Feeding device for horizontal planetary ball mill

A planetary ball mill and feeding device technology, applied in the direction of grain processing, etc., can solve the problems of difficult sealing technology, complex structure, etc., and achieve the effect of solving the problems of material leakage and dust, improving conveying efficiency, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described below in conjunction with the accompanying drawings.

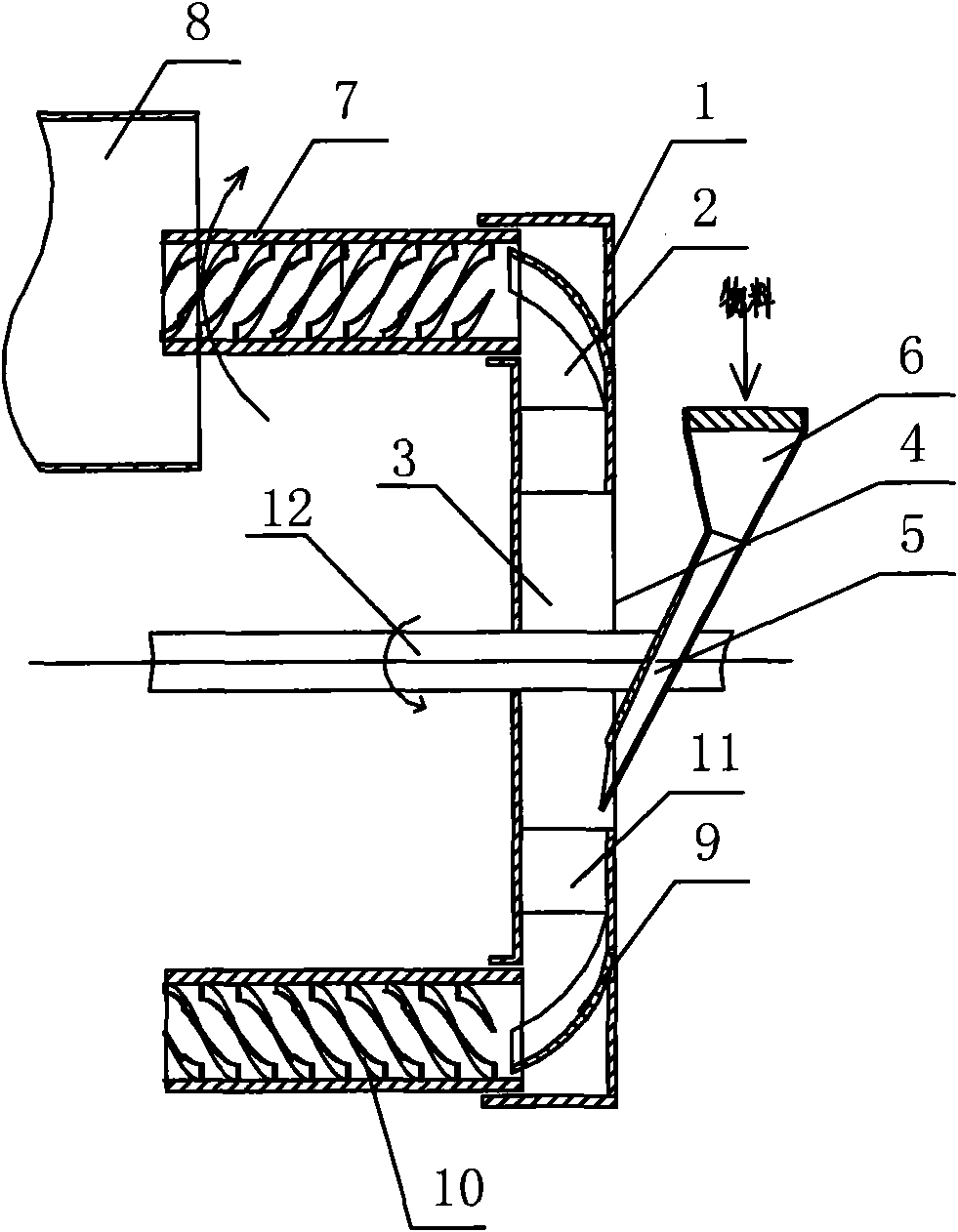

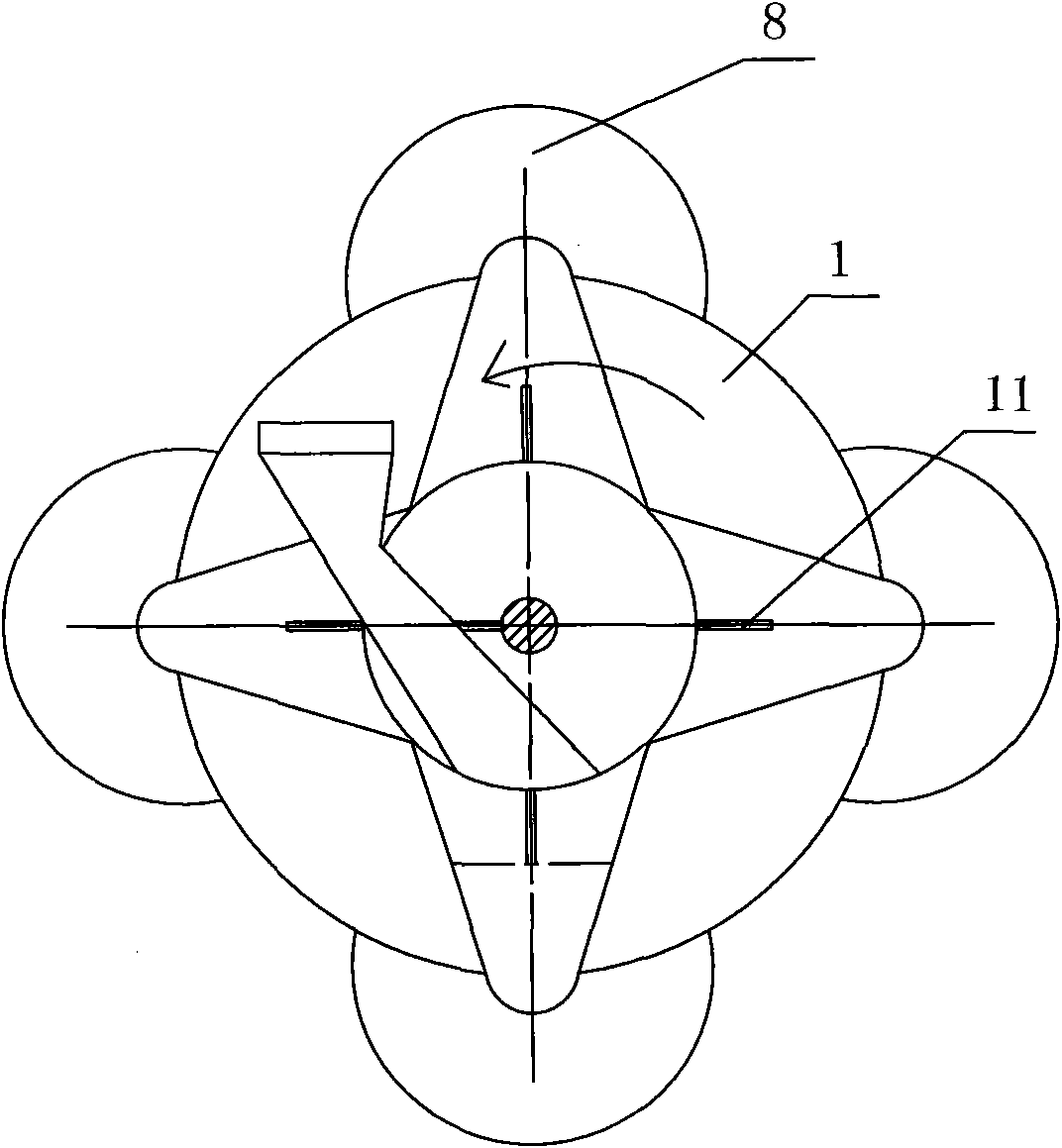

[0019] Such as figure 1 and figure 2 As shown, a feeding device of a horizontal planetary ball mill according to the present invention mainly includes a revolving disk 1, a feeding area 3, a circular opening 4 in the center of the revolving disk, a feeding pipeline 5, a material hopper 6, a hollow shaft 7. Arc-shaped chute 9, internal screw feeder 10 and large fan blade 11; where:

[0020] A feeding area 3 is provided at the center of the revolving disk 1 , and a circular opening 4 is provided on the outer wall of the revolving disk 1 corresponding to the feeding area 3 . The round opening 4 is provided with a feeding pipe 5 fixed on the frame and inserted obliquely at a certain angle, which is used to feed the material into the feeding area and the material channel in the revolution plate. The angle between the angle and the vertical direction is the smallest. Preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com