Method for lapping orifice silicon core capable of effectively improving contact area and reducing resistance

A contact area and silicon core technology, which is applied in chemical instruments and methods, silicon compounds, crystal growth, etc., can solve the problems of inability to locate in the left and right directions, poor quality of polysilicon, and high resistance at overlapping joints, so as to avoid lodging of silicon cores, The effect of improving quality and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The utility model can be explained in more detail with reference to the following examples, but the utility model is not limited to these examples.

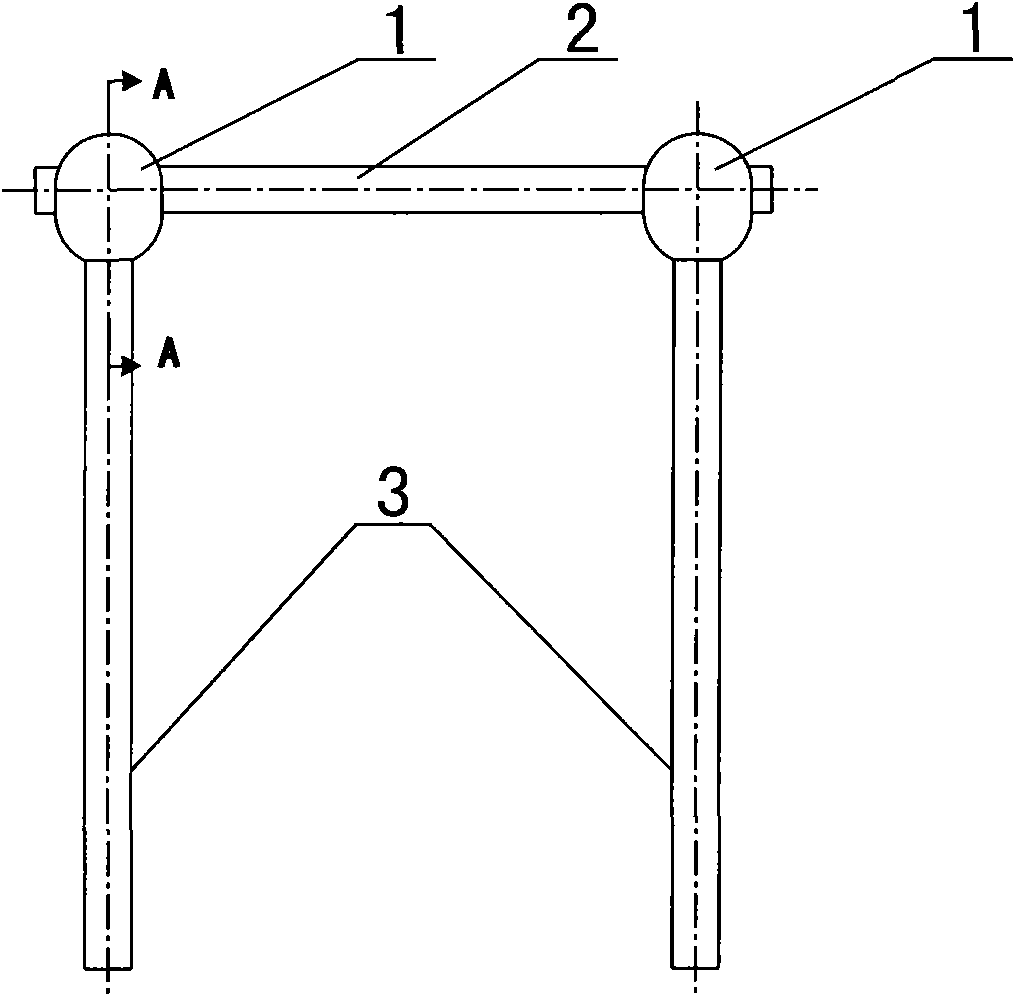

[0035] exist Figure 4 , 5 Middle; A hole-type silicon core overlapping method that can effectively improve the contact area and reduce the resistance, the concrete steps of the present invention are;

[0036] 1), first draw the horizontal silicon core 2 with silicon core spheres 1 at both ends of the required length;

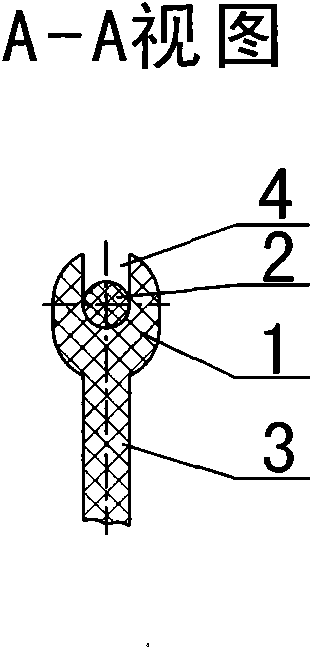

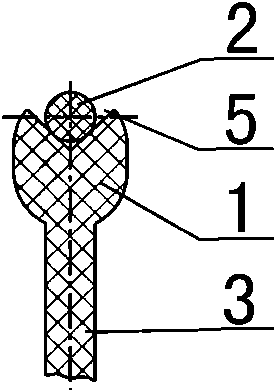

[0037] 2), drill a socket or a slot 6 on the silicon core sphere 1 at both ends of the horizontal silicon core 2;

[0038] 3), grinding the upper end of the vertical silicon core 3 into a shape that matches the hole or slot 6 drilled on the silicon core sphere 1;

[0039] 4), insert the upper end of the vertical silicon core 3 into the jack or slot 6 on the silicon core sphere 1 at both ends of the horizontal silicon core 2, and confirm whether it is firm. The jacks or slots 6 on the silicon core sphere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com