Processing method for chute in casing of hydraulic pump

A technology of hydraulic pump casing and processing method, which is applied in the field of hydraulic pumps and can solve the problems of expensive manufacturing of hydraulic pump casings and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

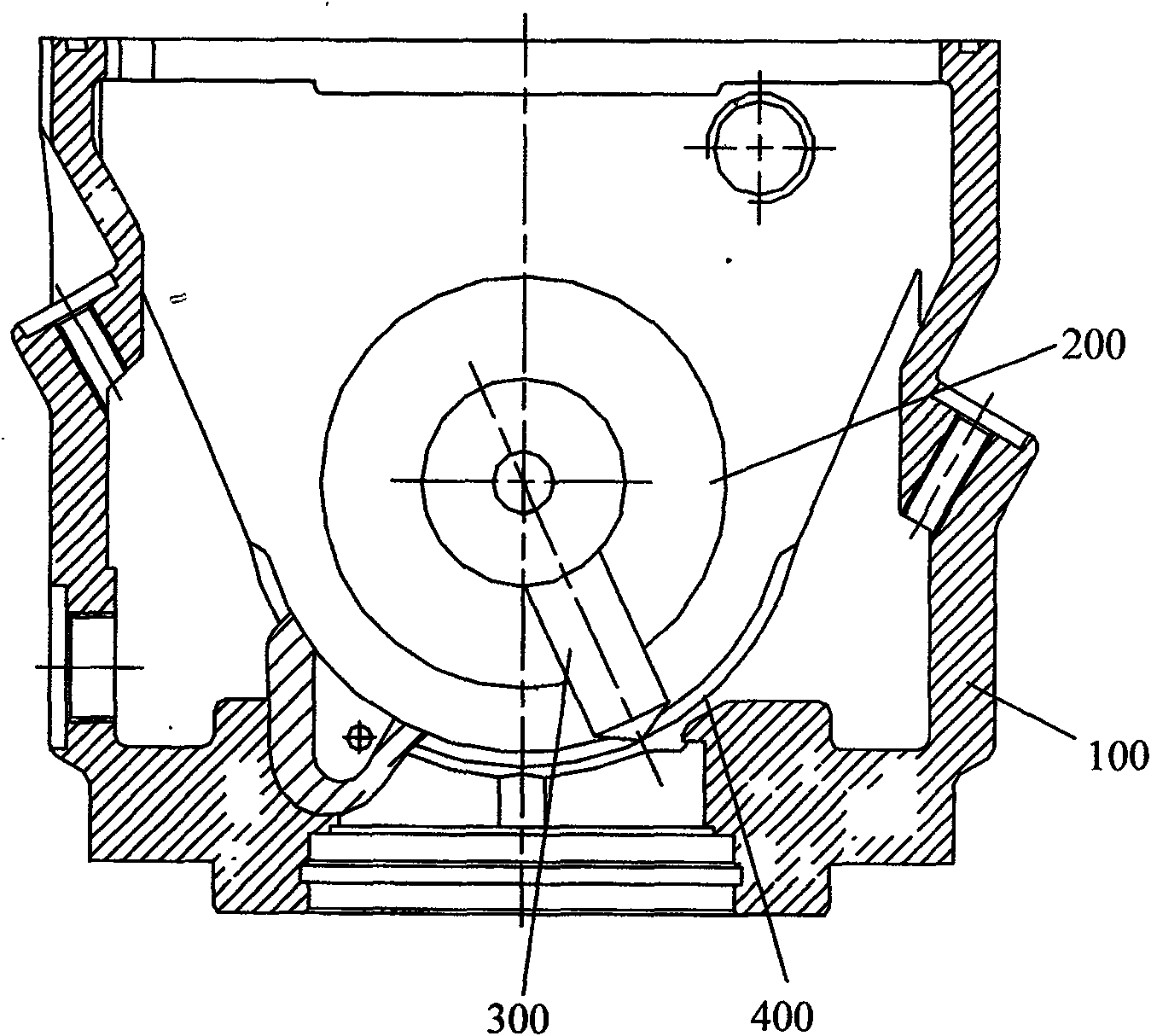

[0013] Such as figure 1 As shown, the processing method of the chute in the housing of the hydraulic pump of the present invention is to open a window 200 on both sides of the housing 100, and then insert the machining tool head 300 of an ordinary numerical control machine tool into the housing 100 from the window 200 on one side. Inside, the chute 400 is processed on the opposite side wall until the chute 400 is processed to meet the size requirements and precision requirements.

[0014] In the present invention, the two opened windows 200 are circular symmetrical windows, and the size of the windows 200 is such that the machining tool head 300 can penetrate into the housing 100 without affecting the strength of the housing 100 .

[0015] Ordinary CNC machine tools are ordinary horizontal CNC machining centers.

[0016] By opening the window 200 on the side of the housing 100, the processing cutter head of the ordinary CNC machine tool can be inserted into the inside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com