Numerical value simulation method for spot welding connection and failure thereof

A numerical simulation and spot welding technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems that the welding spot model grid does not consider the feasibility of engineering application, and it is difficult to practically apply the value, so as to avoid Effects of complexity, improved precision, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

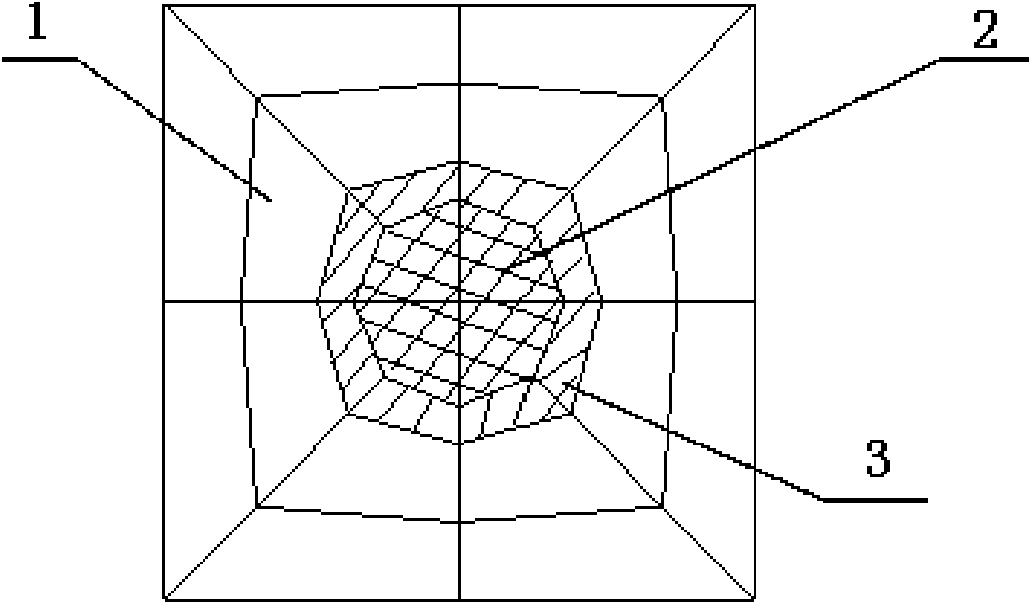

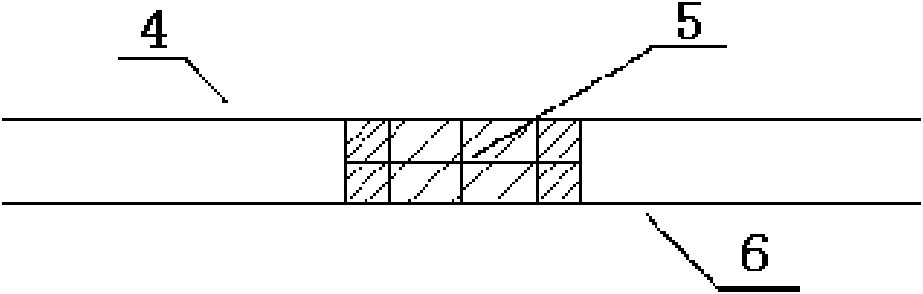

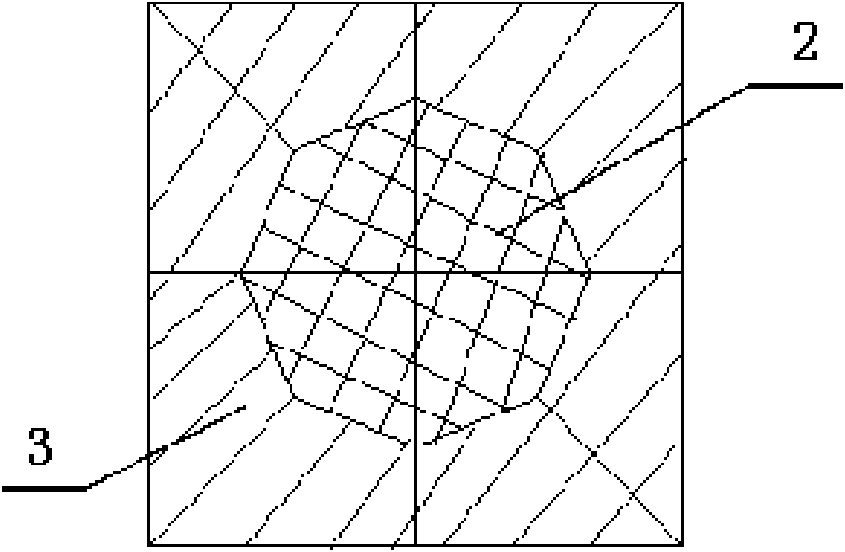

[0065] The specific construction scheme of the solder joint model of the present invention is: according to the structural characteristics of the solder joints divided into two regions, the nugget area and the heat-affected zone due to the change of material properties, the volume grid and the shell grid are used to establish the structure of the weld joint model. The solder joint finite element model composed of the nuclear area and the heat-affected zone provides a targeted implementation basis for the setting of solder joint failure parameters. This method also proposes specific construction rules for the formation of the solder joint model grid, which is suitable for The programming is automatically realized, and the specific steps for establishing the solder joint model are as follows:

[0066] The first step is to determine the shape and size of the grid in the weld nugget area: the weld nugget area is composed of one or more layers of grids, and each layer is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com