Irregularly shaped multi-land notch groove drill rod

A special-shaped and drill pipe technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of mine safety loss, hidden danger, lost drill pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

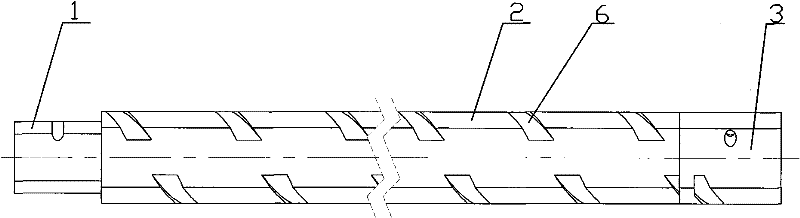

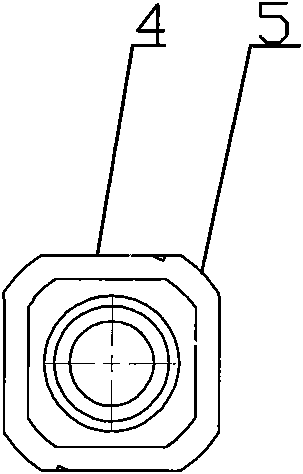

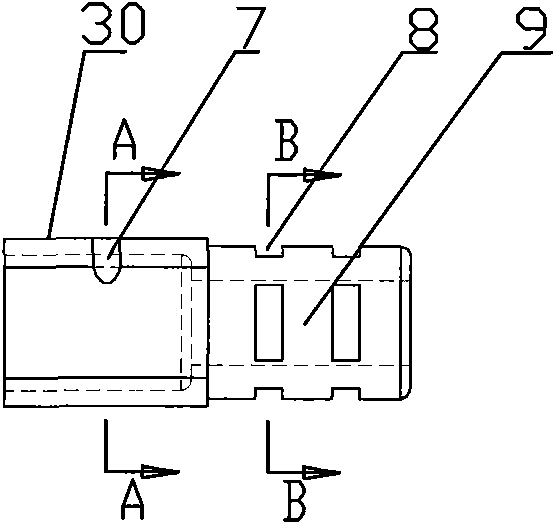

[0056] Embodiment one: if Figure 1 to Figure 7 As shown, the special-shaped multi-edge grooved drill rod of the present invention is composed of a hollow rod body 2, a convex connector 1 and a concave connector 3 connected to the two ends of the rod body 2 respectively, and the cross-sectional profile of the rod body 2 is composed of four straight lines arranged at intervals. Segment 4 and four arc line segments 5 are connected end to end. The shape of the rod body 2 is in the shape of four ribs. The surface of the rod body 2 is engraved with spiral grooves 6. A discontinuous spiral groove. The inner cavity of the rod body 2 is cylindrical and can also be designed to have the same contour as the outer surface. Both the male connector 1 and the female connector 3 are composed of left and right sections. The outer structures of the right segment 9 of the male connector and the left segment 10 of the female connector are the same as the internal cavity structure of the rod body...

Embodiment 2

[0057] Embodiment two: if Figure 8 ~ Figure 13 As shown, the difference from Embodiment 1 is that the female connector 3 has an integrated structure and its external structure is the same as that of the rod body. The rod body 2 is fixedly connected by means of friction welding.

Embodiment 3

[0058] Embodiment three: as Figure 14 ~ Figure 18 As shown, the difference from Embodiment 1 is that the male connector 1 is composed of three sections: left, middle and right, and the outer structure of the right segment 15 of the male connector is the same as that of the internal cavity of the rod body 2 and is inserted into the rod body 2 with an interference fit. , the external structure of the middle section 14 of the male connector is the same as that of the rod body 2, the left section 13 of the male connector is a conical external thread structure, and the inner cavity of the right section 21 of the female connector is screwed and matched with the left section 13 of the male connector. Conical internal thread structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com