Method of monitoring planarization process of medium

A flattening and dielectric technology, which is applied in the field of monitoring the flattening process of the medium, can solve the problems of medium over-etching, inaccurate monitoring, and low repeatability, and achieve the effects of avoiding overhead, stabilizing the process, and improving monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

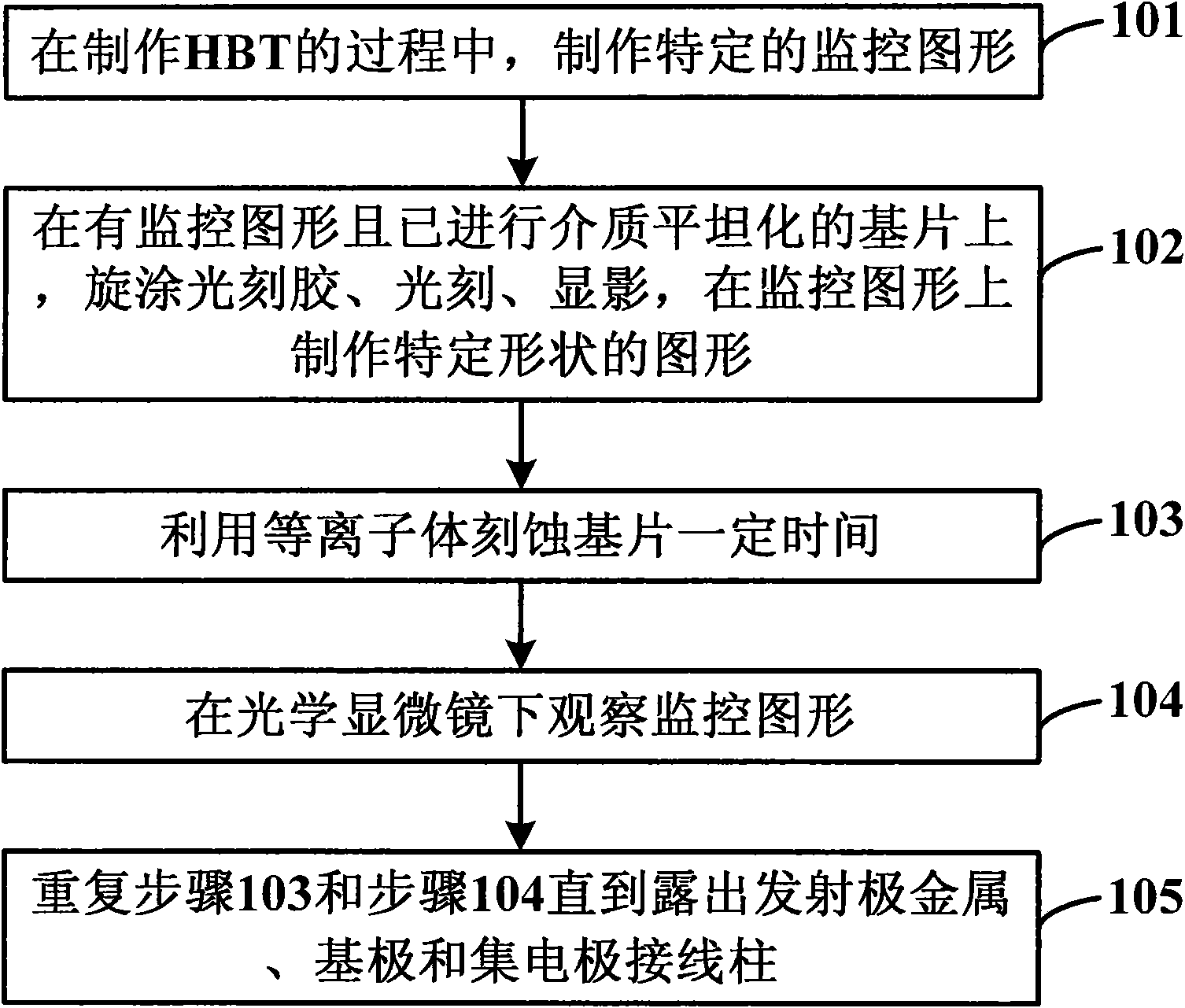

[0034] Such as figure 1 as shown, figure 1 A flowchart of a method for monitoring a medium flattening process provided by the present invention, the method includes the following steps:

[0035] Step 101: during the process of making HBT, make specific monitoring graphics;

[0036] Step 102: Spin-coat photoresist, photolithography, and development on the substrate with the monitoring pattern and the medium has been planarized, and make a pattern of a specific shape on the monitoring pattern;

[0037] Step 103: using oxygen or plasma containing oxygen to etch the substrate for a certain period of time;

[0038] Step 104: observe the monitor pattern under an optical microscope;

[0039] Step 105: Repeat steps 103 and 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com