High-rise building construction assembled overhanging safe guarding shed and construction method thereof

A technology for safety protection and high-rise buildings, which is applied in the direction of construction, building structure, and building material processing, and can solve problems such as the limitation of cantilever length and coverage area, the inability of all materials to be reused, and the high risk of installation and disassembly. , to achieve the effects of simple method, convenient installation and removal, and improved bearing capacity and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

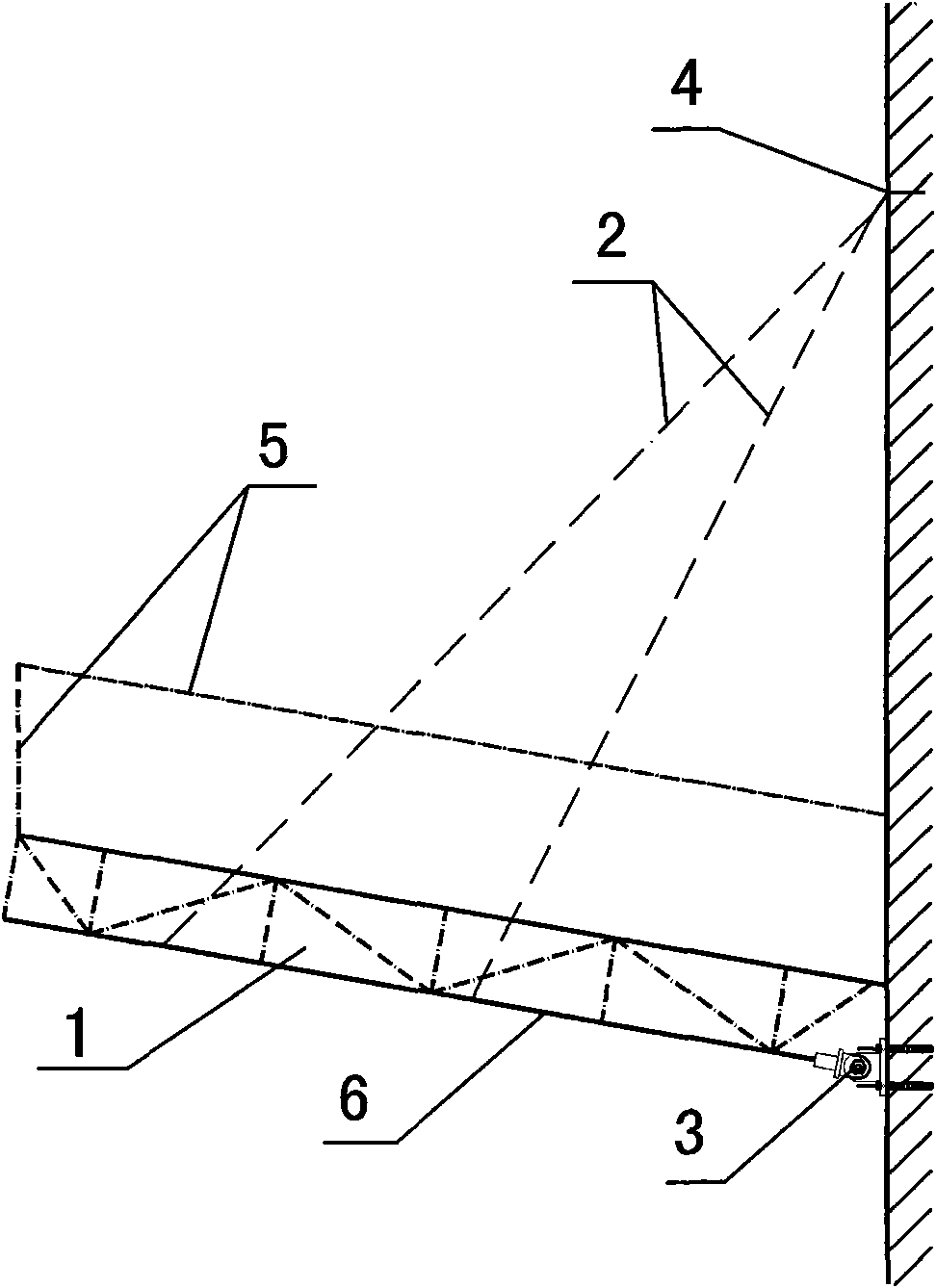

[0030] The prefabricated cantilever safety shed for high-rise building construction is composed of a cantilever main beam 6, a horizontal cross bar, a protective railing 5, a force-bearing joint seat 3, an anti-tension anchor seat 4, and an anti-tension steel wire rope 2. For the cantilevered girders, horizontal bars and protective railings of the double-layer protective shed 1, scaffolding steel pipes of Φ48×3.5 are used. The cantilevered girder, the horizontal cross bar and the protective railing are connected to form a double-layer protective shed 1 . Two anti-pull points are set on the cantilever main beam, and the two anti-pull points divide the cantilever main beam from one end of the welding movable plug-in to the other end into L 1 , L 2 , L 3 Three paragraphs, L 1 : L 2 : L 3 =1:0.8:0.41.

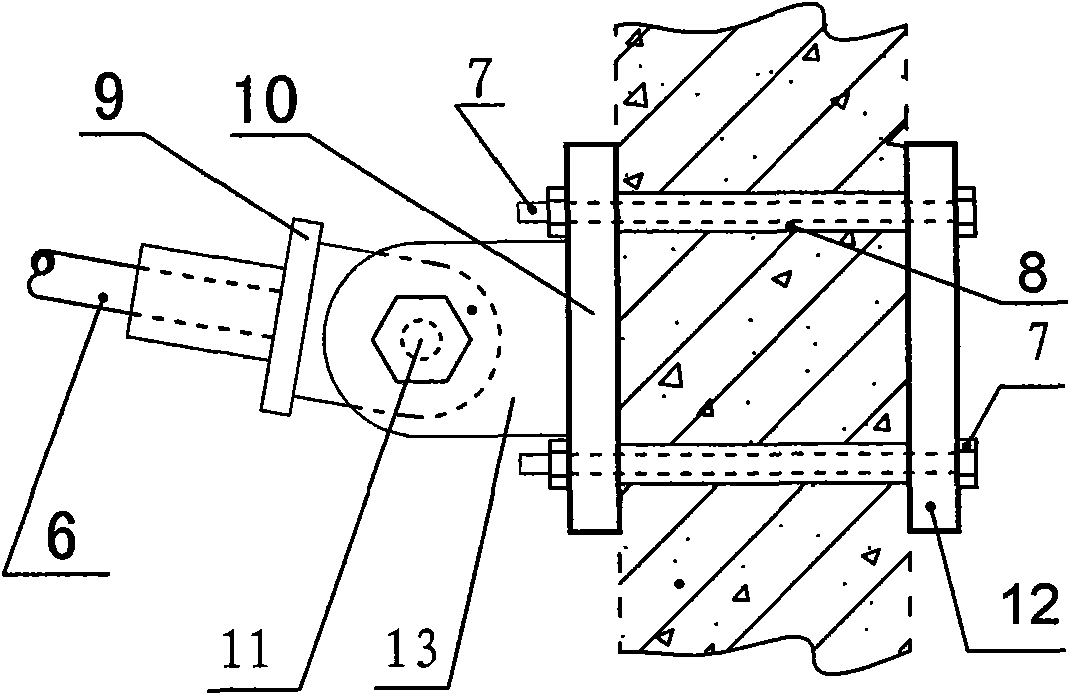

[0031] The stressed hinge seat is composed of hinge components, bolts and steel plates, and the hinge components are fixed on the main structure of the building through screw...

Embodiment 2

[0034] The construction method of building a prefabricated cantilever safety shed for high-rise building construction:

[0035] (1) Prepare the rods and stress hinge seats 3, anti-tension anchor seats 4, and anti-tension steel wire ropes 2 for the construction of high-rise building construction assembly-type cantilevered safety shelters, using Φ48×3.5 scaffolding steel pipes as the main cantilever The bar material that beam 6, horizontal bar, protective railing 5 are useful, all brush two~three antirust paints after derusting the assembled hinge assembly of stressed joint seat.

[0036] (2) In the main structure of the building, the PVC casing 8 of the stressed hinge seat and the tie round steel of the anti-tension anchor seat are pre-embedded. The PVC casing and the tie round steel are on the same vertical plane, and the tie circle The distance between the top and bottom of the steel and PVC casing is 5-6m, and the distance between the levels is less than 3m.

[0037](3) On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com