Powder pumps for vacuum filling

一种粉末、粉末流的技术,应用在向粉末涂覆设备领域,能够解决粉末结块缺陷等问题,达到简化结构的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

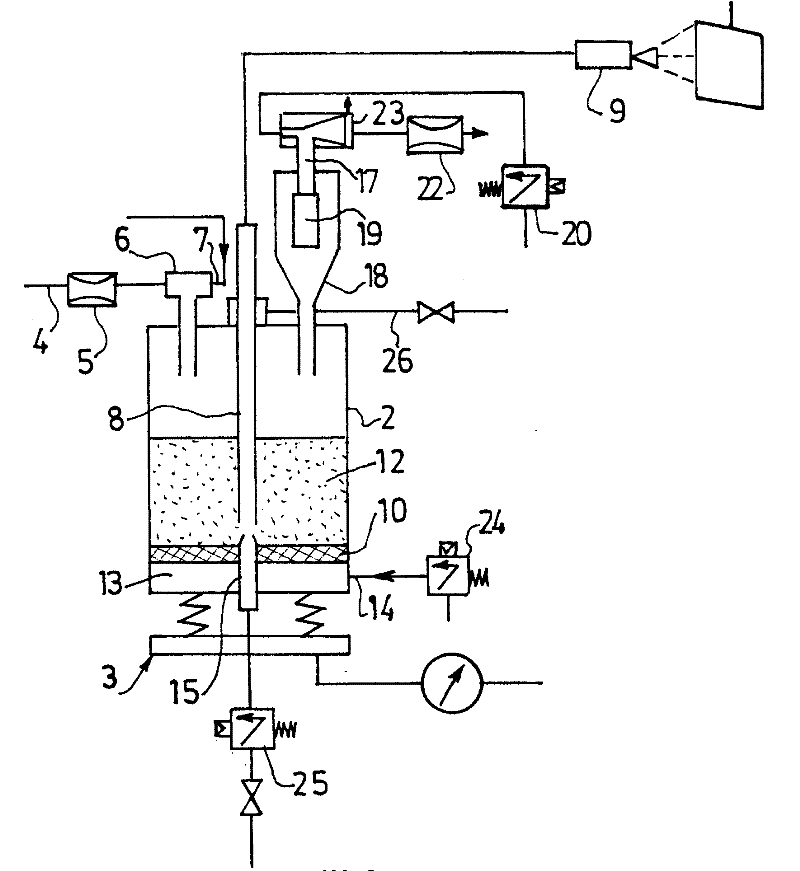

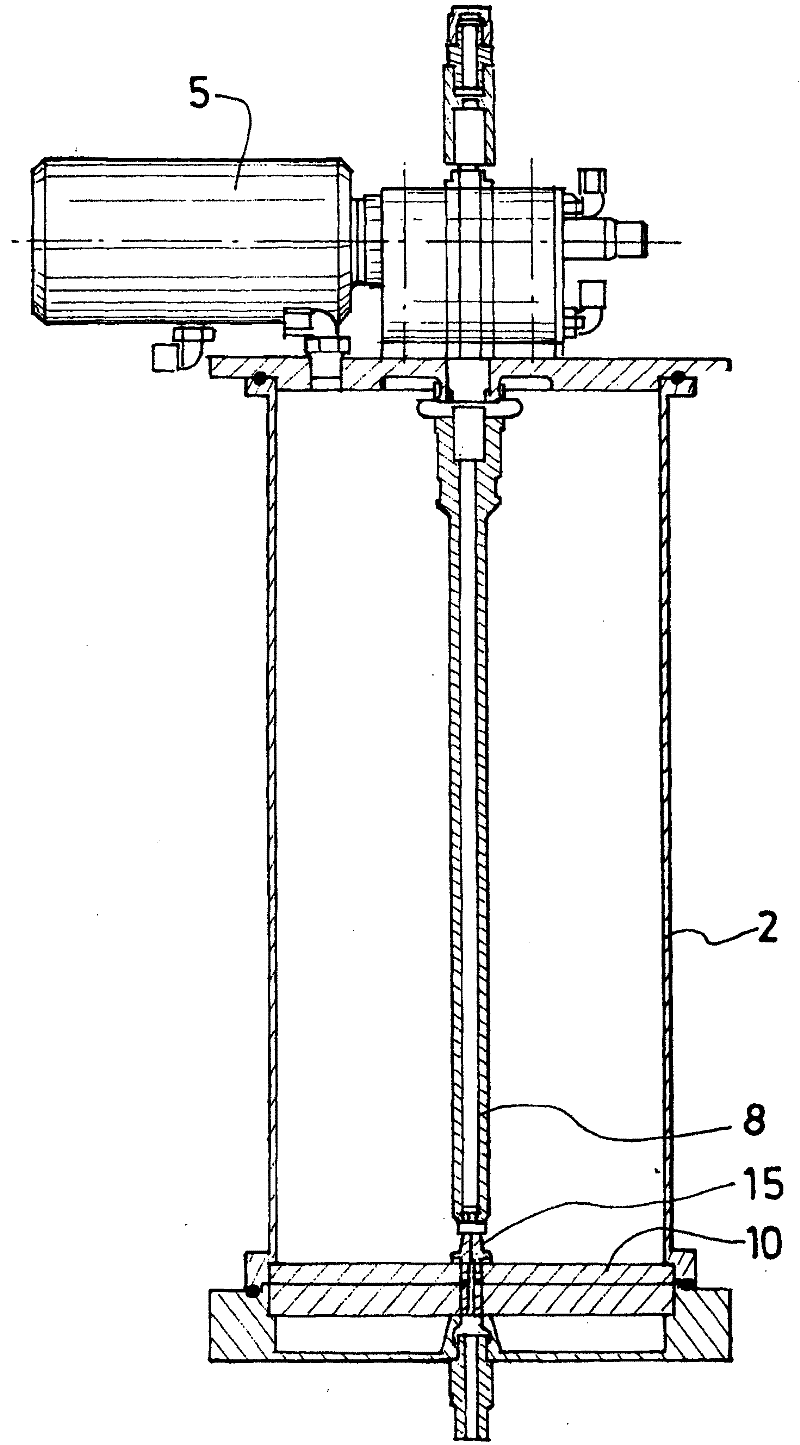

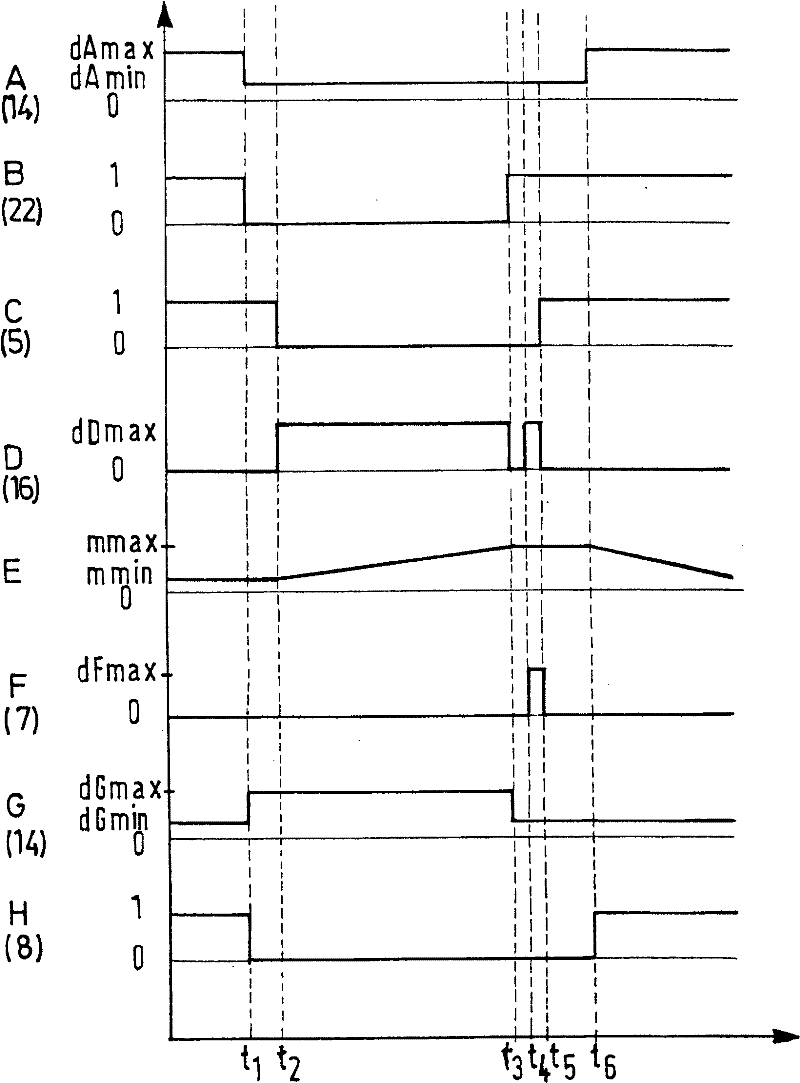

[0052] Such as figure 1 and figure 2 As shown, the powder supply system for a powder coating plant according to the invention comprises a tank 2 for containing powder. The system comprises means for detecting the amount of powder in the tank 2 , for example consisting of means 3 for weighing the mass of the tank 2 .

[0053] The system also includes a transfer device for transferring the powder into the tank. The conveying device includes a conveying pipe 4 for conveying powder to the tank 2 and a supply valve 5 for blocking the powder conveying pipe 4 . The supply valve is a pinch valve type.

[0054] The transfer pipe 4 is connected downstream of a loading device, not shown, in particular a filling container.

[0055] The transfer pipe 4 is arranged approximately horizontally and the powder supply valve 5 is arranged near the horizontal section of the pipe, which prevents compaction of the powder near the valve 5 due to gravity.

[0056]At the downstream end of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com