Wire drawing machine

A wire drawing machine and wire drawing technology, applied in the field of wire drawing machines, can solve the problems of difficulty in improving product quality, single metal material, difficulty in starting, etc., and achieve the effects of reducing production costs, improving system integration, and reducing power and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

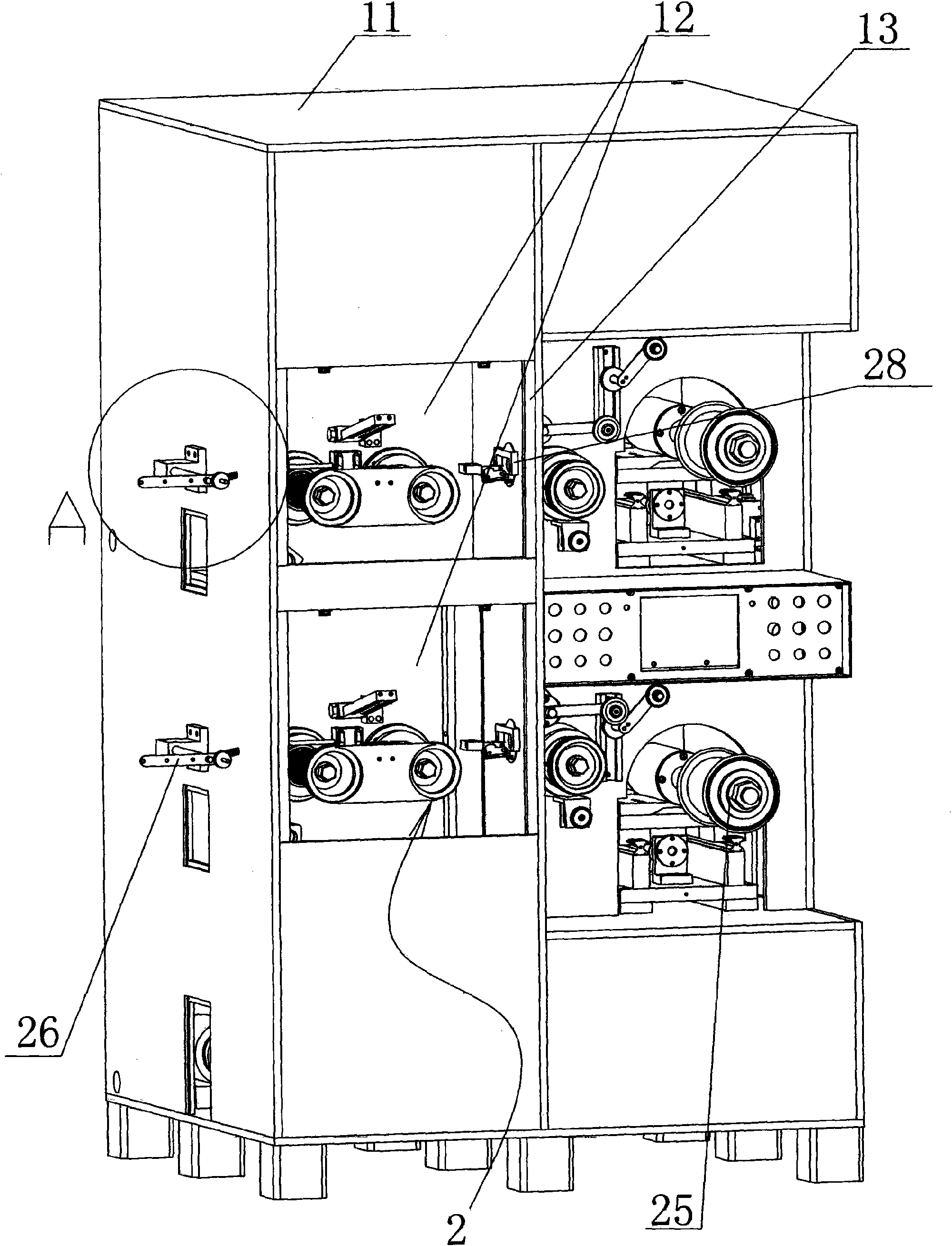

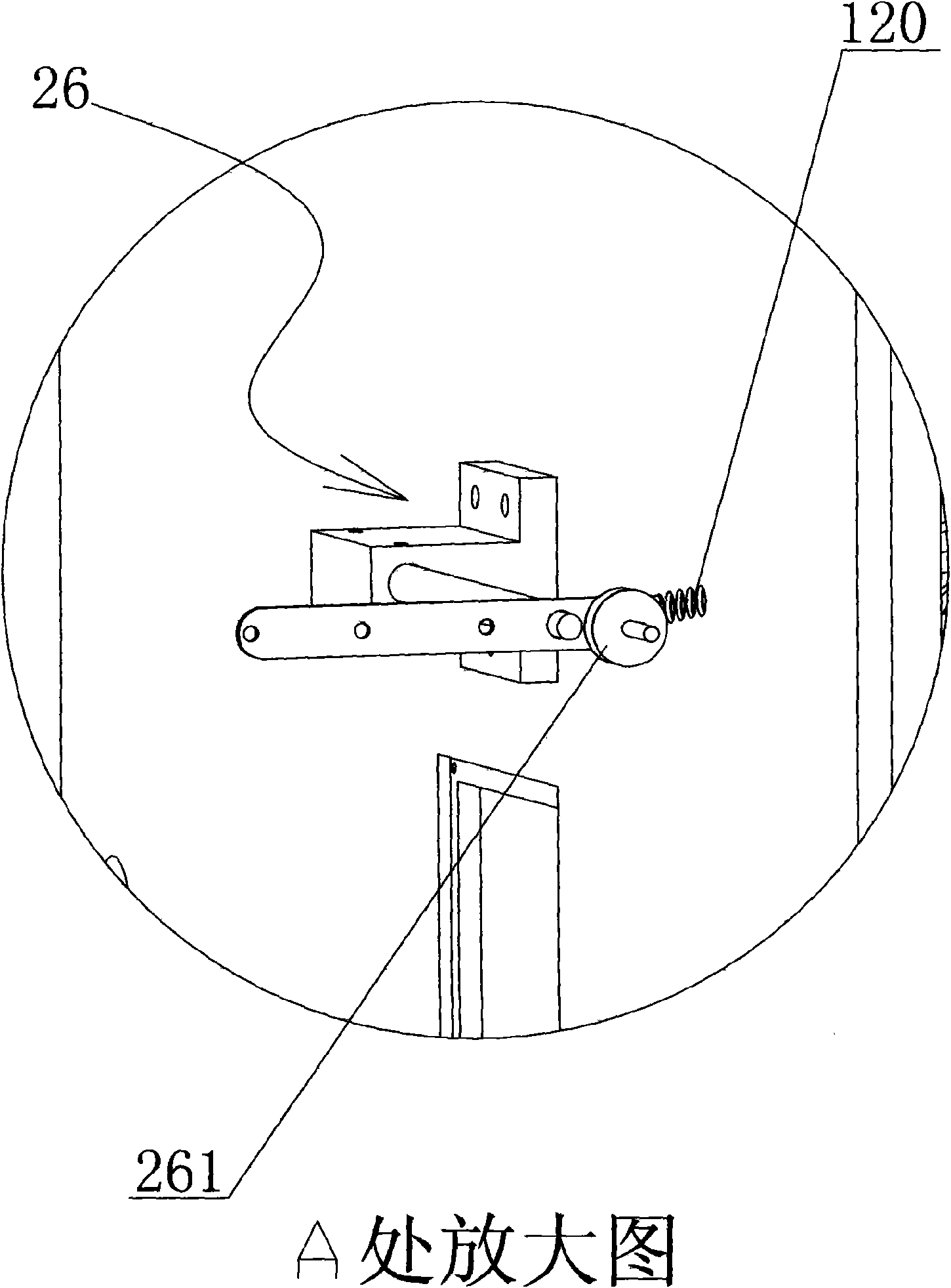

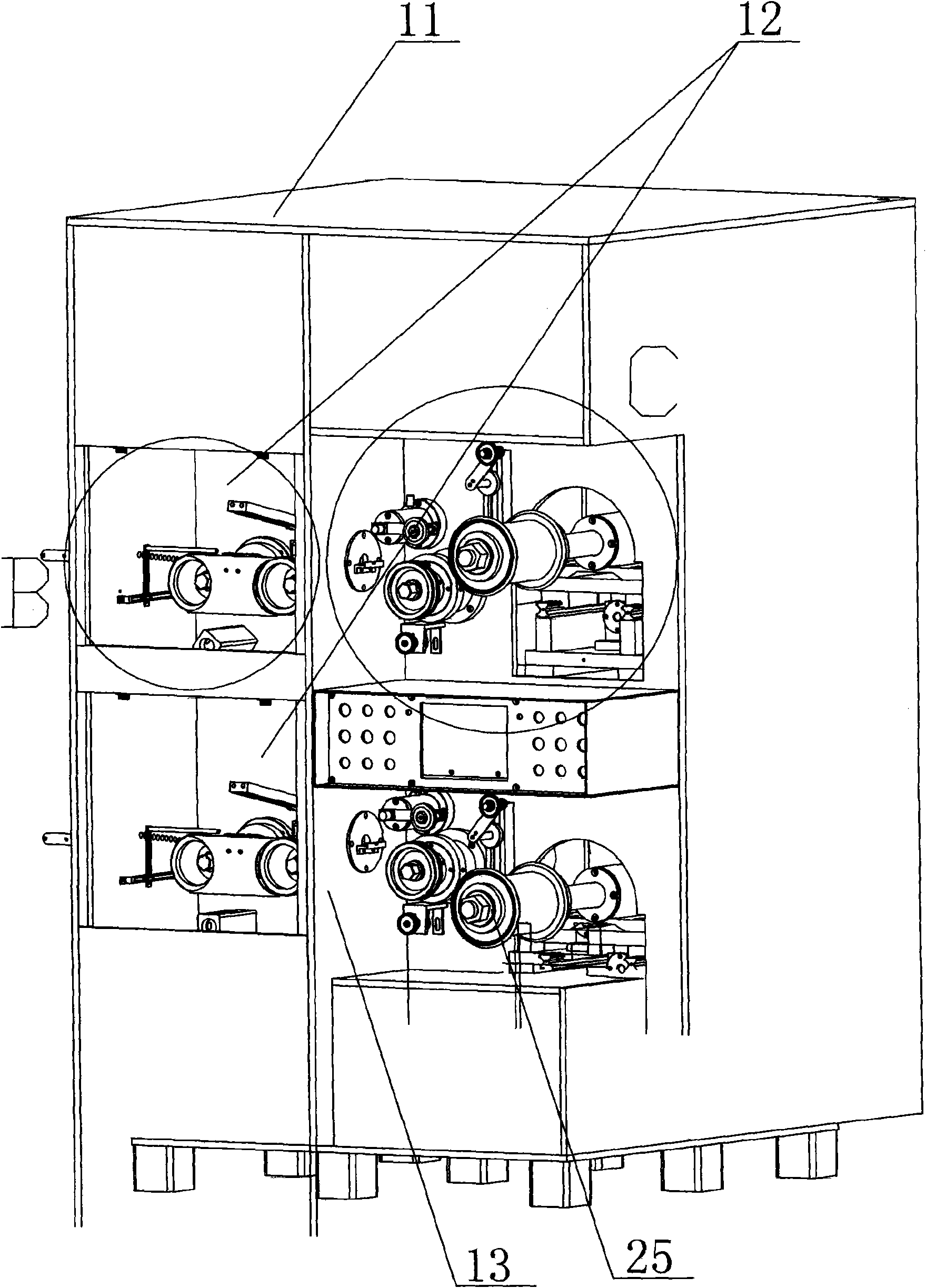

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0024] As shown in the figure, a wire drawing machine involved in the present invention includes a frame 11 and a plurality of wire drawing assemblies 2, the frame 11 includes a plurality of installation layers 12 arranged in parallel, and each wire drawing assembly 2 is correspondingly arranged on each of the above-mentioned In the installation layer 12, the wire drawing assembly 2 includes a main formwork 22 and the first tower pulley 21 and the second tower pulley 23 positioned on both sides of the main formwork 22, as well as the lead wheel set 24 and the take-up shaft 25, and the take-up shaft 25 is equipped with It is used to collect the thread into the thread tray. The first cone wheel 21, the main formwork 22, the second cone wheel 23, the lead wheel set 24 and the take-up shaft 25 are arranged in sequence.

[0025] In the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com