Vertical parting molding machine

A vertical parting and molding machine technology, applied in the field of foundry machinery, can solve problems such as complex sand mold output structure, uneven sand mold compaction, increased pouring labor intensity, etc., to achieve flexible equipment layout, avoid lax fit, The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The vertical parting molding machine of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

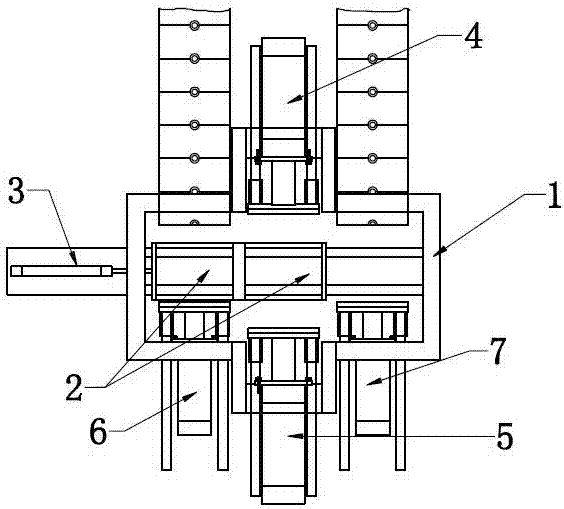

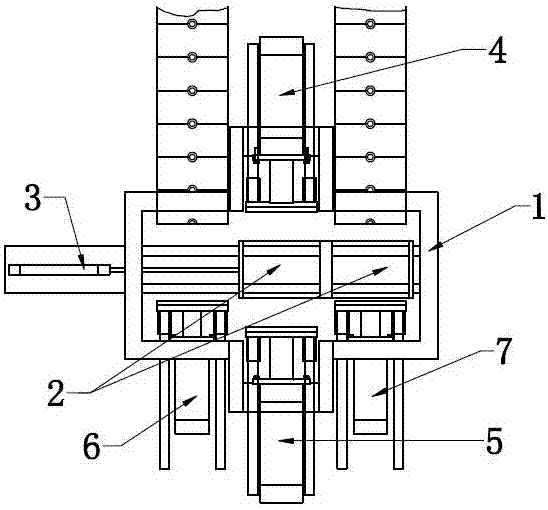

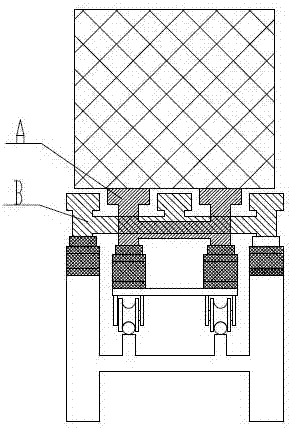

[0015] As shown in the figure, the vertical parting molding machine of the present invention includes a frame 1 and a sand chamber 2, and also includes a sand shooting mechanism capable of shooting sand into the sand chamber 2 and a conveying track capable of transporting the sand chamber 2. The sand chamber 2 is provided with There are two, the two sand chambers are arranged side by side in the frame 1, and one side of the frame 1 is provided with a sand chamber moving mechanism 3 that can push the double-chamber sand chambers to move in the horizontal direction, and the upper and lower sides of the frame 1 are respectively An upper sand mold compacting mechanism 4 and a lower mold compacting mechanism 5 located in the middle part of the frame are provided, and a front sand mold moving mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com