Machine for freezing cane juice

A technology of sugarcane juice and electric motor, which is applied in refrigerators, compressors, juice extraction, etc., can solve the problems of difficult roll cleaning, reduce the original flavor and concentration of sugarcane juice, and achieve no dead ends, less chance of pollution, clean and thorough The effect of dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

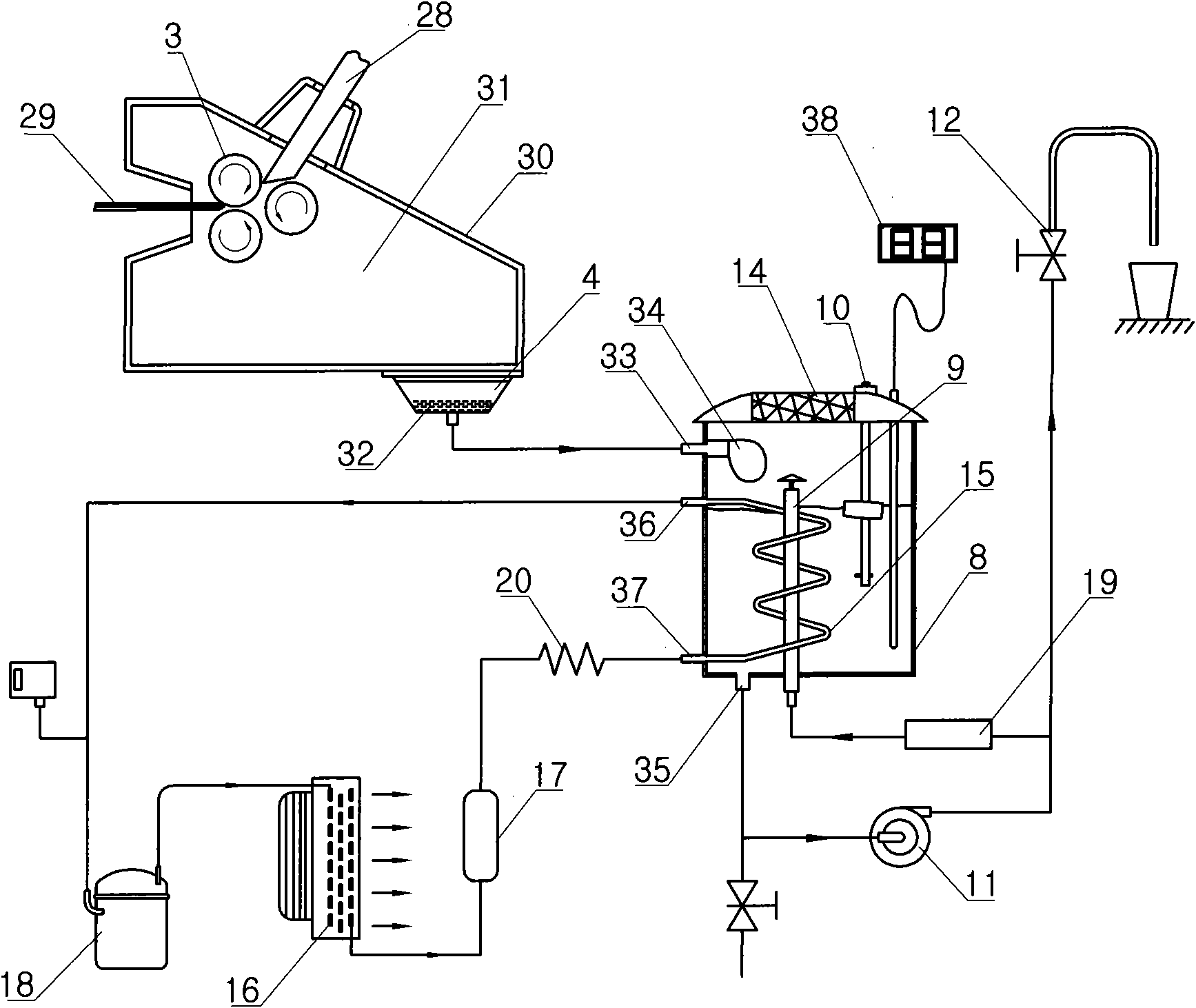

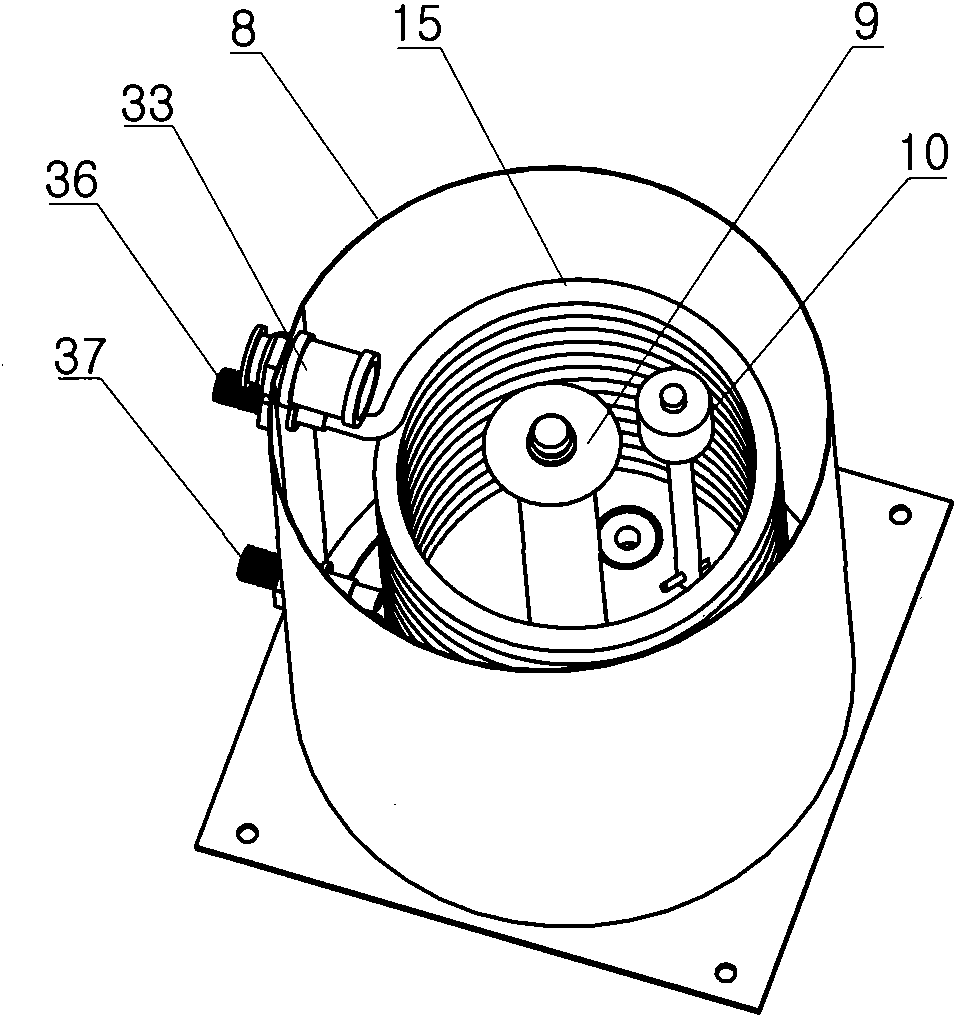

[0020] The refrigeration device of embodiment 1 comprises evaporation coil 15, condenser 16, drier filter 17, capillary 20 and compressor 18; Condenser 16, dry filter 17, capillary tube 20 are connected to the inlet 37 of evaporation coil 15, and outlet 36 of evaporation coil 15 is connected to the low-pressure port of compressor 18; The heat of the juice cools the cane juice. Cane juice storage tank 8 is also equipped with temperature sensor 38 and is used for controlling the start and stop of compressor 18.

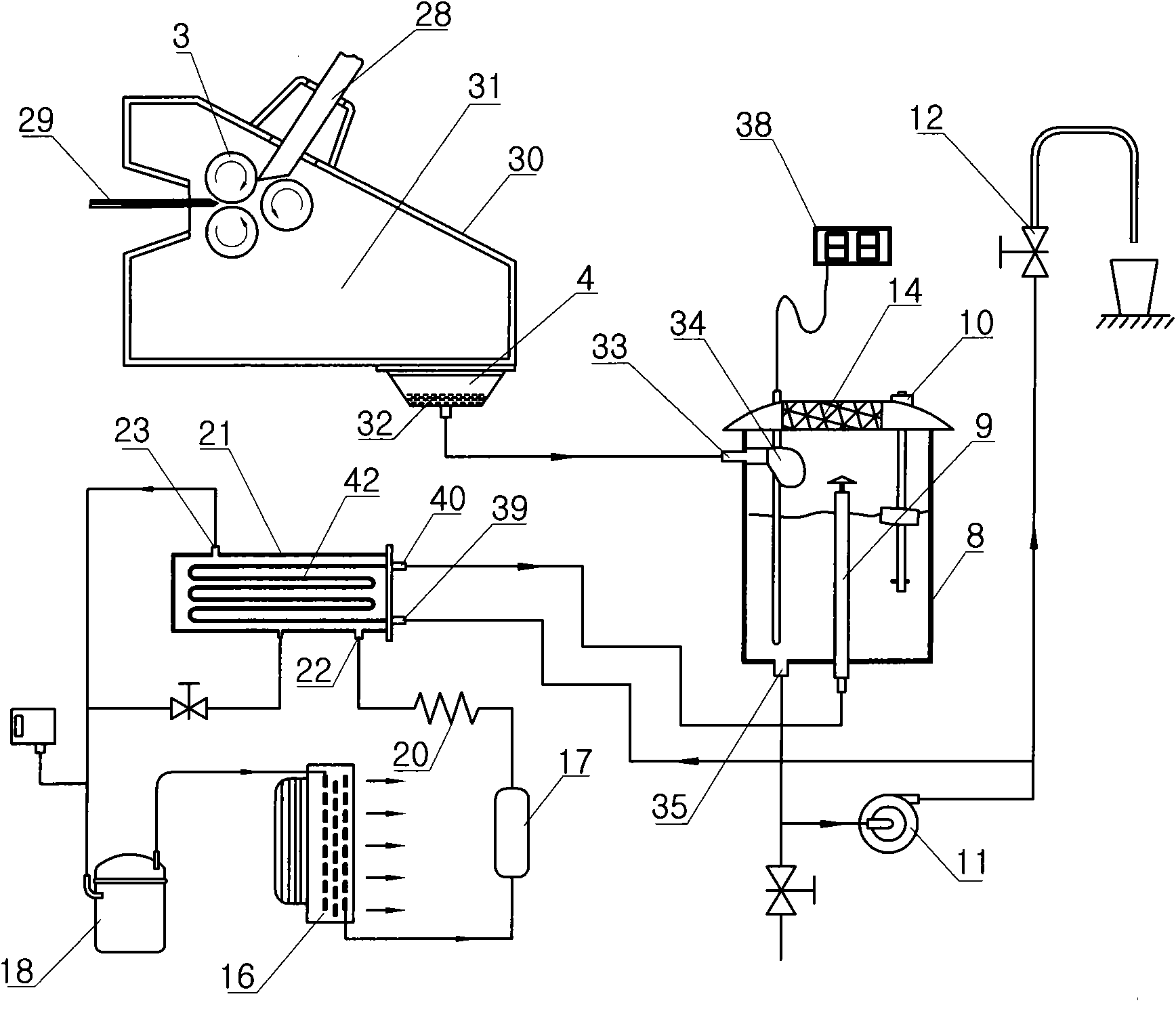

[0021] see image 3 , the sugarcane juice circulation device of embodiment 2 has cane juice storage tank 8, fountain 9, liquid level switch 10, water pump 11 and gooseneck faucet 12 equally; Liquid level switch 10 and fountain 9 are installed in the sugarcane juice storage tank 8 , the liquid inlet 33 of the sugarcane juice storage tank 8 is connected to the sugarcane juice collecting tray 4, the low pressure side of the water pump 11 is connected to the liquid outlet...

Embodiment 2

[0022] The main difference between Embodiment 2 and Embodiment 1 is that it uses a shell-and-tube evaporator 21 to replace the evaporation coil 15 of Embodiment 1. see Figure 4 and Figure 5 The shell and tube evaporator 21 has an outer cylinder 41, a heat exchange tube 42, a left end plate 43, a right end plate 44, a left sealing gasket 45, a right sealing gasket 46, a left end cover 47, a right end cover 48, a water inlet 39, an outlet The water port 40, the refrigerant inlet 22 and the refrigerant outlet 23; the water inlet 39 and the water outlet 40 are all arranged on the left end cover 47, and the water barriers 49 in the left end cover 47 and the right end cover 48 separate the 24 heat exchange tubes 42 into Two groups, sugarcane juice enters from the water inlet 39, reaches the right end cover 48 through 12 heat exchange tubes 42, and then reverses and flows from the other 12 heat exchange tubes 42 to the water outlet 40; the refrigerant flows outside the 24 heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com