Hydraulic coupler type limited-slip differential

A technology of hydraulic coupling and anti-skid differential, which is applied in the direction of control devices, transportation and packaging, and vehicle parts, and can solve problems such as inapplicability to special road surfaces, poor car passability, and difficult steering of cars, and achieve increased Efficiency and flexibility, improved driving flexibility, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

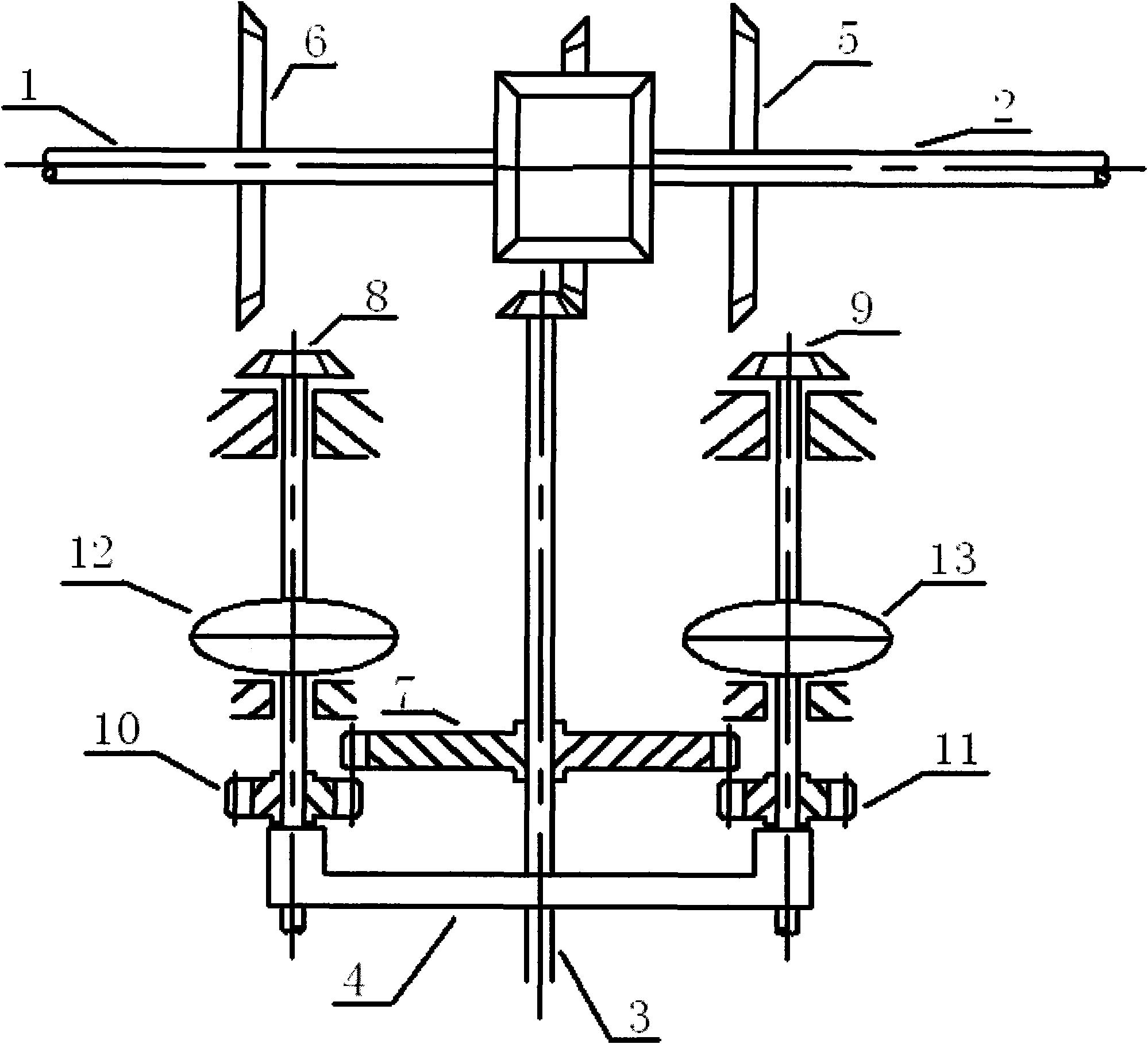

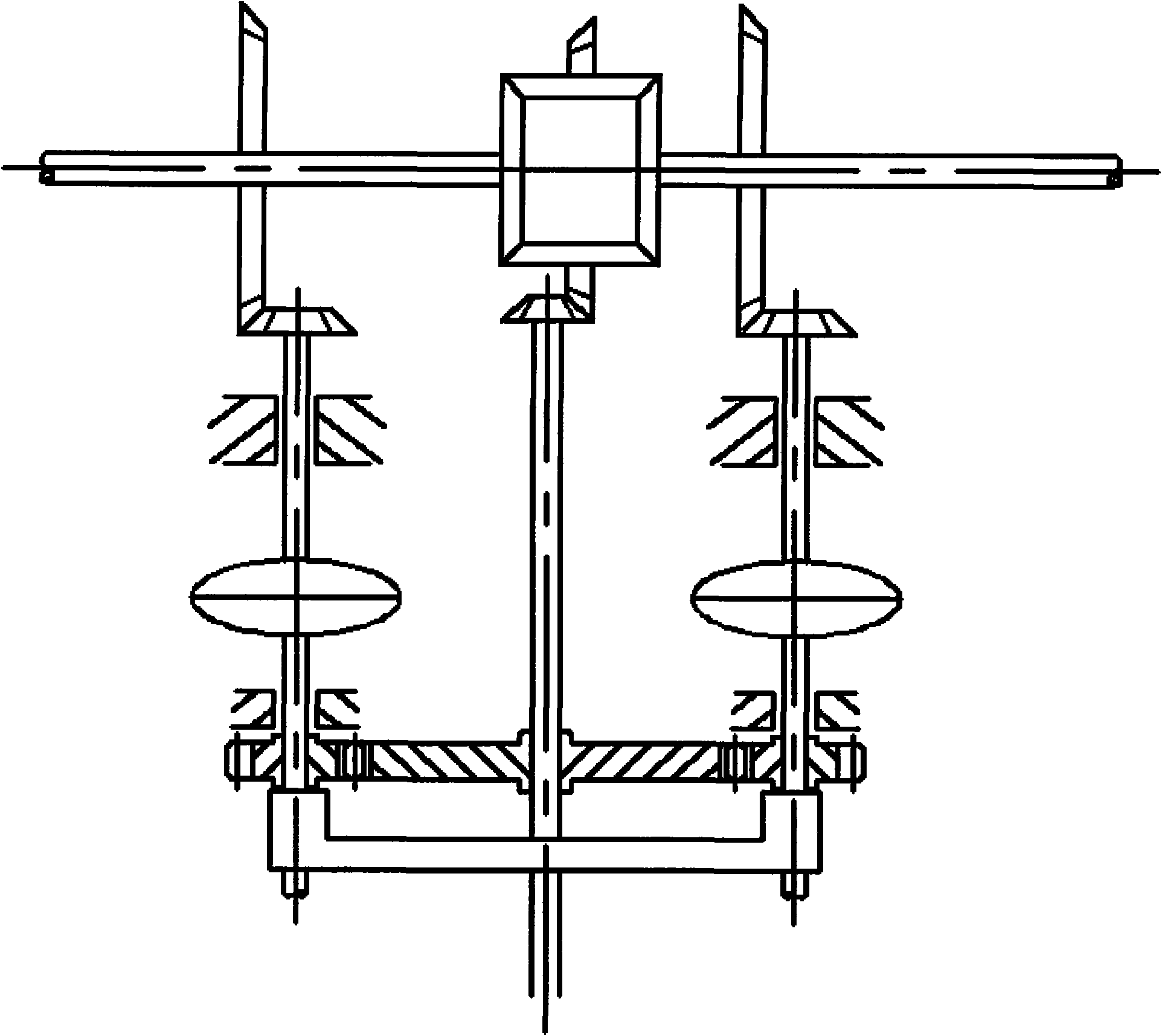

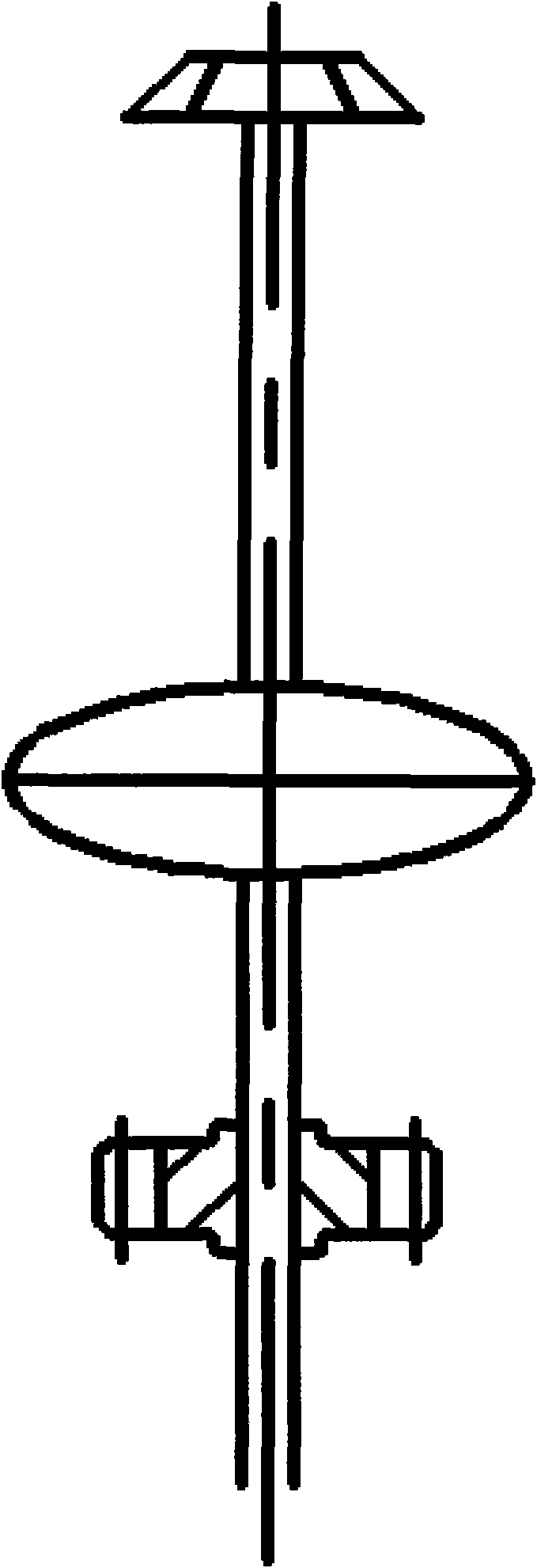

[0015] The structure and function of the present invention will be described below in conjunction with the drawings

[0016] see figure 1 , the left half shaft (2), the right half shaft (1) and the drive shaft (3) constitute a common gear differential.

[0017] Bevel gears (5) are fixed on the left half shaft (2), bevel gears (6) are fixed on the right half shaft (1), and gears (7) are fixed on the transmission shaft (3).

[0018] The coupling shaft of the hydraulic coupling is connected with the vehicle body through bearings, and the bevel gear (5) is usually disengaged from the bevel gear (9), bevel gear (6) and bevel gear (8) through the return spring, and the gear (7) disengage with gears (10), (11).

[0019] The gear shift slider (4) pushes the coupling shaft of the hydraulic coupling through the gear shift action, so that the bevel gear (5) and the bevel gear (9), the bevel gear (6) and the bevel gear (8), and the gear (7) and the gear (10), (11) enter meshing simulta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com