Motor control method using space vector pulse width modulation and controller thereof

A technology of space vector pulse width and motor control, which is applied in the direction of vector control system, motor generator control, electromechanical brake control, etc. It can solve the problems of shortening vector time, increasing vector time, reducing the maximum speed and acceleration of the motor, etc., to achieve improvement Effect of effective vector time, maximum velocity and acceleration increase, decrease impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

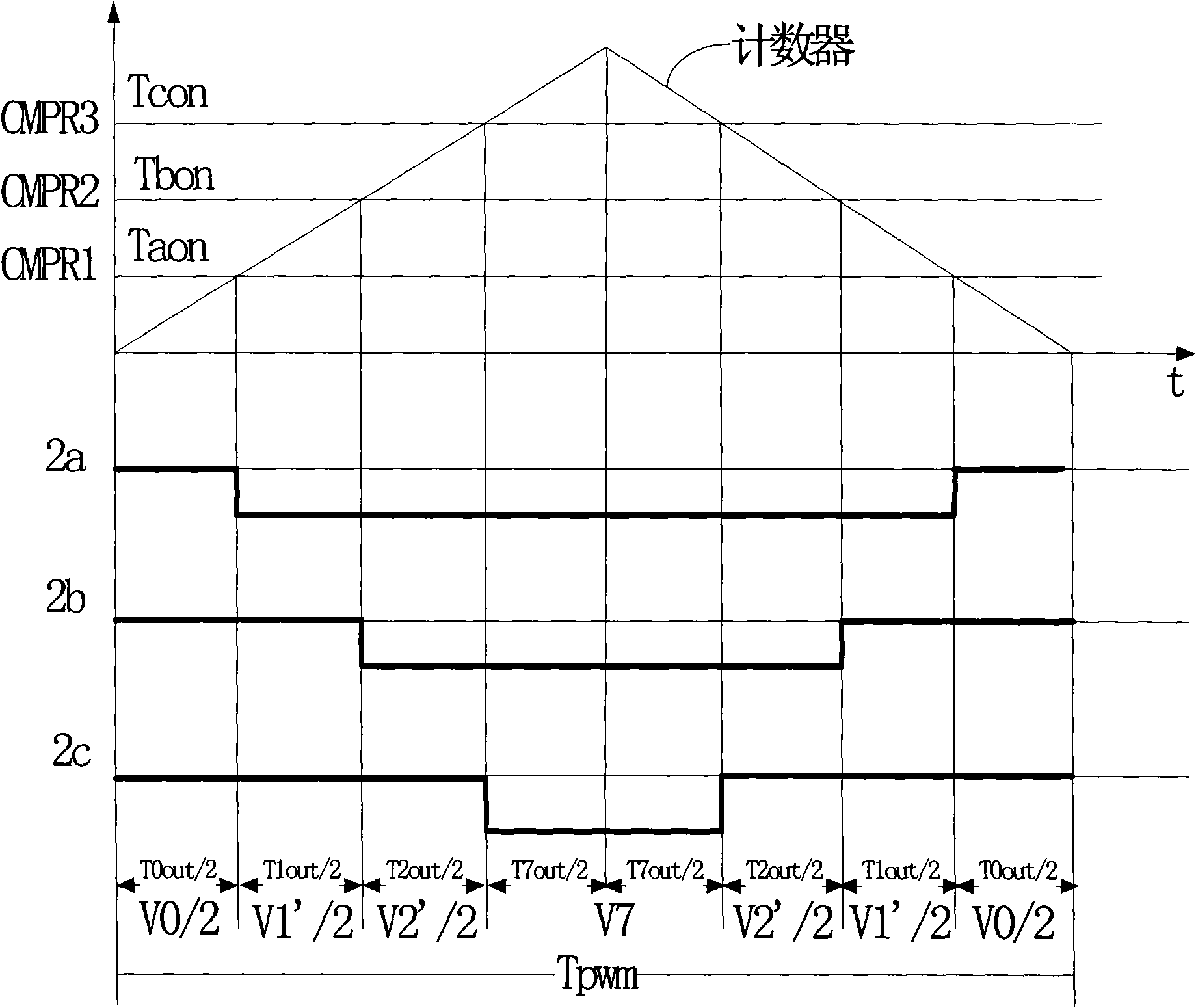

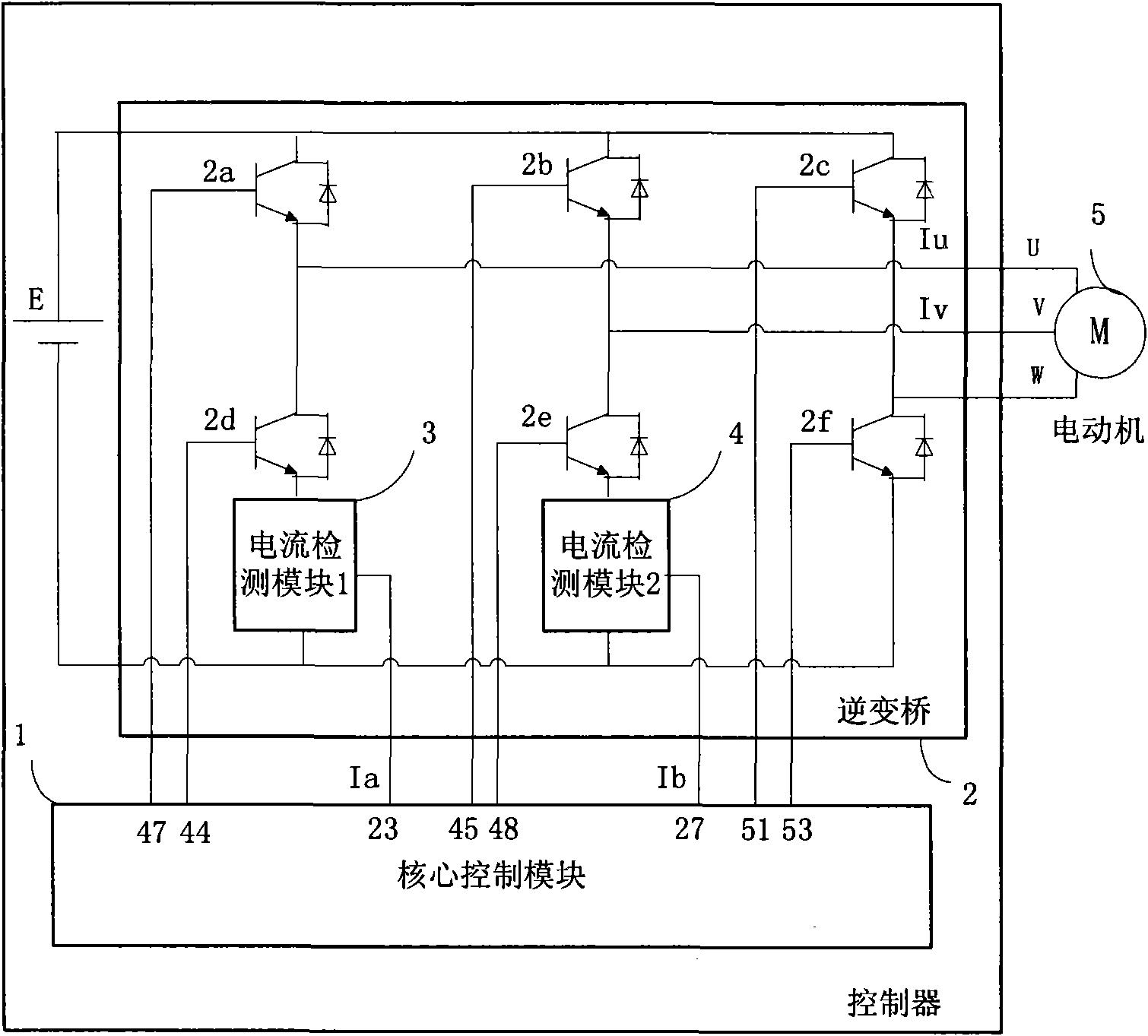

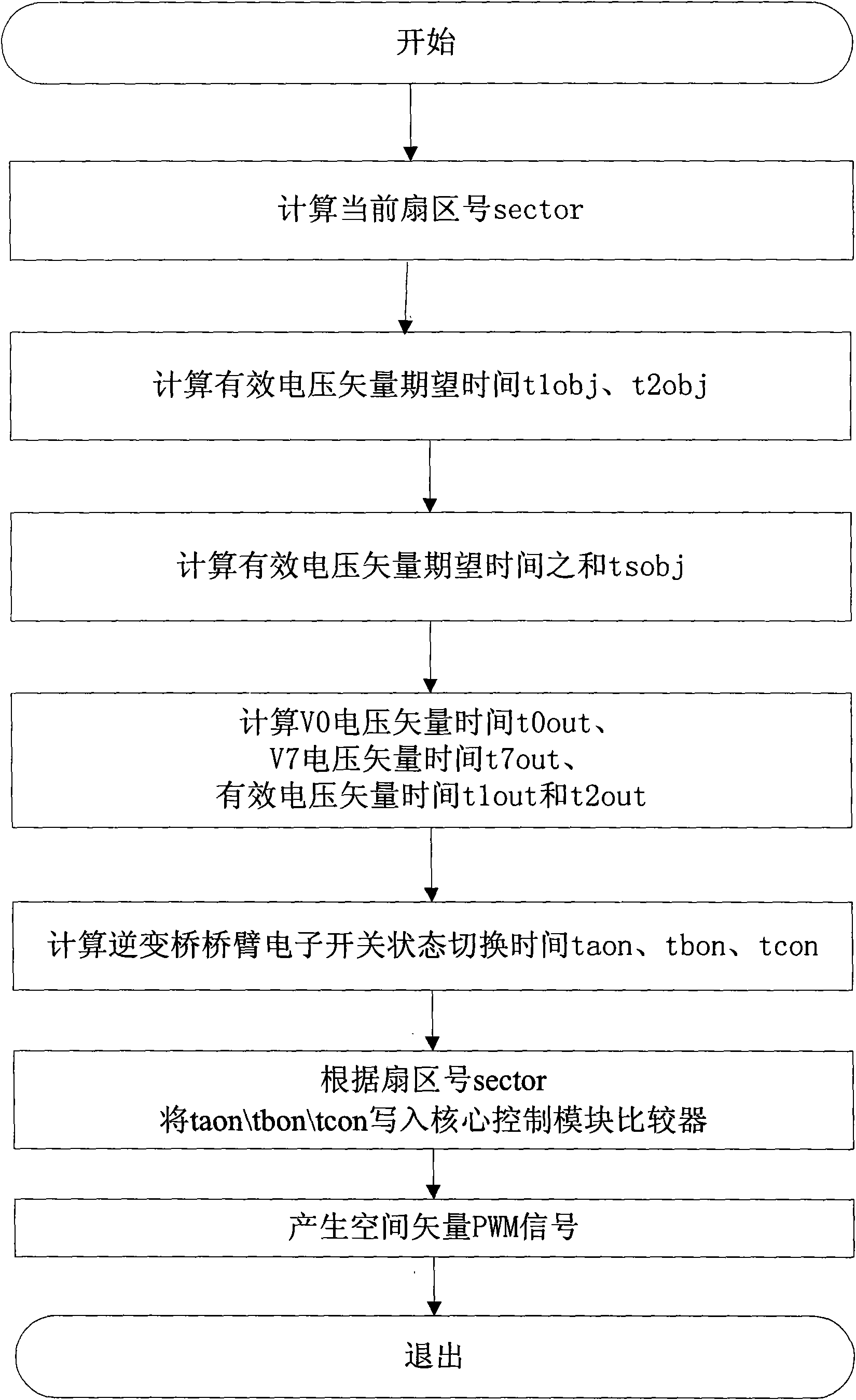

[0049] Such as figure 2 As shown, the present invention adopts the motor control method of space vector pulse width modulation, comprises core control module 1, the inverter bridge 2 that connects described core control module 1 and the motor 5 that connects inverter bridge 2, and this method comprises the following steps:

[0050] Step 1, current sampling step: when the inverter bridge 2 is in the V0 state, collect the output signals of the current detection modules 3 and 4 in the electronic switches 2d and 2e connected in series to the lower bridge arms of the inverter bridge 2, and output the current detection modules respectively 3 and 4 current signals Ia and Ib, the current signals Ia and Ib are proportional to the 5-phase current of the motor, and the acquisition time length is tad. The state of the switch is fully open;

[0051] Step 2, current control step: the core control module 1 receives the current signals Ia and Ib, transforms them through Clark and Park, comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com