagnet is energized and the compressed air is connected for 10 minutes. The compressed air stops and the water pan rotates. Insert the fermentation broth at 2700 rpm for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com