Multi-function sensor and heat current and temperature measuring method under high temperature

A sensor and multi-functional technology, which is applied in the field of simultaneous measurement of wall heat flow and temperature, can solve the problems of long response time, limited temperature range, and inability of thermocouples to achieve effective temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

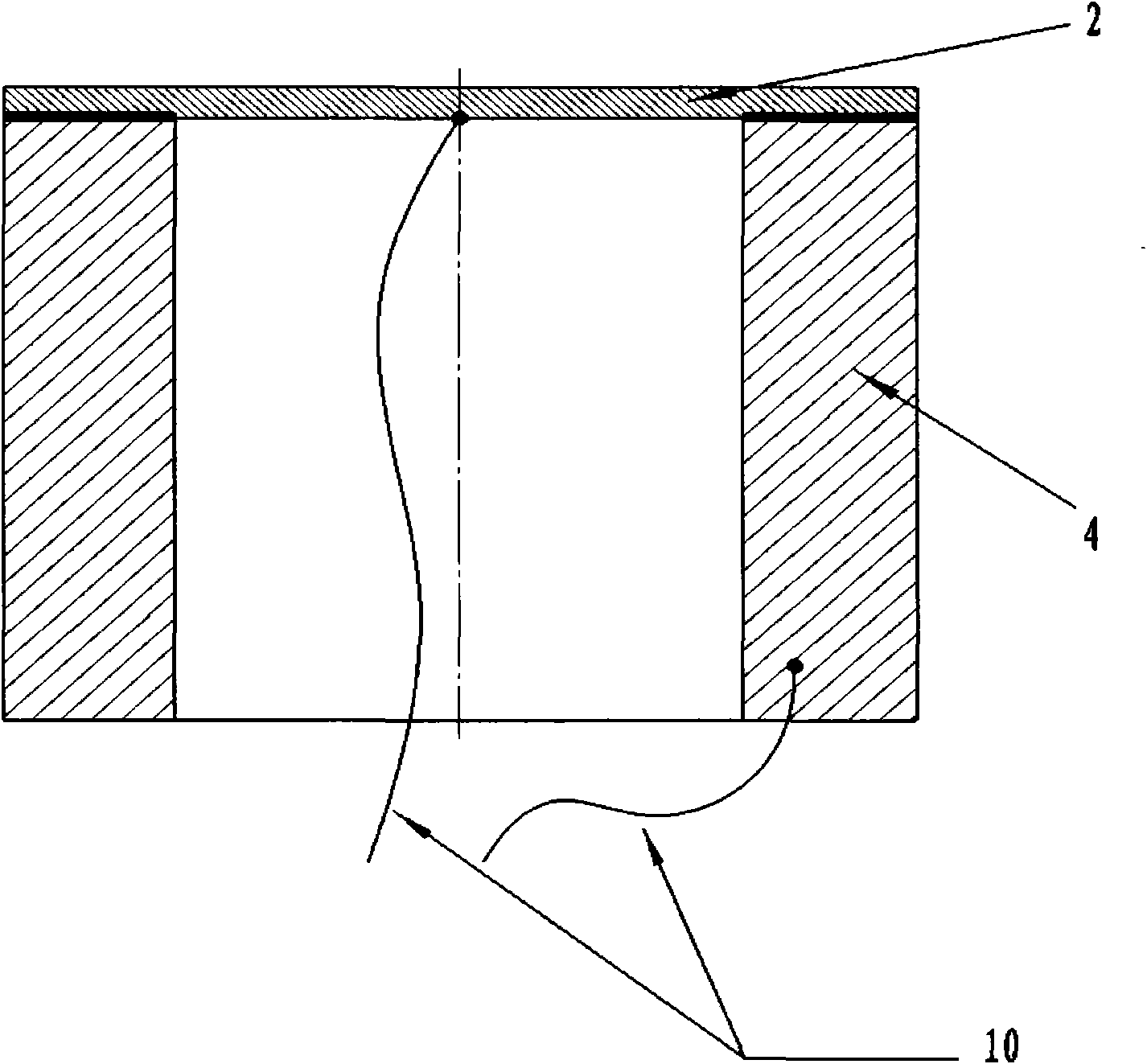

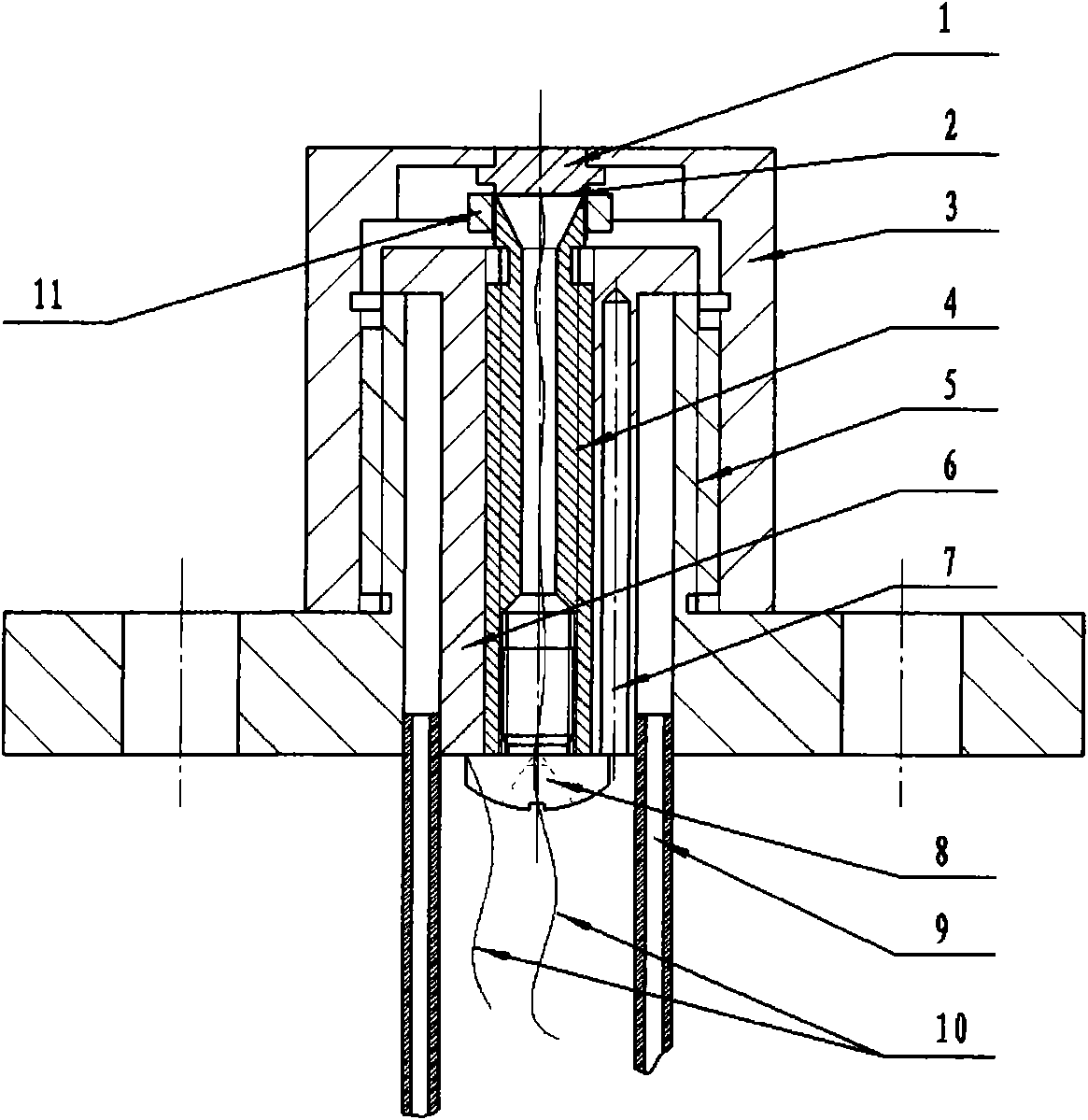

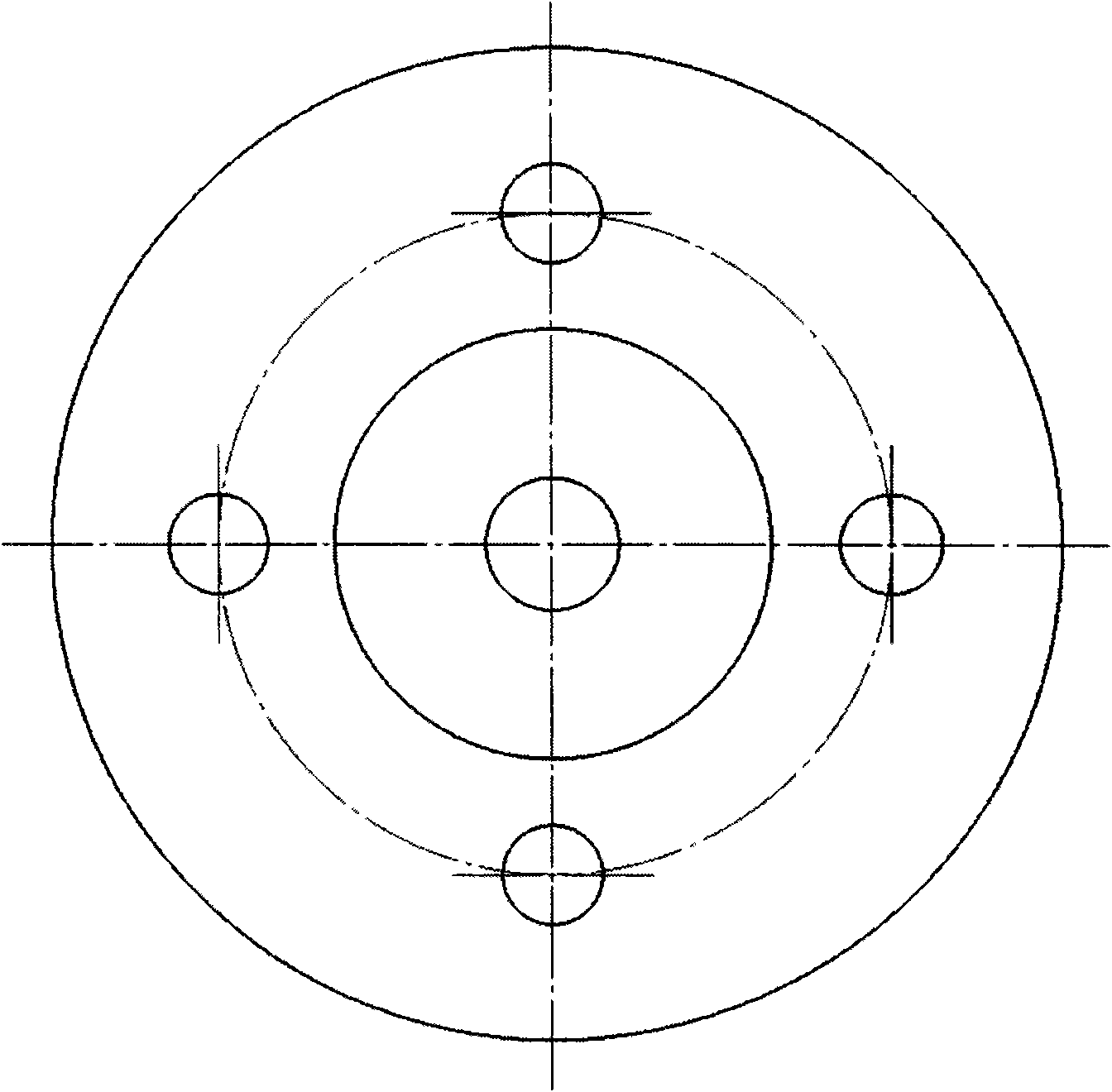

[0023] Such as figure 1 with 2 As shown, the multifunctional sensor of the present invention includes a stainless steel casing 3, on which a heat flow measuring head is arranged, and the heat flow measuring head includes a constantan sheet 2 arranged outside the stainless steel casing 3 and a copper heat sink arranged in the stainless steel casing 3 4, such as Figure 5a As shown, the constantan sheet 2 is pressed into a cap shape, fastened to the edge of the copper heat sink 4 and then tightened with a copper ring 11, and the following is obtained: Figure 5b In the shown heat flow measuring head, the constantan sheet 2 and the copper heat sink 4 are connected to form a copper-constantan thermocouple, and the center of the constantan sheet 2 is welded with a copper wire 10, and the copper wire 10 is guaranteed to be perpendicular to the constantan sheet 2, And it is in point contact with the center of the constantan sheet 2, the solder point is in good contact, and the stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com