Method for identifying blockages in sprinkler devices and apparatus for carrying out this method

A technology of equipment and nozzles, which is applied in the field of devices implementing the method, can solve problems such as component failure, and achieve the effects of reducing risks, avoiding machine shutdown, and eliminating manual adjustment work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

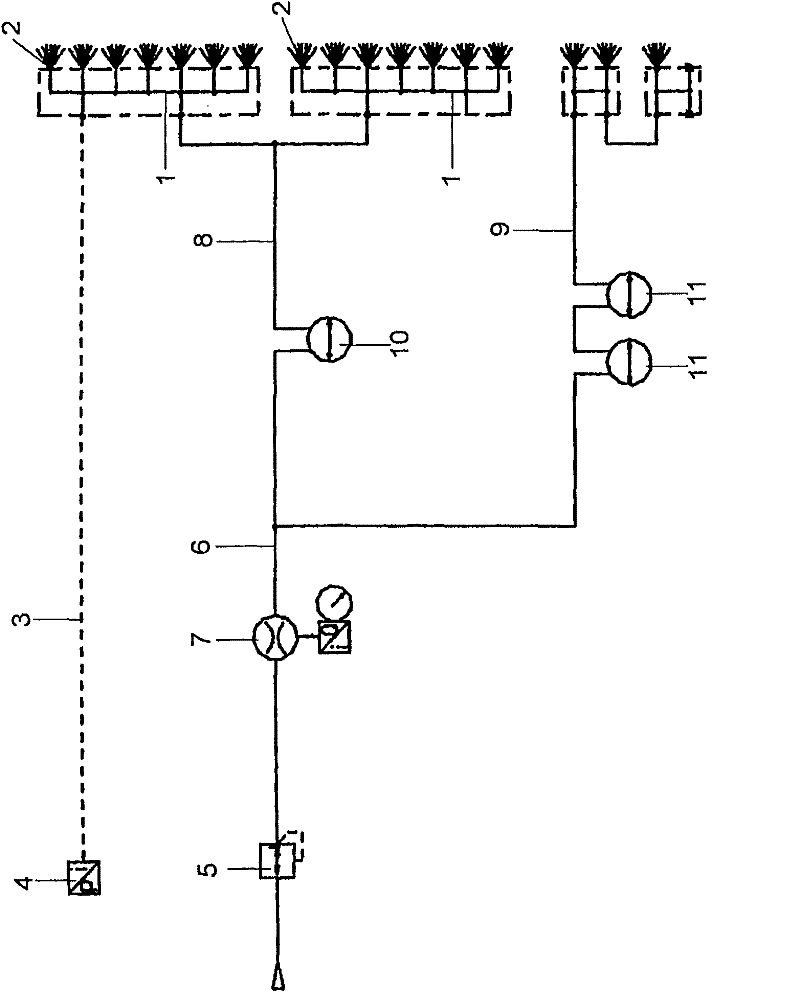

[0016] exist figure 1 A nozzle assembly for the spraying of the cutting drum is schematically shown at 1 in FIG. 2 , wherein a single nozzle is indicated with reference number 2 . The pressure in the supply line of this nozzle is detected via the control line 3 and the pressure sensor 4 . The medium is supplied to the nozzle assembly 1 and the nozzle 2 through a pressure reducing valve 5 and a pipeline 6 , and a flow sensor 7 is connected to the pipeline 6 . Now, however, the medium is not only supplied via the line 8 to the nozzle assembly 1, but also via the line 9 to the nozzles of the charging table in order to spray and cool the particles in this way. The electric motor to be controlled, in particular the cutting motor, is shown schematically with the reference numeral 10 , and the two loading motors are indicated with the reference numeral 11 . The cutting motor or the loading motor can be directly influenced by evaluating the values of the flow sensor and the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com