Manufacturing method of 2*2 single-side double-fin linear array based on square wave guide

A square waveguide and fin line technology, applied in the field of production of 2×2 single-sided double-fin line array, can solve the problems of unintuitive design process, complex mathematical operation, long design cycle, etc. The effect of cycle shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

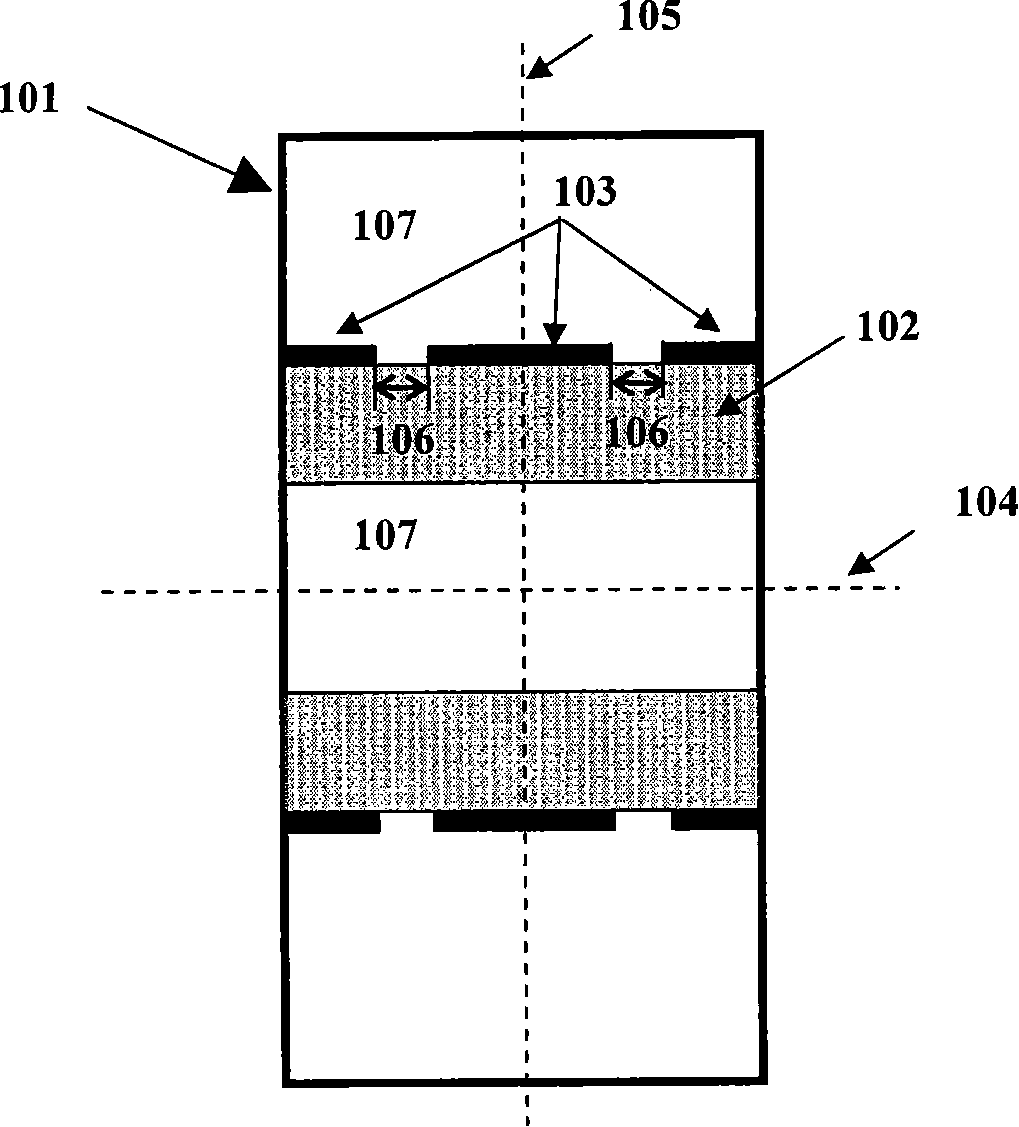

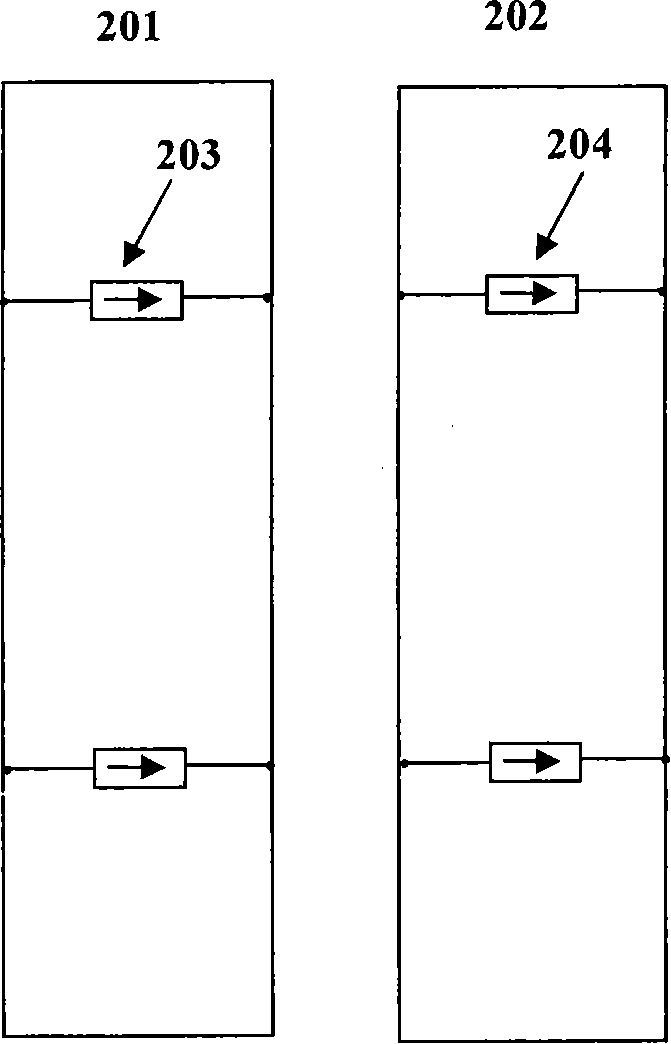

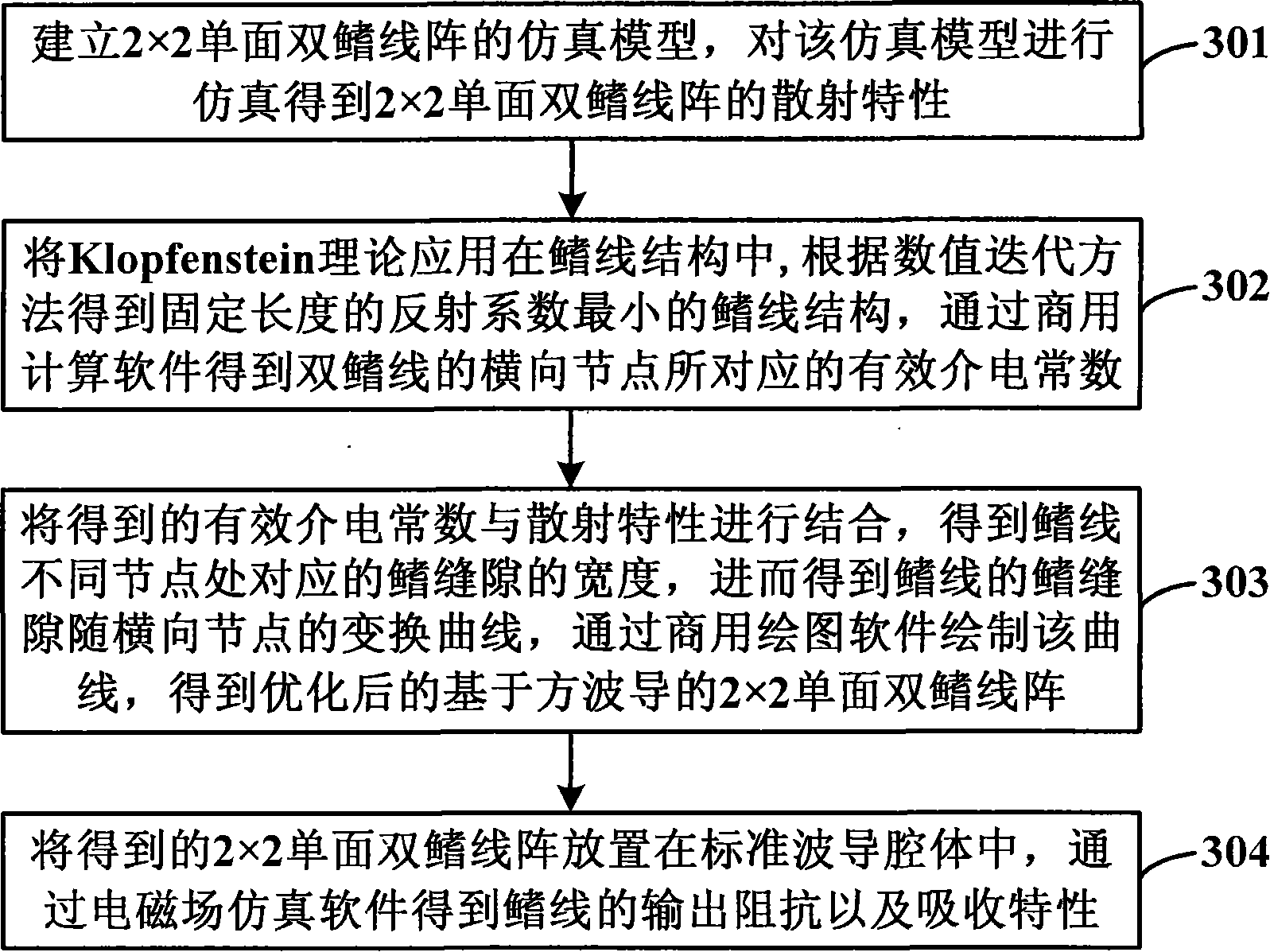

[0044] The present invention uses commercial electromagnetic field simulation software to obtain the effective dielectric propagation constants corresponding to the different slit widths of the two layers of double-fin lines in the square waveguide, and makes the simulation data into a table for easy reference, and then uses Klopfenstein theory to optimize the double-fin lines, through a cycle The iterative numerical calculation obtains the effective dielectric propagation constant corresponding to different lateral nodes of the double-fin line in the commercial calculation software. Combined with the numerical table drawn by simulation, the gap corresponding to the different lateral nodes of the double-fin line can be obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com