New loop optimization method of non-supercharged high-efficiency energy-saving internal-combustion engine

A cycle optimization, high-efficiency and energy-saving technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as unreasonable cycles of internal combustion engines, achieve the effects of increasing specific power, reducing exhaust loss, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

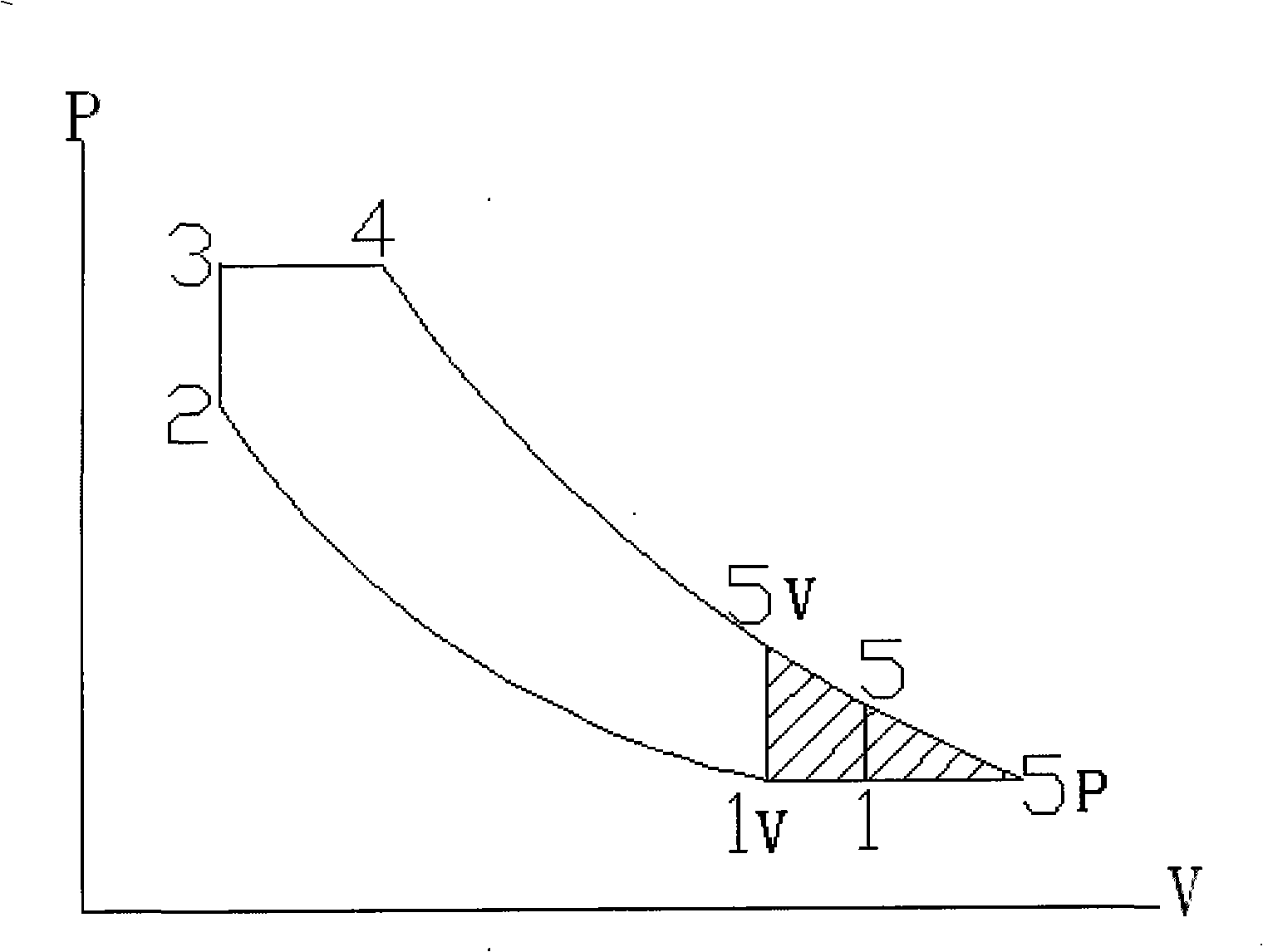

Method used

Image

Examples

Embodiment 1

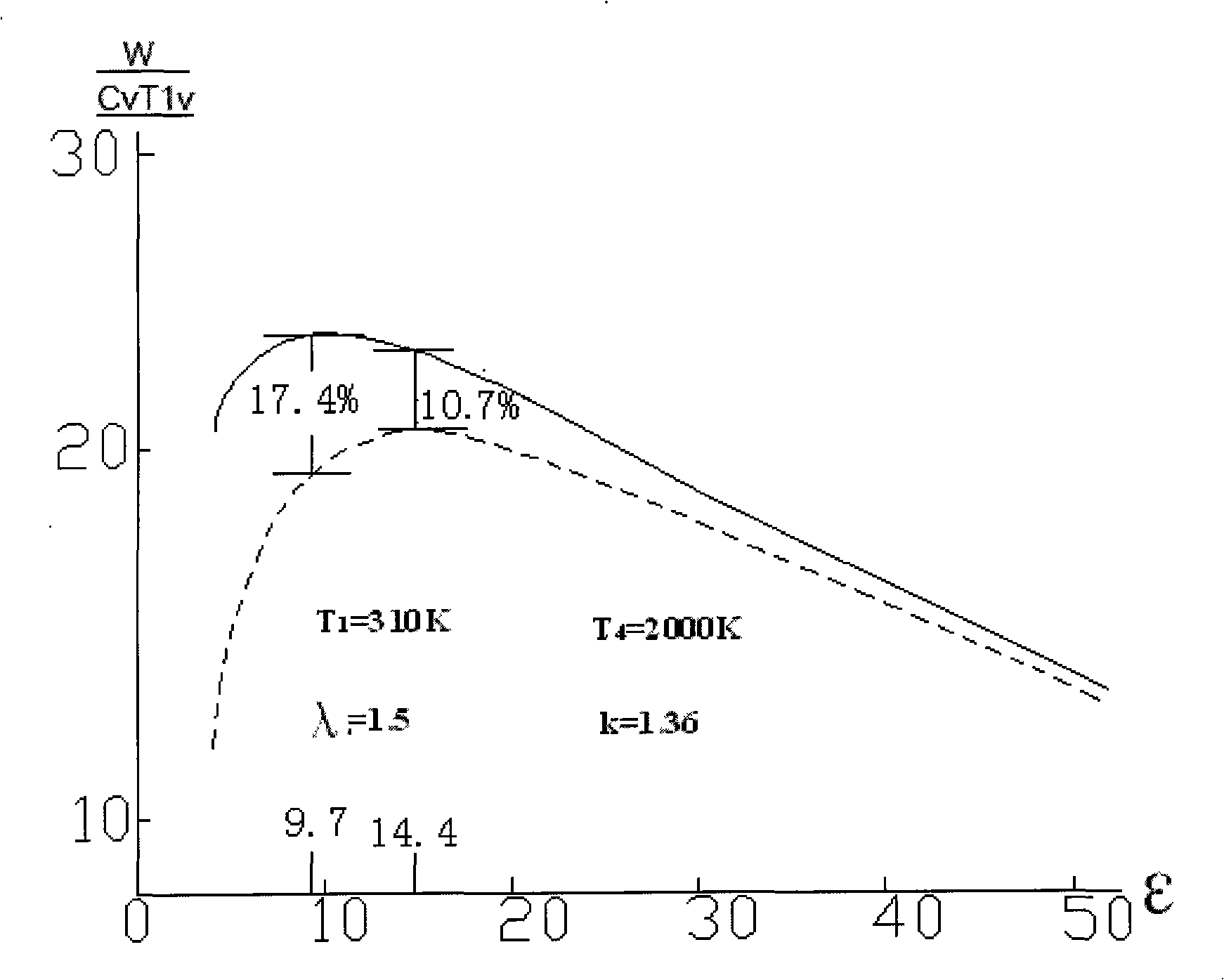

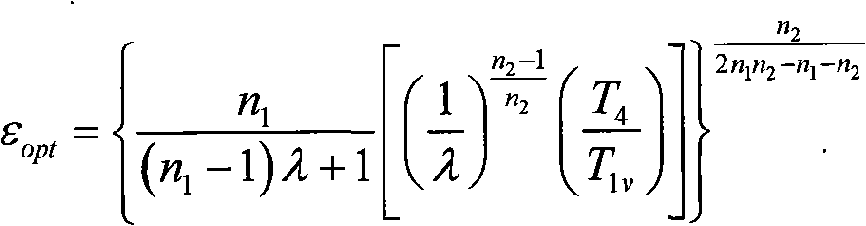

[0036] For a newly designed engine, the optimal compression ratio can be determined according to formula (2), where the variable index n 1 and n 2 It can be selected according to the empirical data of engines with similar performance, the temperature T of the starting point of working fluid compression 1v and the maximum gas temperature T 4 It can be determined according to the calculation method introduced in the relevant materials of "internal combustion engine", the value of the pressure rise ratio λ is selected between 1.25-2.2, and the thermodynamic parameters (c p , c v , k), you can refer to the book "Table of Thermophysical Properties of Liquids and Gases" edited by the inventor (Science Press, published in 1982).

Embodiment 2

[0038] For the existing internal combustion engine, its performance parameters can also be improved by changing the opening and closing angles of the intake and exhaust valves of the internal combustion engine so that the expansion ratio of the working medium is greater than the compression ratio in the variable process.

[0039] The specific method can be: reduce the exhaust valve opening angle γ in advance, and the minimum value of the γ value must ensure the pressure P of the gas at the end of expansion 5 and outside atmospheric pressure P a The ratio of should be slightly greater than or equal to the critical pressure ratio:

[0040] p 5 p a ≥ ( 2 k g + 1 ) ...

Embodiment 3

[0046] A single-cylinder engine has a bore of 100mm, a stroke of 115mm, a rated speed of 2200rpm, a rated power of 11.3kW, a fuel consumption rate of 245g / kW·h, a compression ratio of 17.5, an exhaust temperature of 873K, the intake valve opening angle α and exhaust The delayed closing angle δ of the valve is 15°CA, the delayed closing angle β of the intake valve and the early opening angle γ of the exhaust valve are both 43°CA. According to the theory of this patent, after reducing the γ angle to 20°CA, the fuel consumption rate of the engine can be reduced by 3%.

[0047]The invention overcomes the shortcoming that the expansion ratio of the high-temperature and high-pressure gas of the existing internal combustion engine is equal to the compression ratio of the low-temperature and low-pressure air, and it can make the high-temperature and high-pressure gas fully expand in the cylinder, thereby reducing the exhaust loss and greatly improving the working efficiency. The speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com