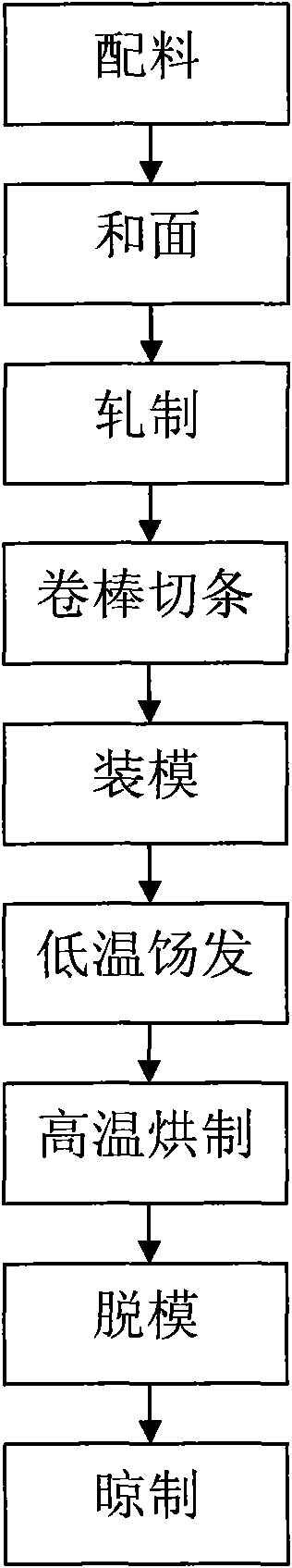

Production process of steamed bread slice proofing and baking flow line in steamed bread piece production

A production process and technology for steamed bread slices, which are used in baking, baked goods, dough fermenters, etc., and can solve the problems of large fluctuations in product output and quality, affected by seasons, and large floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Preparation of fabric

[0034] 11) Ingredients:

[0035] Prepared according to the following weight percentage raw materials:

[0036] Flour: 100 parts Peanut oil: 10 parts Sugar: 5 parts Milk: 5 parts Salt: 5 parts Water: Appropriate amount Yeast: 0.5 parts

[0037] Put the above mixture into the dough mixer and stir evenly to form a uniform dough; use the dough rolling machine to roll the dough into a strip shape with a thickness of about 2cm and a width of about 40cm;

[0038] 2) Mold loading; after mold loading, the fabric occupies 1 / 2 to 2 / 3 of the mold space,

[0039] 3) Proofing at low temperature;

[0040] The proofing temperature is controlled at 40 degrees, the humidity is 80%, and the proofing time is 25 minutes, and the fabric is fermented until it fills the mold space.

[0041] 4) high temperature baking;

[0042] Control the baking temperature at 200 degrees for 15 minutes. After baking, the outer surface of the steamed bread is slightly yellow. ...

Embodiment 2

[0045] 1) Preparation of fabric

[0046] 11) Ingredients:

[0047] Prepared according to the following weight percentage raw materials:

[0048] Flour: 100 parts Palm oil: 5 parts Sugar: 10 parts Milk: 10 parts Salt: 5 parts Water: Appropriate amount Yeast: 0.5 parts

[0049] Put the above mixture into the dough mixer and stir evenly to form a uniform dough; use a noodle rolling machine to roll the dough into a strip shape with a thickness of about 2cm and a width of about 40cm; roll a stick and cut it into strips;

[0050] 2) Mold loading; the fabric occupies 2 / 3 of the mold space,

[0051] 3) Proofing at low temperature;

[0052] The proofing temperature is controlled at 50 degrees, the humidity is 90%, and the proofing time is 15 minutes. The fabric ferments until it fills the mold space.

[0053] 4) high temperature baking;

[0054] Control the baking temperature at 220 degrees for 10 minutes. After baking, the outer surface of the steamed bread is slightly yellow. ...

Embodiment 3

[0057] 1) Preparation of fabric

[0058] 11) Ingredients:

[0059] Prepared according to the following weight percentage raw materials:

[0060] 100 parts of flour, sugar: 5 parts, 5 parts of milk, 5 parts of salt, water: appropriate amount, yeast: 2 parts

[0061] Put the above mixture into the dough mixer and stir evenly to form a uniform dough; use the noodle rolling machine to roll the dough into a strip shape with a thickness of about 2cm and a width of about 40cm; roll the stick and cut it into strips;

[0062] 2) Install the mold; after the mold is installed, the fabric occupies 3 / 5 of the mold space,

[0063] 3) Proofing at low temperature;

[0064] The proofing temperature is controlled at 60 degrees, the humidity is 90%, and the proofing time is 10 minutes.

[0065] 4) high temperature baking;

[0066] Control the baking temperature at 220 degrees for 8 minutes.

[0067] 5) demoulding and drying.

[0068] In summary, the method of the present invention uses he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com