Air cushion suspension type conveyor

A conveying device and suspension technology, which is applied in the field of air-cushion suspended conveying devices, can solve problems such as inability to control in real time, easily damaged rubber aprons, and slow generation of air cushions, so as to improve safety, eliminate friction, and carry large conveying capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

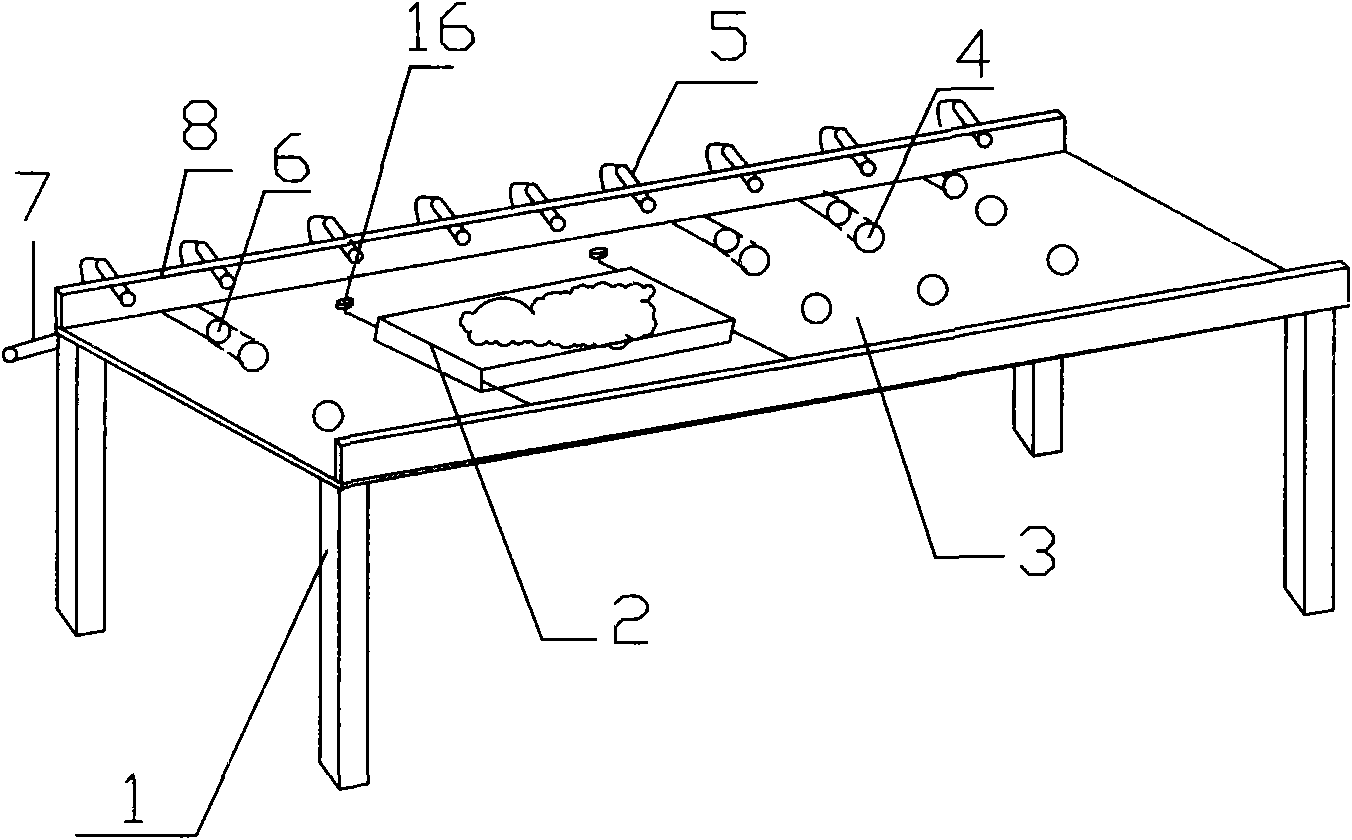

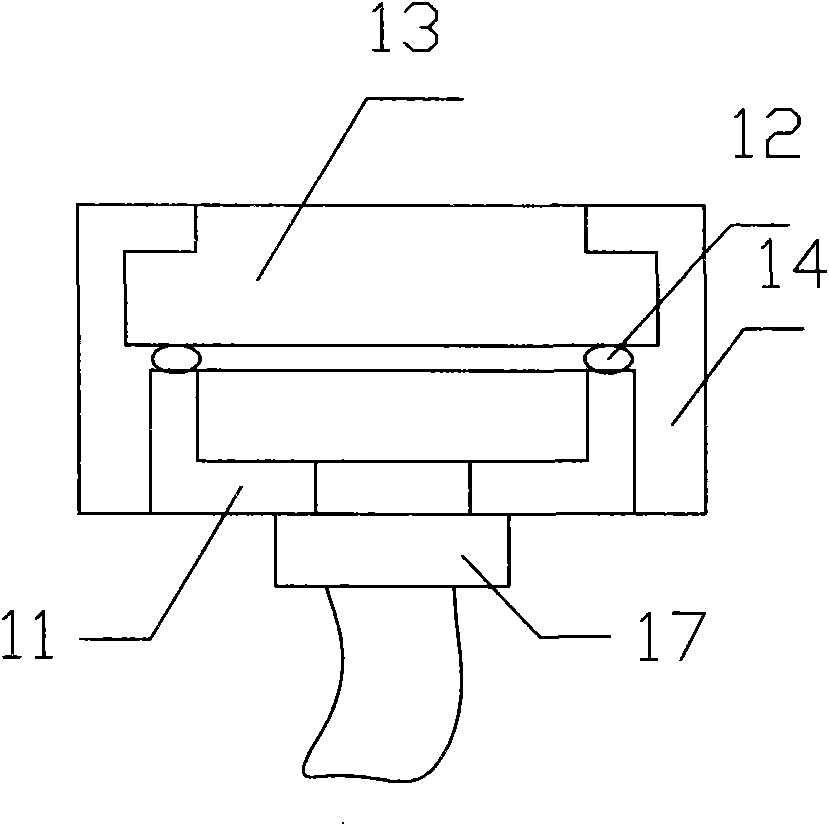

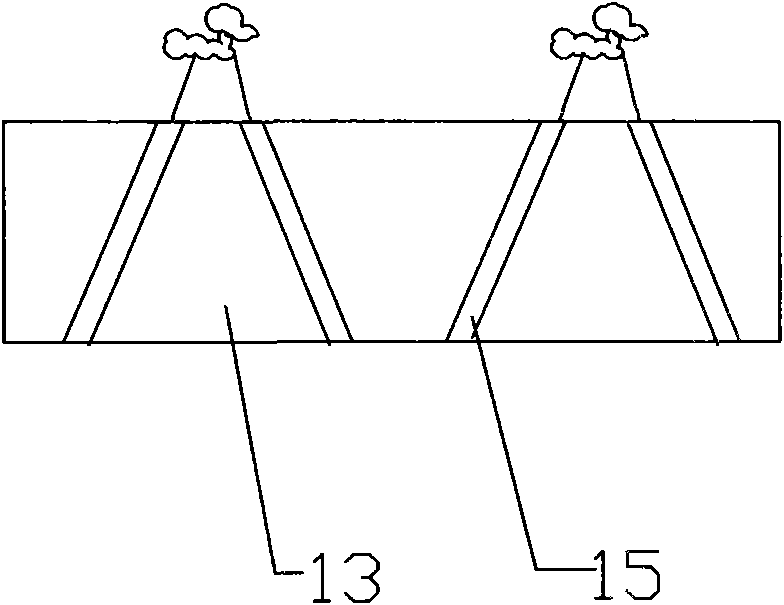

[0026] Below in conjunction with accompanying drawing, the utility model is further described: figure 1 , In 2, the air cushion suspension conveying device includes a frame 1, an air supply device 9, a flat conveyor 2, an air pipeline 7, a controller 10, a plurality of control valves 6, and the intake end of the control valve 6 passes through The air pipeline 2 communicates with the air supply device 9, and the frame 1 is provided with a working surface 3 and a channel sidewall 8. It is characterized in that: a plurality of air cushion generating devices 4 are arranged on the working surface 3, and the air cushion generating devices 4. It is composed of an air inlet nozzle 17, a machine base 14, and a labyrinth seat body 11, a sealing ring 12, and a plate 13 arranged in the machine base 14. The plate 13 is fitted with the stopper at the upper end of the inner cavity of the machine base 14, and the labyrinth seat The body 11 is threadedly connected with the lower part of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com