Method for controlling result parameter of integrated circuit manufacturing procedure

A technology of result parameters and manufacturing procedures, applied in circuits, comprehensive factory control, comprehensive factory control, etc., can solve problems such as limited application range, and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

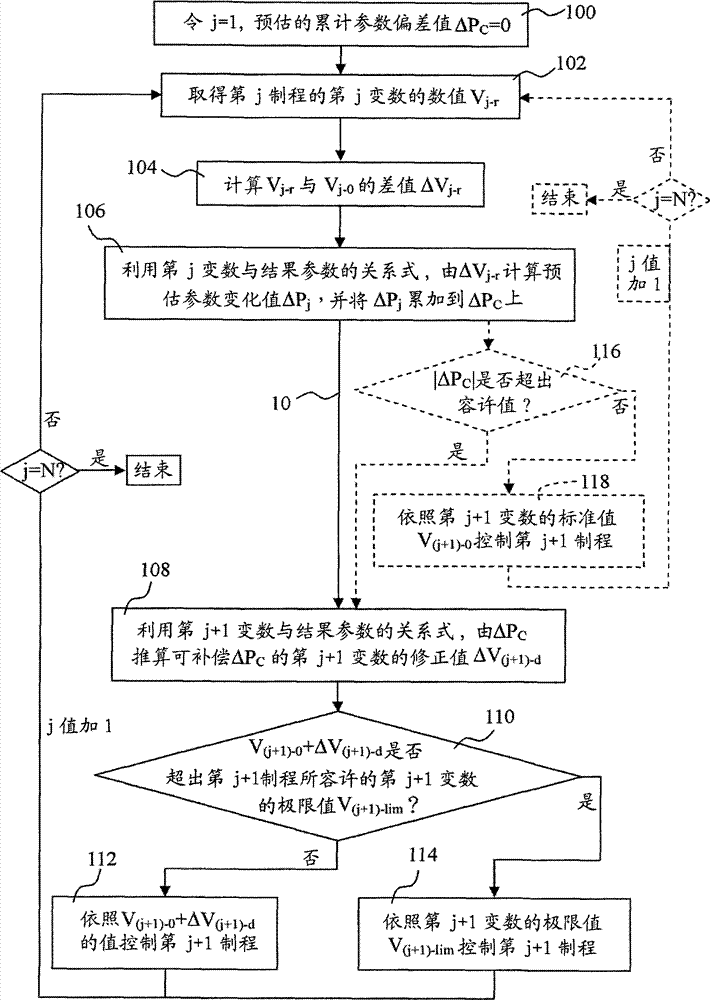

[0024] figure 1 A flowchart of a method for controlling result parameters of an integrated circuit manufacturing process according to an embodiment of the present invention is shown. In a practical example, the above-mentioned IC manufacturing process is a metal oxide semiconductor transistor (MOS transistor) manufacturing process, and the resulting parameter is the drain saturation current (Idsat) or the threshold voltage of the MOS transistor.

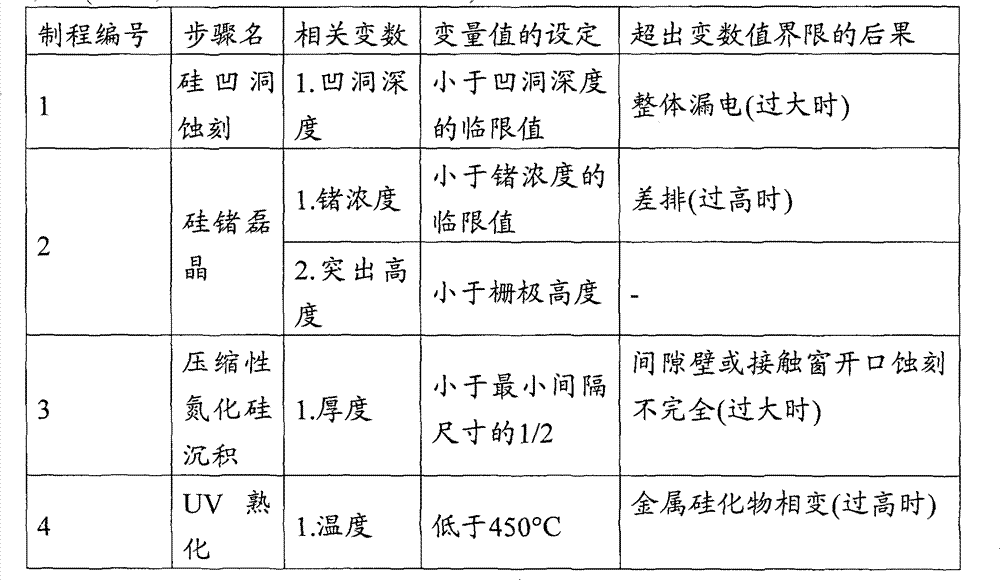

[0025] The IC manufacturing process includes processes 1-N related to the result parameter, before, after and / or in the middle of which other processes irrelevant or lowly related to the result parameter may be inserted. The i-th process in the process 1-N includes at least one i-th variable related to the result parameter; for example, the first process includes a first variable V related to the result parameter 1 , the 2nd process includes 2 2nd variables V related to the result parameters 2(1) with V 2(2) etc. Therefore, the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com