Device and method for positioning fixed scroll

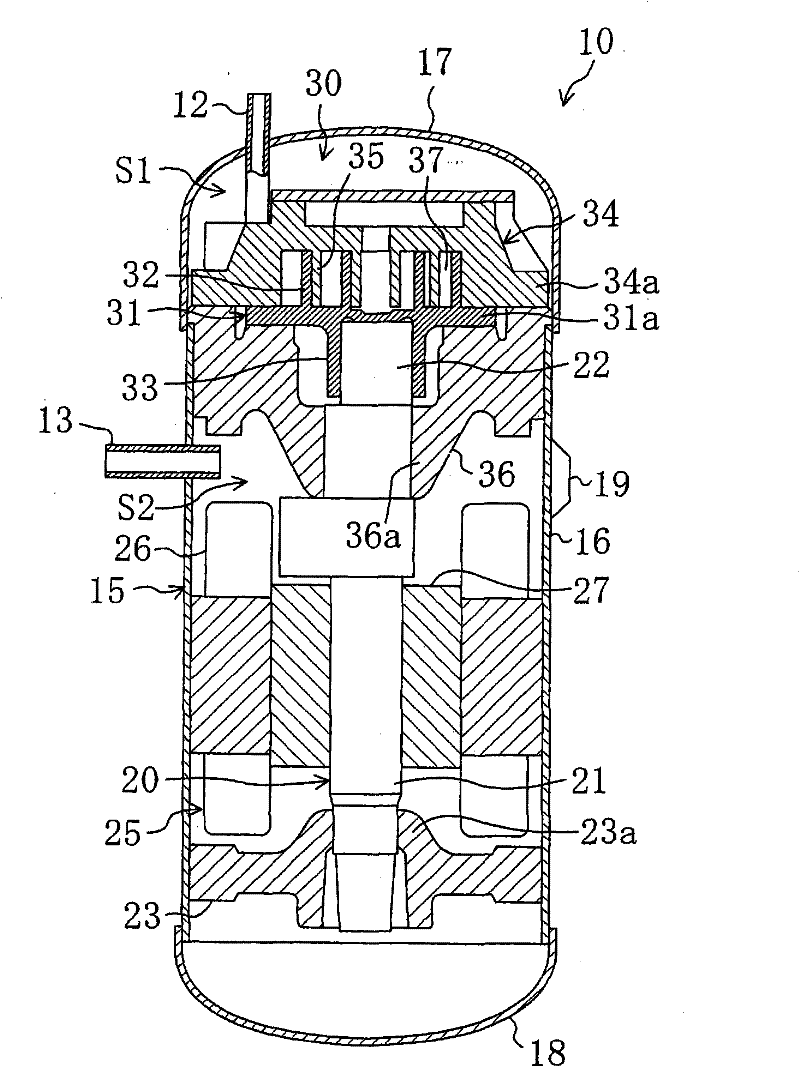

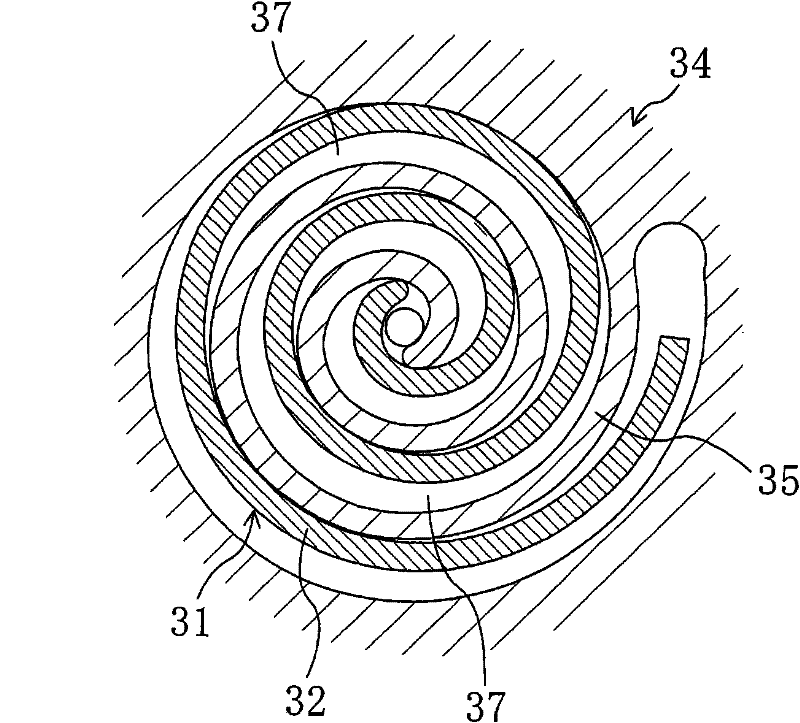

A technology of stationary scroll and positioning device, which is applied to the combination of elastic fluid rotary piston type/oscillating piston type pump, rotary piston type pump, rotary piston type machinery, etc., to prevent rotation and improve positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

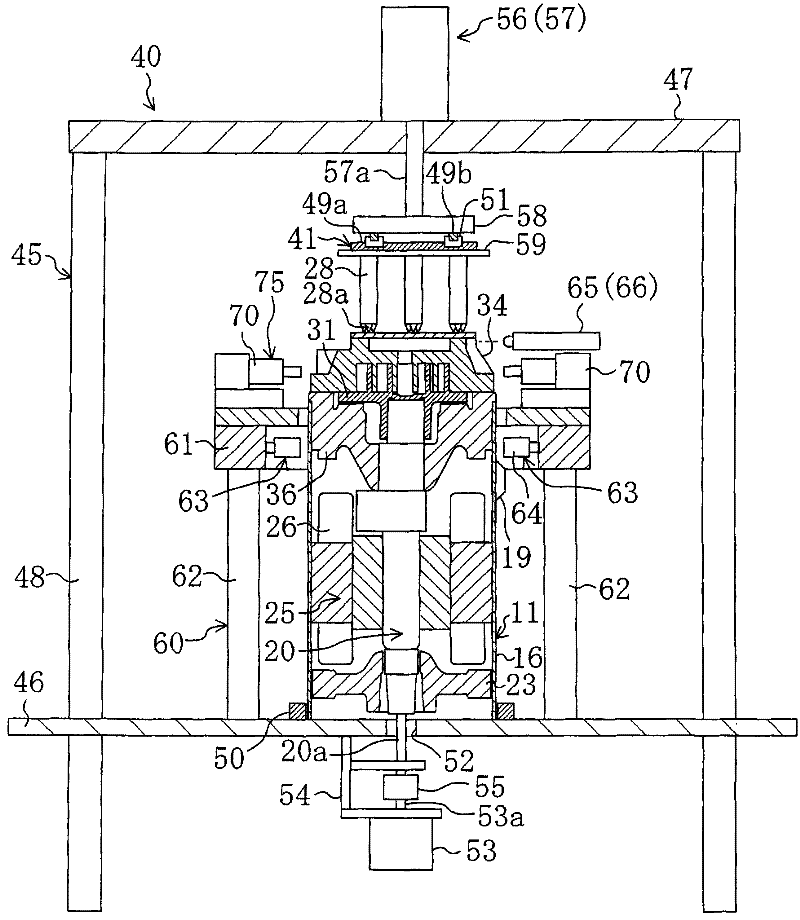

[0189] The following configurations can also be adopted in each of the above-described embodiments.

[0190] For example, in the above-described embodiment, the air cylinder unit 100 is used to advance and retreat the head portion 74 of the striking unit 70 . However, the cylinder part 100 can also be replaced by a clamping mechanism, a cam mechanism, etc.; the part that moves the fixed scroll 34, that is, the striking assembly 70 is not necessarily a structure that uses the piezoelectric element 73, and other structures can also be used, such as A moving mechanism 75 and the like of a ball screw type feeding mechanism are used. In short, as long as the moving mechanism 75 can adjust the position of the fixed scroll 34 , its structure can be appropriately changed.

[0191] In the above-described embodiment, the fixed scroll 34 is positioned while the movable scroll 31 is rotated, but it is also possible to stop the movable scroll 31 at a predetermined position and hit the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com