Catalyst-free acid gel and development method thereof

A catalyst and acid glue technology, applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem that titanium catalysts are prone to yellowing, cannot be used in contact with food, and affect the use effect of silicone rubber sealants, etc. problem, to achieve good curing effect, good curing effect and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

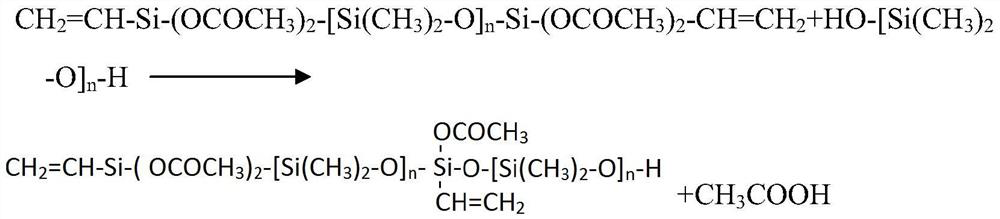

Method used

Image

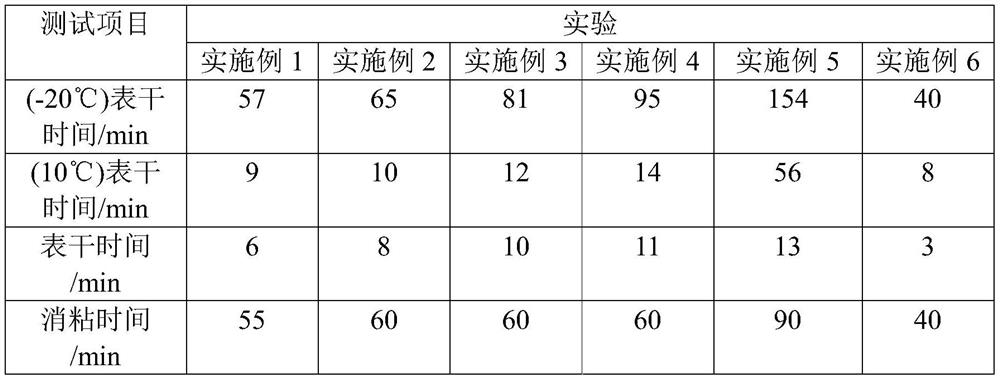

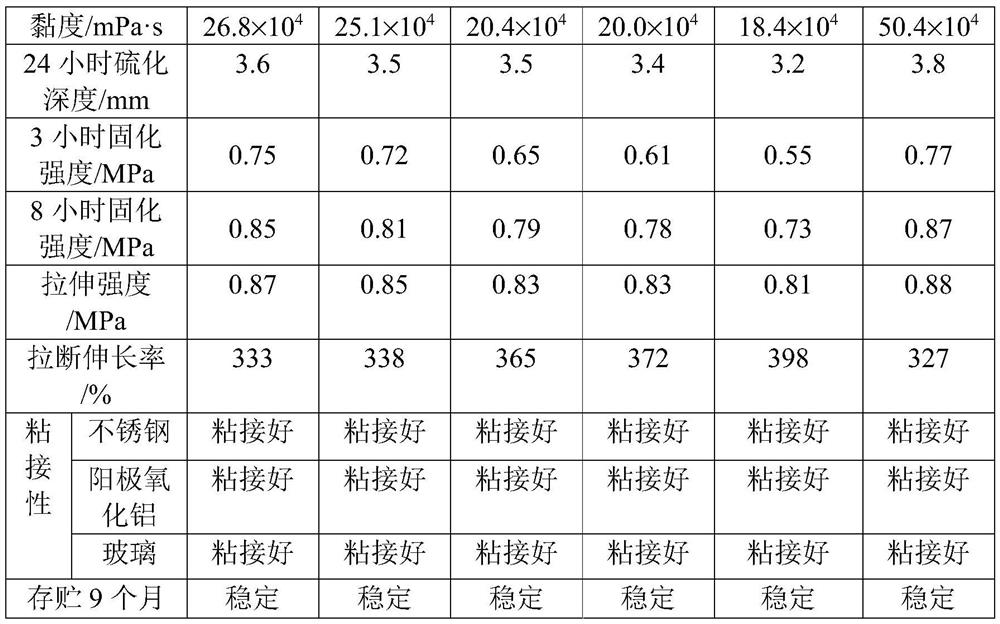

Examples

Embodiment 1

[0066] A catalyst-free acid gel. The raw materials are prepared in parts by weight, including: 100 parts of α, ω-dihydroxy polydimethylsiloxane, 6 parts of fumed white carbon black, 0.5 parts of di-tert-butoxydiacetoxysilane 1 part, 1 part of methyltriacetoxysilane, 4 parts of vinyltriacetoxysilane.

[0067] α, ω-Dihydroxypolydimethylsiloxane, CAS No. 31692-79-2, purchased from Dow Corning; Fumed silica, purchased from Cabot; Methyltriacetoxysilane, purchased from Purchased from Jingzhou Jianghan Fine Chemical Co., Ltd.; Vinyltriacetoxysilane was purchased from Jingzhou Jianghan Fine Chemical Co., Ltd.

[0068] A method for developing catalyst-free acid gel, comprising the following steps:

[0069] S1: Add α,ω-dihydroxy polydimethylsiloxane to the vacuum planetary mixer, stir for 2 minutes, then add methyltriacetoxysilane and vinyltriacetoxysilane and stir for 20 minutes;

[0070] S2: Add fumed silica and di-tert-butoxydiacetoxysilane to the step S1, and stir for 10 minutes ...

Embodiment 2

[0072] A catalyst-free acid gel. The raw materials are prepared in parts by weight, including: 100 parts of α, ω-dihydroxy polydimethylsiloxane, 6 parts of fumed white carbon black, 0.5 parts of di-tert-butoxydiacetoxysilane Parts, 2 parts of methyltriacetoxysilane, 3 parts of vinyltriacetoxysilane.

[0073] α, ω-Dihydroxypolydimethylsiloxane, CAS No. 31692-79-2, purchased from Dow Corning; Fumed silica, purchased from Cabot; Methyltriacetoxysilane, purchased from Purchased from Jingzhou Jianghan Fine Chemical Co., Ltd.; Vinyltriacetoxysilane was purchased from Jingzhou Jianghan Fine Chemical Co., Ltd.

[0074] A method for developing a catalyst-free acid gel refers to Example 1.

Embodiment 3

[0076] A catalyst-free acid gel. The raw materials are prepared in parts by weight, including: 100 parts of α, ω-dihydroxy polydimethylsiloxane, 6 parts of fumed white carbon black, 0.5 parts of di-tert-butoxydiacetoxysilane Parts, 3 parts of methyltriacetoxysilane, 2 parts of vinyltriacetoxysilane.

[0077] α, ω-Dihydroxypolydimethylsiloxane, CAS No. 31692-79-2, purchased from Dow Corning; Fumed silica, purchased from Cabot; Methyltriacetoxysilane, purchased from Purchased from Jingzhou Jianghan Fine Chemical Co., Ltd.; Vinyltriacetoxysilane was purchased from Jingzhou Jianghan Fine Chemical Co., Ltd.

[0078] A method for developing a catalyst-free acid gel refers to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com