Method for Determination of Two-Phase Interface Area in Oil-Water Mixture

A measurement method and interface area technology, which is applied in the direction of measuring devices, surface tension analysis, surface/boundary effects, etc., can solve the problems of limited application of interface adsorption method, more serious influence of stirring conditions, and inestimable errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

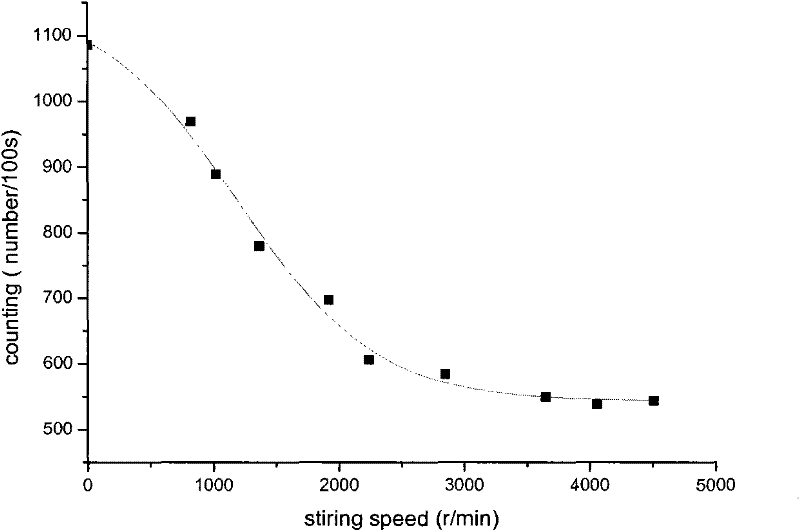

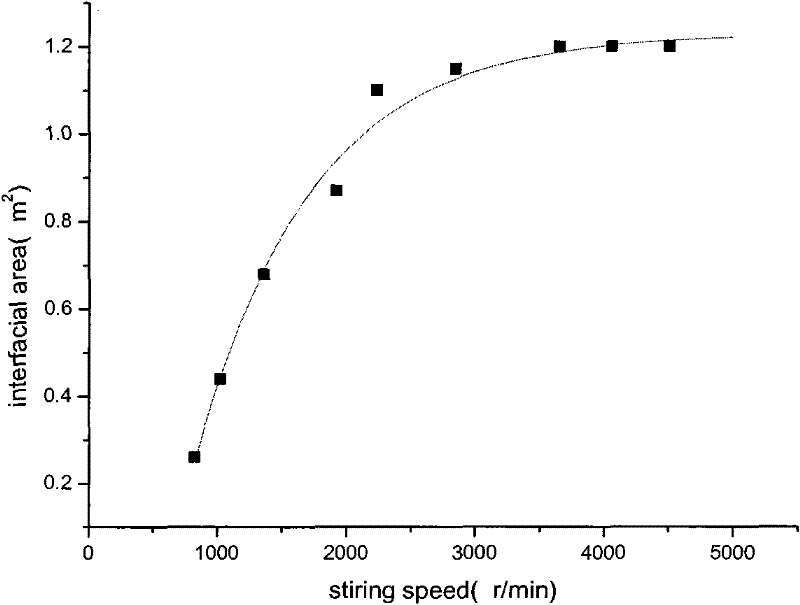

[0028] At t=21°C, 30% TBP-kerosene and 1.0mol / L HNO 3 The value of the interface area between the two phases at different rotational speeds when the solution system is stirred at high speed. The volume of the aqueous phase is 15.0 mL, the volume of the organic phase is 30.0 mL, the volume of the reaction vessel is 3.0 cm×3.0 cm×6.0 cm, and the stirring blade is in the water phase. In this stirring system, 30% TBP-kerosene is the dispersed phase and belongs to low viscosity material.

[0029] Its operation process is as follows.

[0030] 1) The measured real system (30%TBP-kerosene+1mol / L HNO 3 ) The interfacial tension in ) is 9.2mN / m.

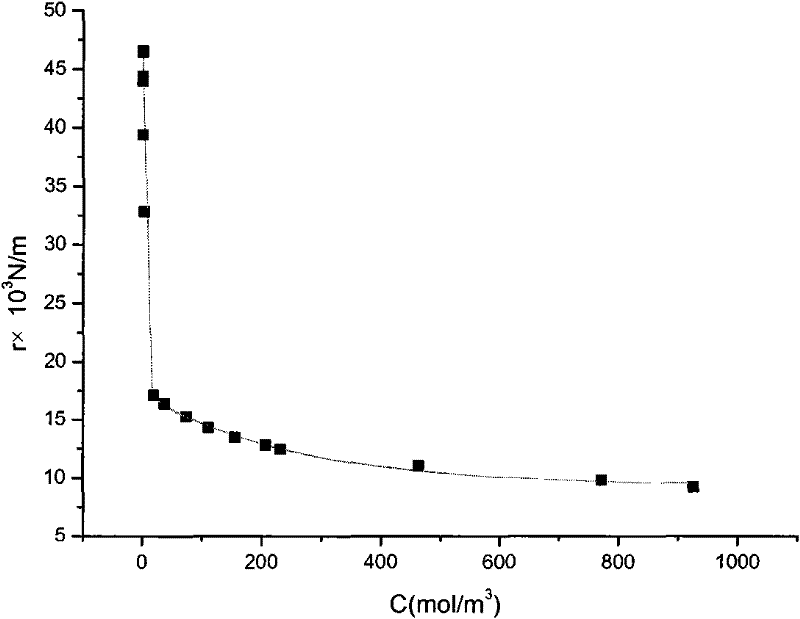

[0031] 2) Prepare TBP-kerosene solutions containing different concentrations of TBP, and measure the different concentrations of TBP-kerosene solutions and 1.0mol / L HNO 3 Interfacial tension of aqueous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com