Method for controlling automatic leveling system of special vehicle

An automatic leveling and control method technology, applied in the field of control, can solve difficult problems such as high leveling accuracy and low production cost, complex control method, and a large amount of processing information, and achieve simple control method, high leveling accuracy, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

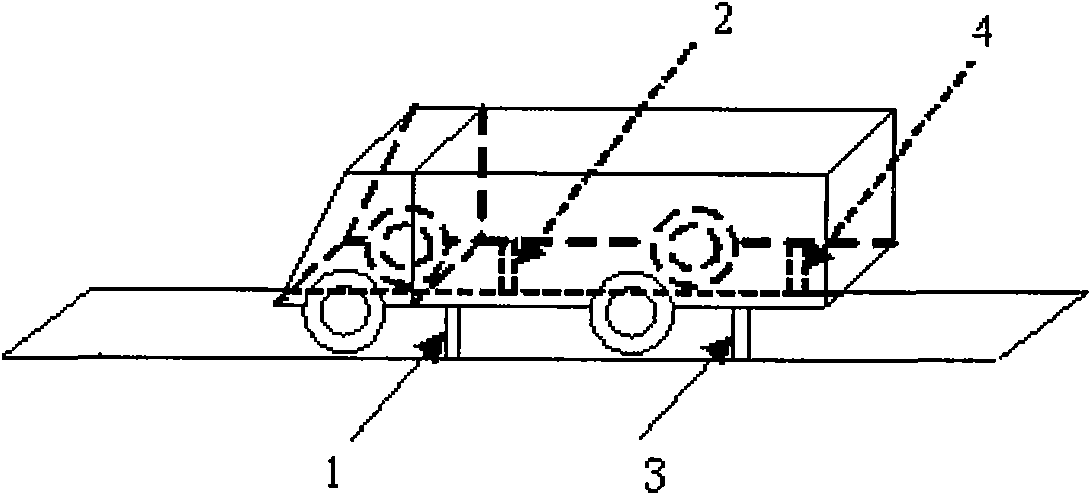

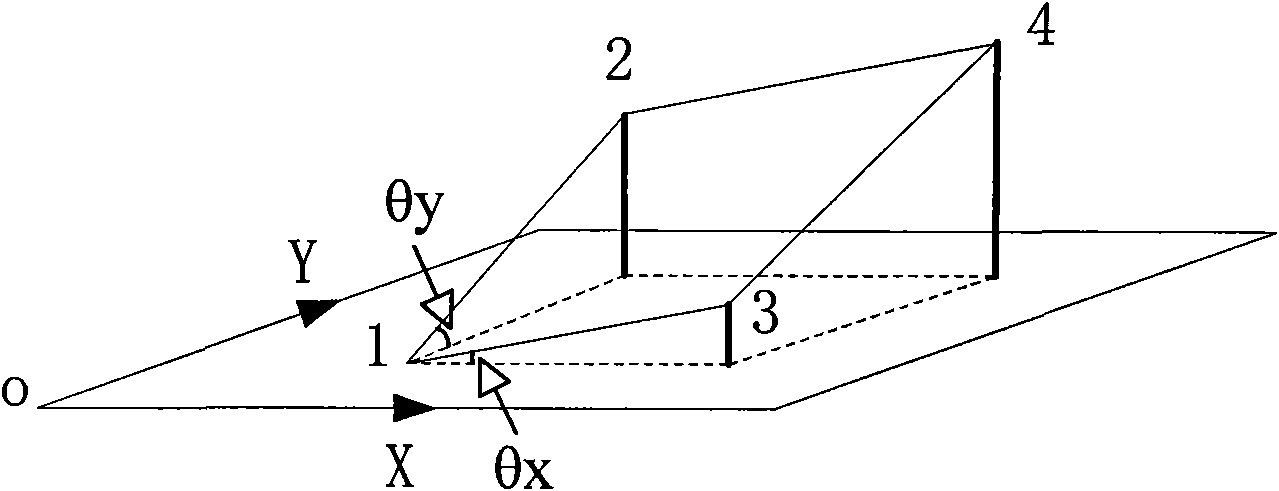

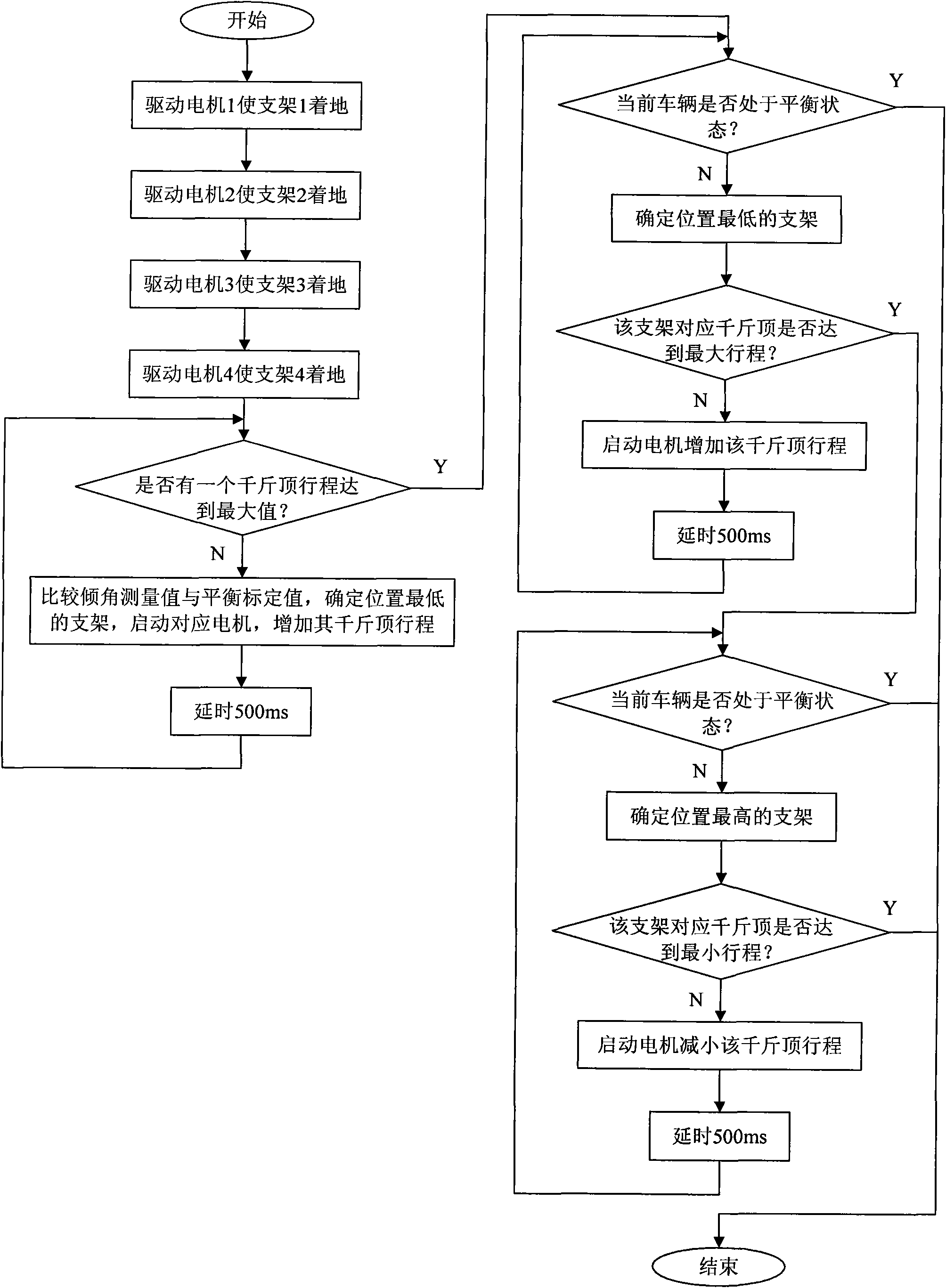

[0015] refer to figure 1 , figure 2 , image 3 As shown, the present invention proposes a new control method for the low-cost and low-complexity control requirements of the special vehicle automatic leveling system. Such as image 3 As shown, after the control system receives the leveling command, the microprocessor sends a control signal, which is transmitted to the drive circuit to drive the DC motor, so that the supports 1, 2, 3, and 4 are sequentially grounded (such as figure 1 shown), according to the state of the upper limit switch installed on the four jacks, it is judged whether one of the jack strokes has reached the maximum value, if not, then receive the corresponding X, Y of the current vehicle inclination detected by the dual-axis inclination sensor Axis horizontal inclination θx, θy (such as figure 2 shown), and the biaxial inclination va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com