Adhesive compound, method for modifying adhesive and product made from the modified adhesive

A composition and technology of silicon pressure-sensitive adhesives, applied in the directions of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of unsatisfactory application, weak bonding strength of silicone materials, etc., and achieve good bonding the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

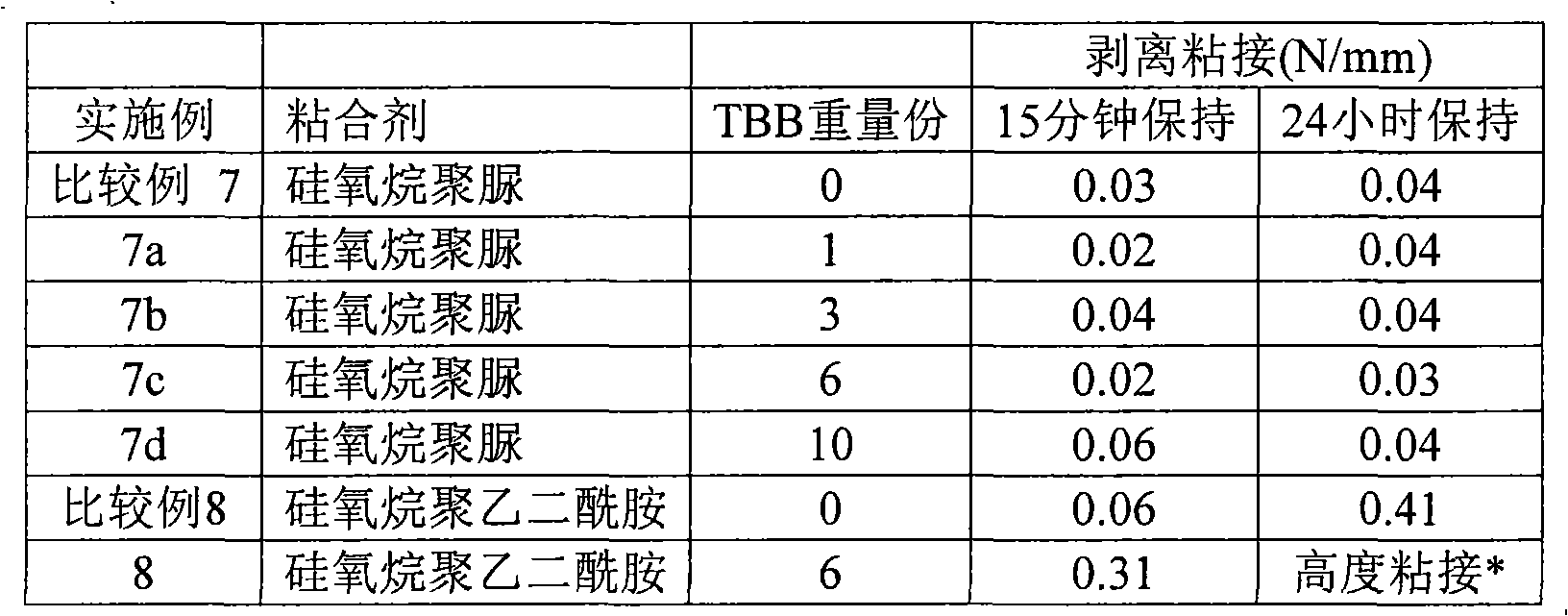

Examples

Embodiment 1

[0040] Trimethyl borate (3 parts by weight) and Degussa DCLBP-50-PSI (6 parts by weight) were uniformly dispersed in a solution containing 100 parts by weight of ShinEtsu KRT-002 polydimethylsiloxane pressure-sensitive adhesive by stirring. The resulting pressure-sensitive adhesive composition having a solids content of 40% was then coated on a 0.025 mm PET film and immediately dried at 70° C. for 1 minute. The dried glue was then cured at 165°C for 2 minutes. The thickness of the obtained dry glue was 0.040mm.

Embodiment 2

[0042]Trimethyl borate (5 parts by weight) and CAT-PL-50T catalyst (ShinEtsu) (0.83 parts by weight) were added to a solution containing 100 parts by weight of ShinEtsu KR3700 polydimethylsiloxane pressure-sensitive adhesive, and in Stir to disperse evenly. The resulting pressure-sensitive adhesive composition having a solids content of 40% was then coated on a 0.025 mm PET film and immediately dried at 70° C. for 1 minute. The dried glue was then cured at 130°C for 2 minutes. The thickness of the obtained dry glue was 0.040mm.

Embodiment 3

[0044] Tributyl borate (28 parts by weight) and A75 (3 parts by weight) was added to a solution containing 100 parts by weight of Momentive PSA610 polydimethylsiloxane pressure-sensitive adhesive, and dispersed evenly under stirring. The resulting pressure-sensitive adhesive composition having a solids content of 40% was then coated on a 0.025 mm PET film and immediately dried at 70° C. for 1 minute. The dried glue was then cured at 177°C for 2 minutes. The thickness of the obtained dry glue was 0.040 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com