Plate spring type welding clamp

A technology of electric welding tongs and leaf springs, which is applied to the characteristics of welding rods, electrode support devices, etc., can solve problems such as hot handles, and achieve a reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

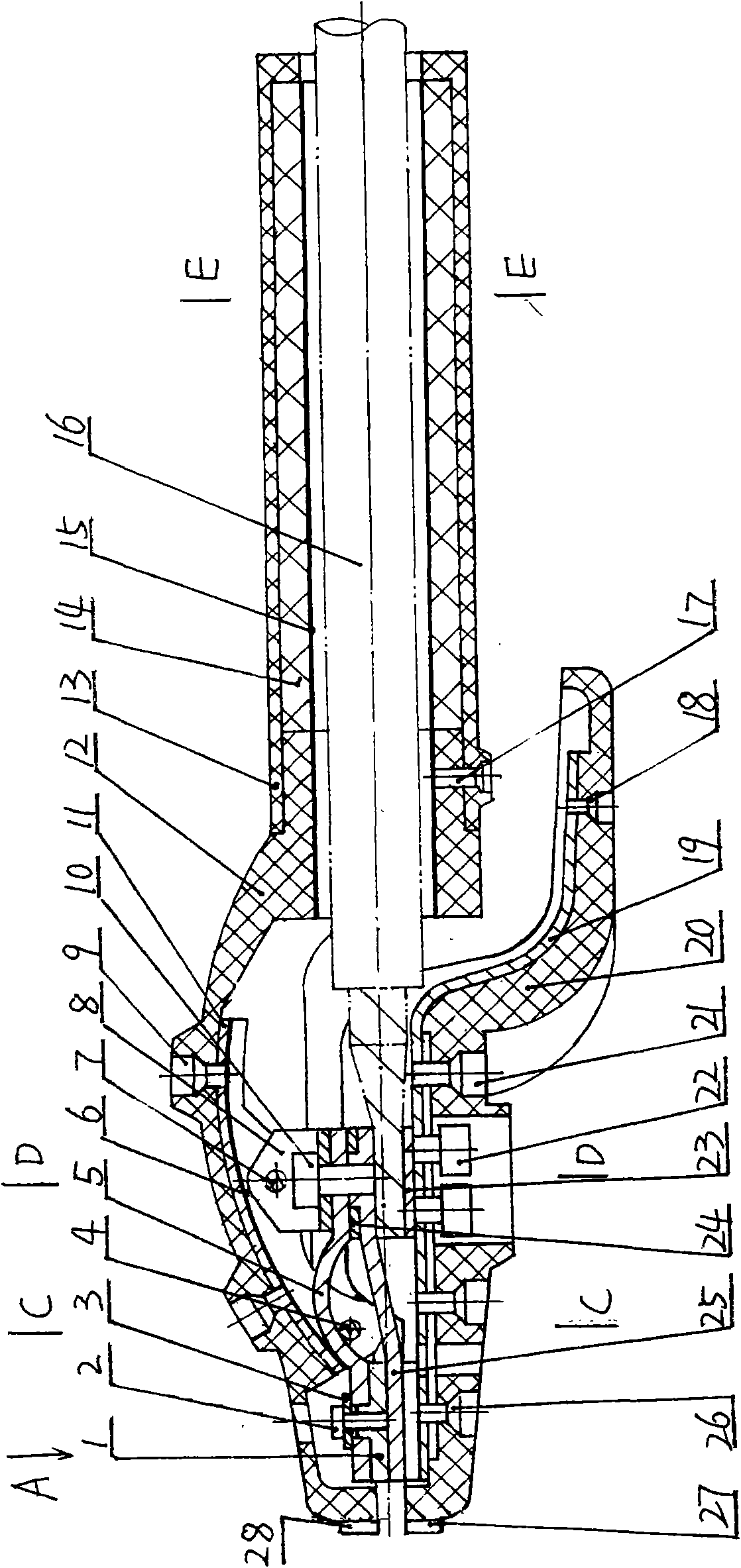

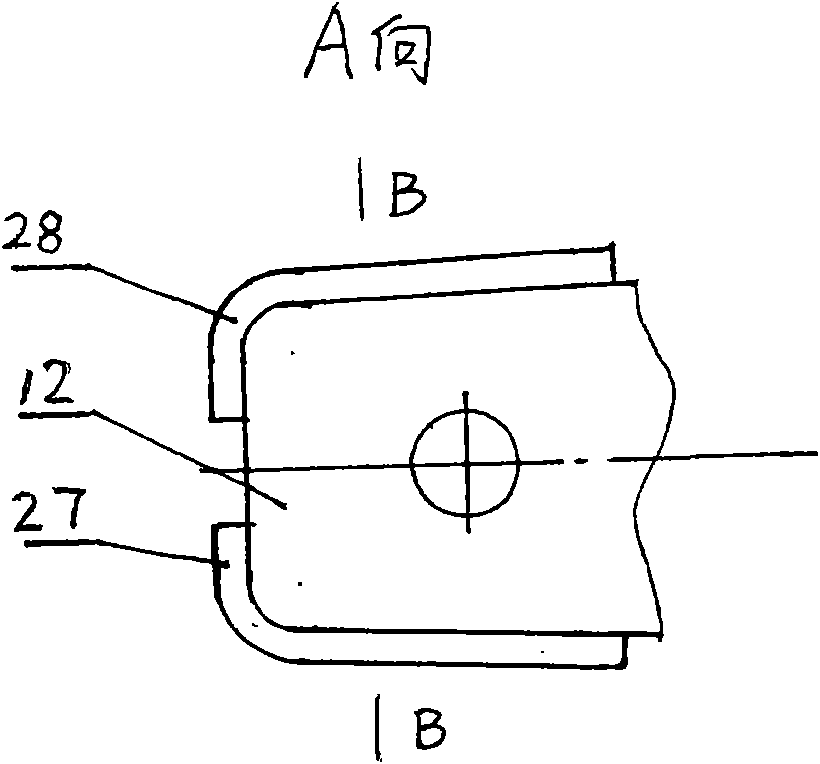

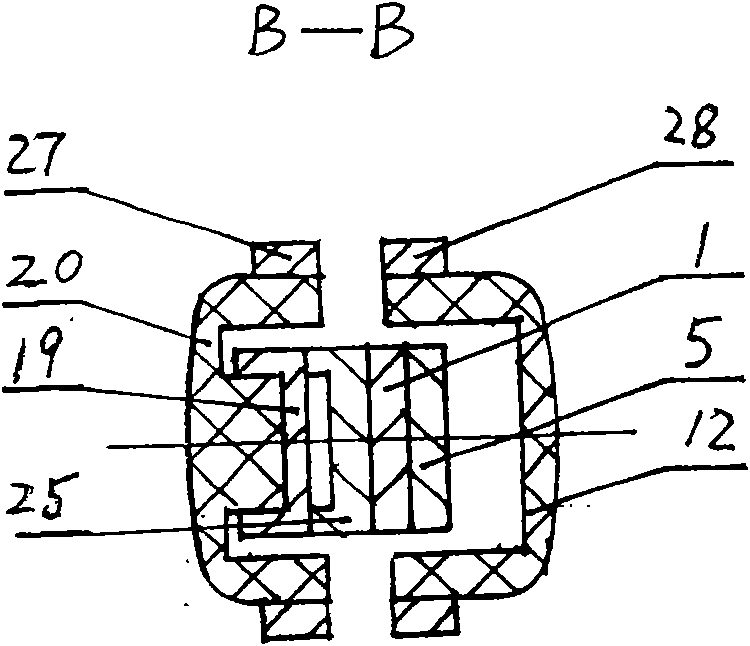

[0023] according to Figure 1-9 To describe the specific structure of the present invention in detail, the leaf spring electric welding tongs includes a handle assembly and a lower insulator assembly. The handle assembly includes handle insulator 13, heat insulation tube 14, aluminum foil heat-resistant reflective cylinder 15, upper insulator 12, coupling shaft 7, lifting spring shaft 4, lifting spring frame 11, aluminum foil heat-resistant reflective layer 6, screws 9, 17 , Upper temperature-resistant protective layer 28 and the like. The lower insulator assembly includes upper jaw 1, plate spring 5, support frame 8, cable 16, pressure plate 23, lower insulator 20, washer 3, screws 2, 26, 22, 21, 18, skeleton plate 19, connection frame 24 , the lower jaw 25, the lower temperature-resistant protective layer 27 and the like.

[0024] The inwall of the upper insulator 12 of the handle assembly utilizes screws 9 to fix the lifting spring frame 11 that the lifting spring shaft 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com