Well test analysis control method for low permeability gas reservoir and method thereof

A control method and low-permeability technology, applied in earth-moving drilling, wellbore/well components, etc., to achieve the effect of easy promotion, saving test costs, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

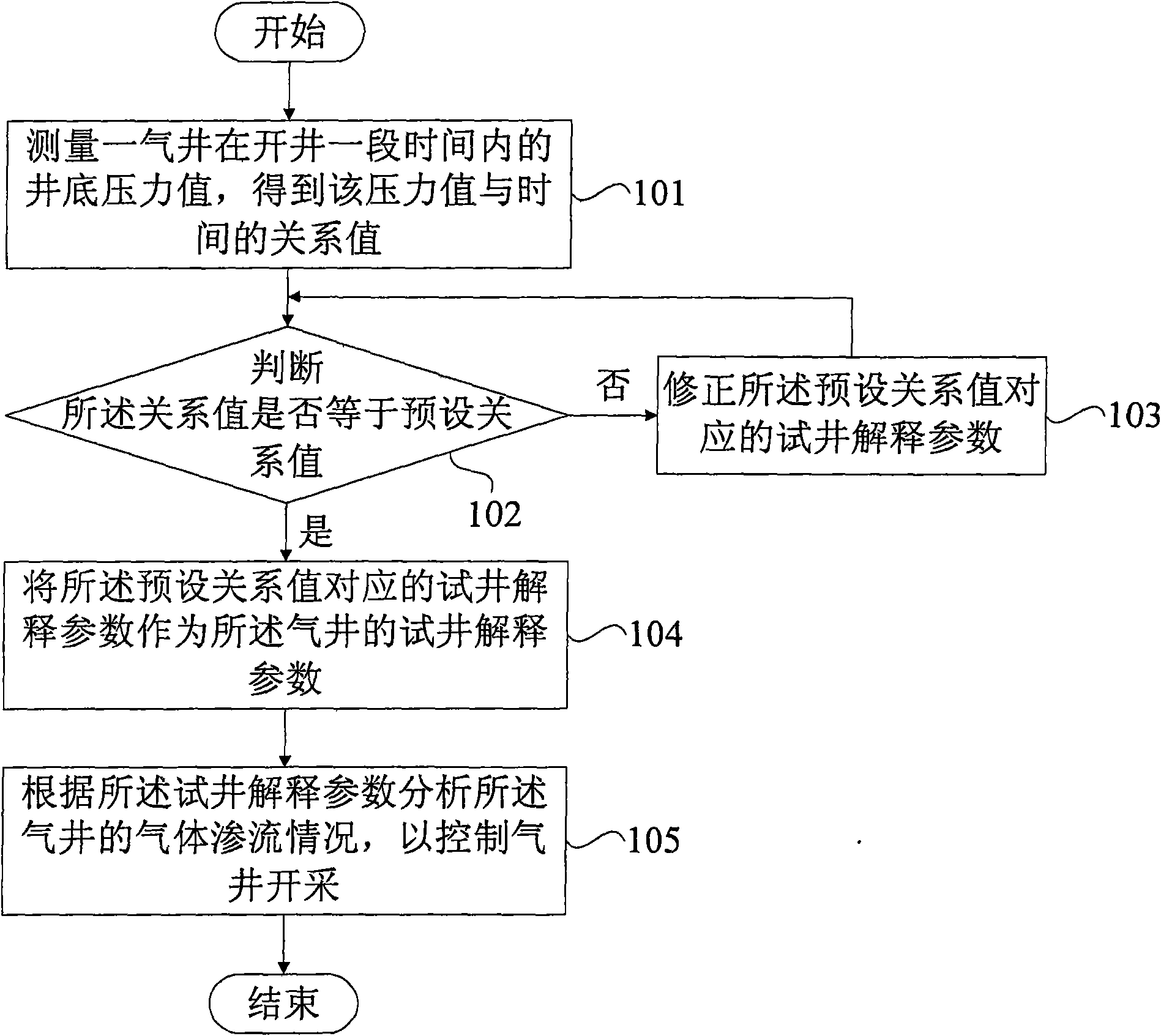

[0017] figure 1 It is a flow chart of the well test analysis and control method for low-permeability gas reservoirs in the embodiment of the present invention. The method in the embodiment of the present invention considers the influence of the slippage effect on the low-permeability gas reservoirs. The method includes the following steps:

[0018] 101: Measure the bottom hole pressure value of a gas well during a certain period of time, and obtain the relationship between pressure difference and time, that is, the pressure solution;

[0019] According to an embodiment of the present invention, the relationship includes a pressure difference versus time relationship and a derivative of the pressure difference versus time relationship.

[0020] According to the measurement step, the bottom hole pressure value of the gas well is obtained. How to obtain various parameters of the gas well according to the bottom hole pressure value so as to determine the production system of the g...

Embodiment 2

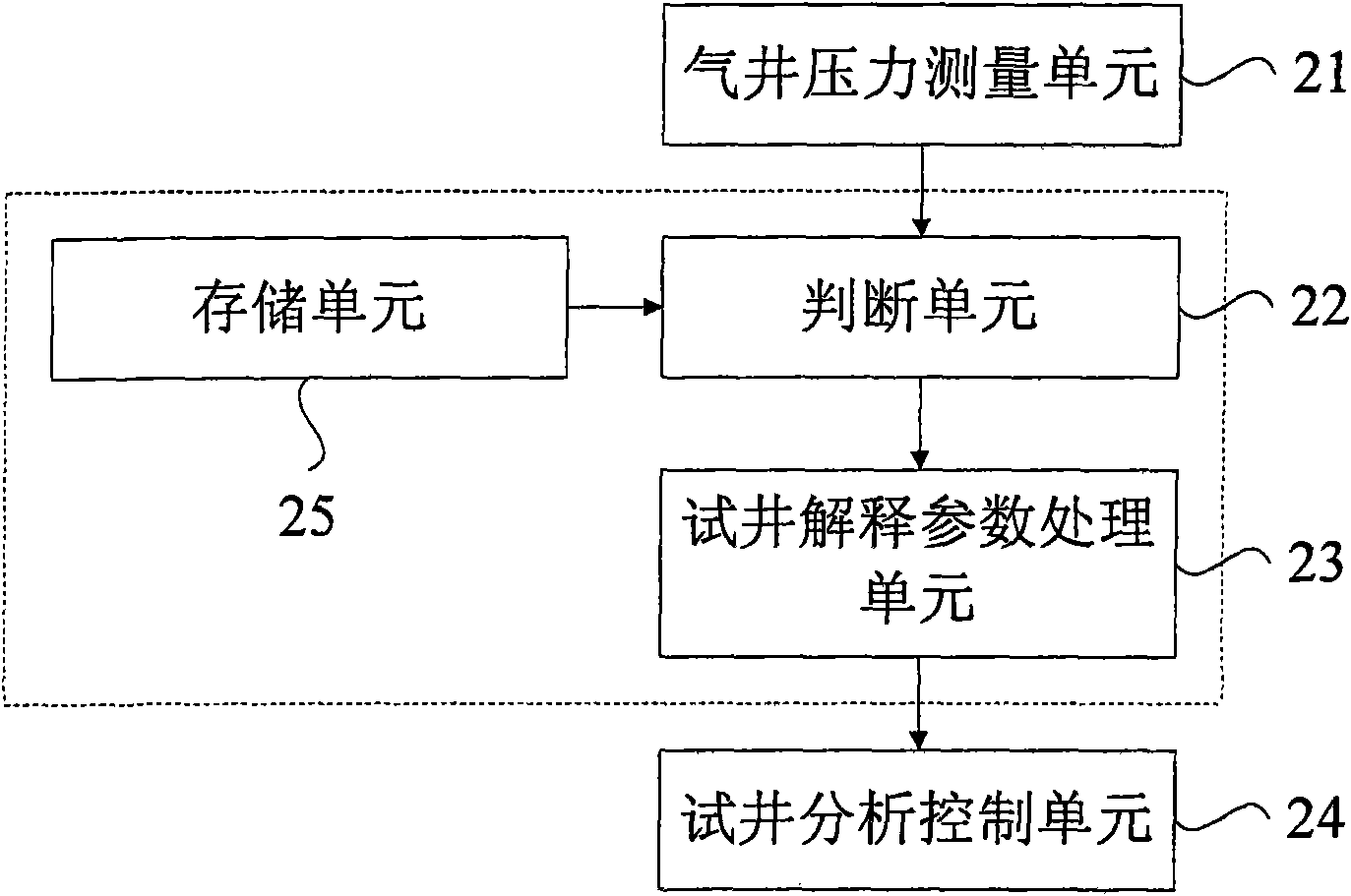

[0063] figure 2 It is a block diagram of a low-permeability gas reservoir well test analysis control system according to an embodiment of the present invention. The system mainly includes a gas well pressure measurement unit 21, a judgment unit 22, a well test interpretation parameter processing unit 23, and a well test analysis control unit 24, wherein:

[0064] The gas well pressure measurement unit 21 is used to measure the bottom hole pressure value of a gas well within a certain period of time, and obtain the relationship between the pressure difference and time, that is, the pressure solution. The relationship may include a pressure difference versus time relationship and a derivative of the pressure difference versus time relationship.

[0065] According to the embodiment of the present invention, the gas well pressure measurement unit 21 can be realized by a commonly used gas reservoir pressure measurement unit or measurement device, and the measurement results can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com