Refractory system for bushing assembly

A technology for bushings and components, applied in manufacturing tools, glass manufacturing equipment, etc., can solve the problems of increasing downtime of fiber forming equipment, damage to bushings, and easy rupture of thermal insulation materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] As will be readily appreciated by those skilled in the art, the description herein generally includes a schematic illustration of one suitable manufacturing method for producing glass or mineral fibers.

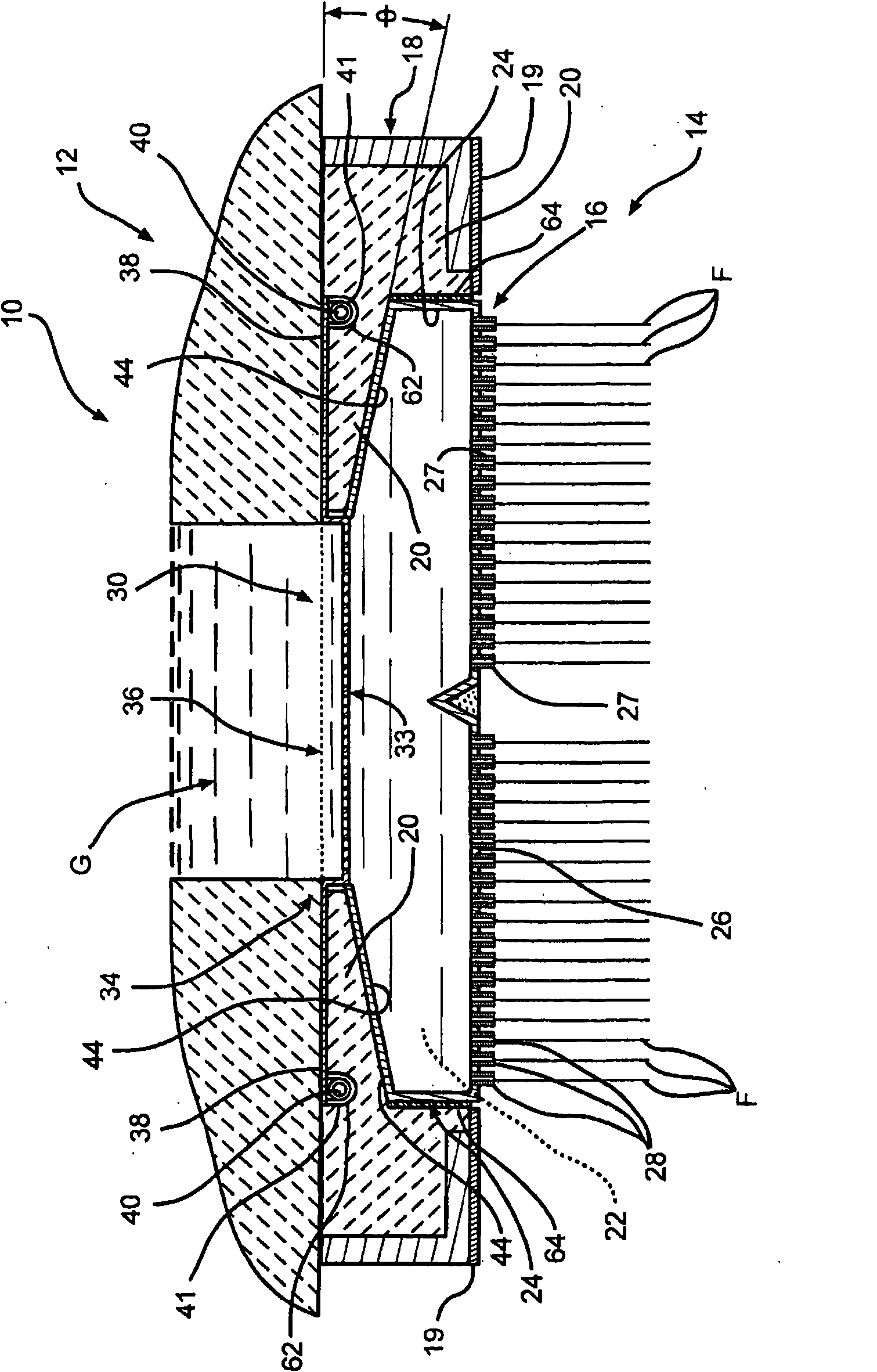

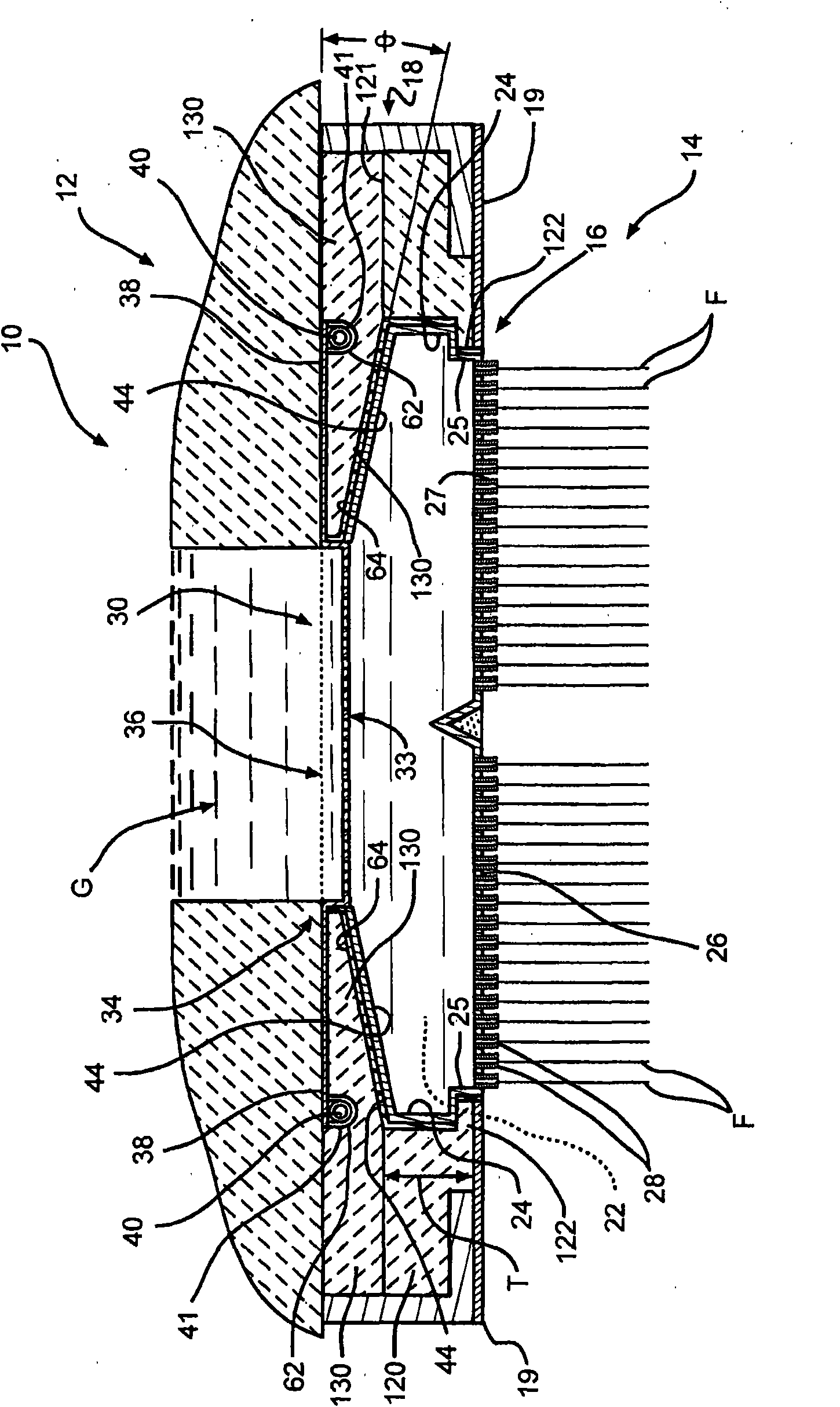

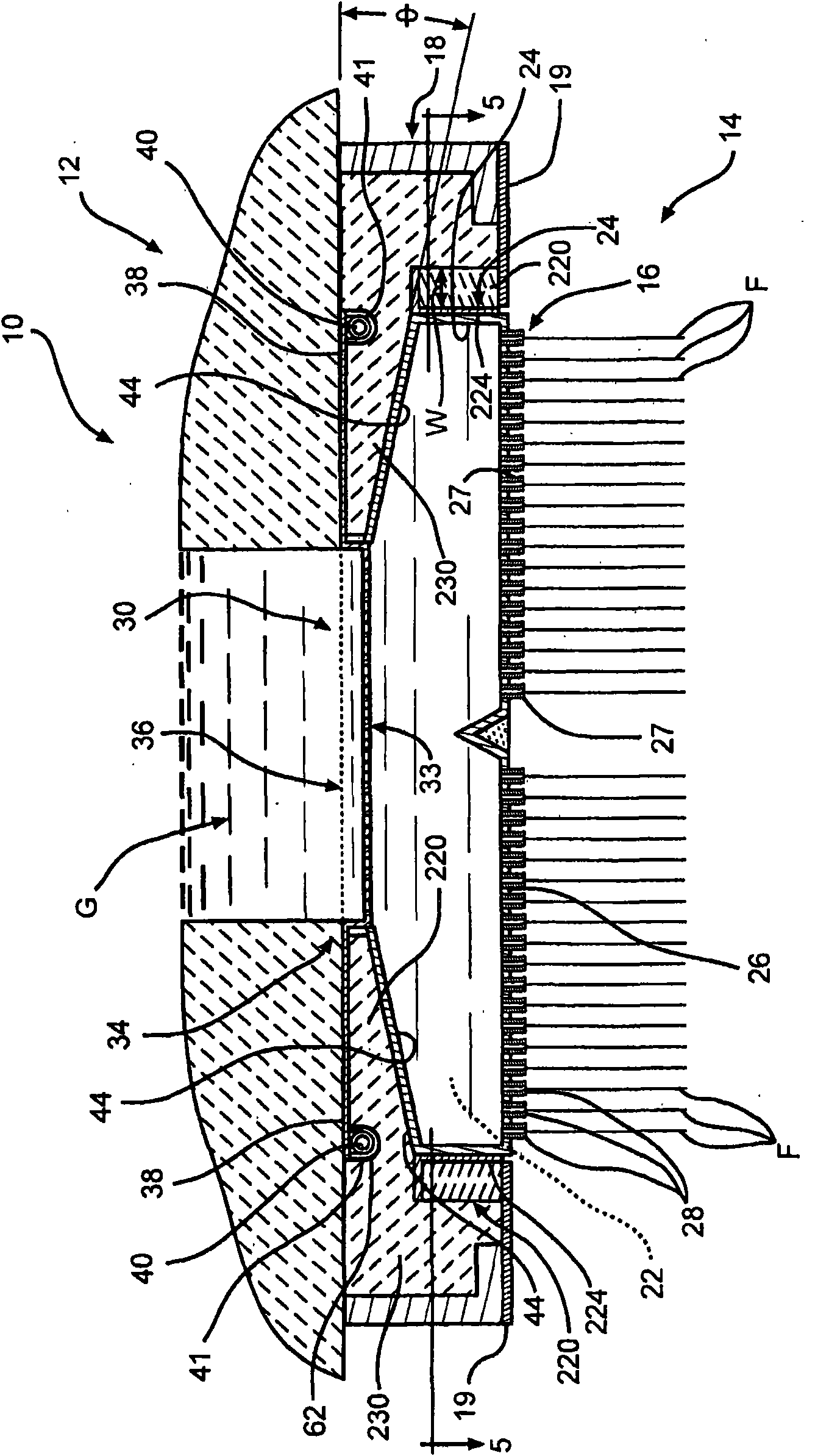

[0017] Referring now to the accompanying drawings, figure 1 One embodiment of a fiber forming assembly 10 comprising a breakout brick 12 and a breakout assembly 14 is shown. The bushing plate assembly 14 includes a bushing plate 16 and a frame 18 surrounding the bushing plate 16 . Bushing plate assembly 14 also includes a plurality of precast or sintered refractory material sections 20 disposed in the space between frame 18 and bushing plate 16, as in Figure 4 is schematically shown in , and will be further explained below.

[0018] The bushing 16 consists essentially of an electrically conductive material. In certain embodiments, bushing plate 16 takes the form of an elongated, generally rectangular metal box. Such as Figure 4 Shown schematically, the bushing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com