High dielectric constant silastic used for electric stress control and preparation method and application thereof

A high dielectric constant, silicone rubber technology, applied in rubber insulators, organic insulators, etc., can solve the problems of flame-retardant silicone rubber wires and cables containing halogens, environmental protection, physical and mechanical performance degradation, and higher electrical conductivity, etc., to improve the electric field distribution , excellent mechanical properties and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

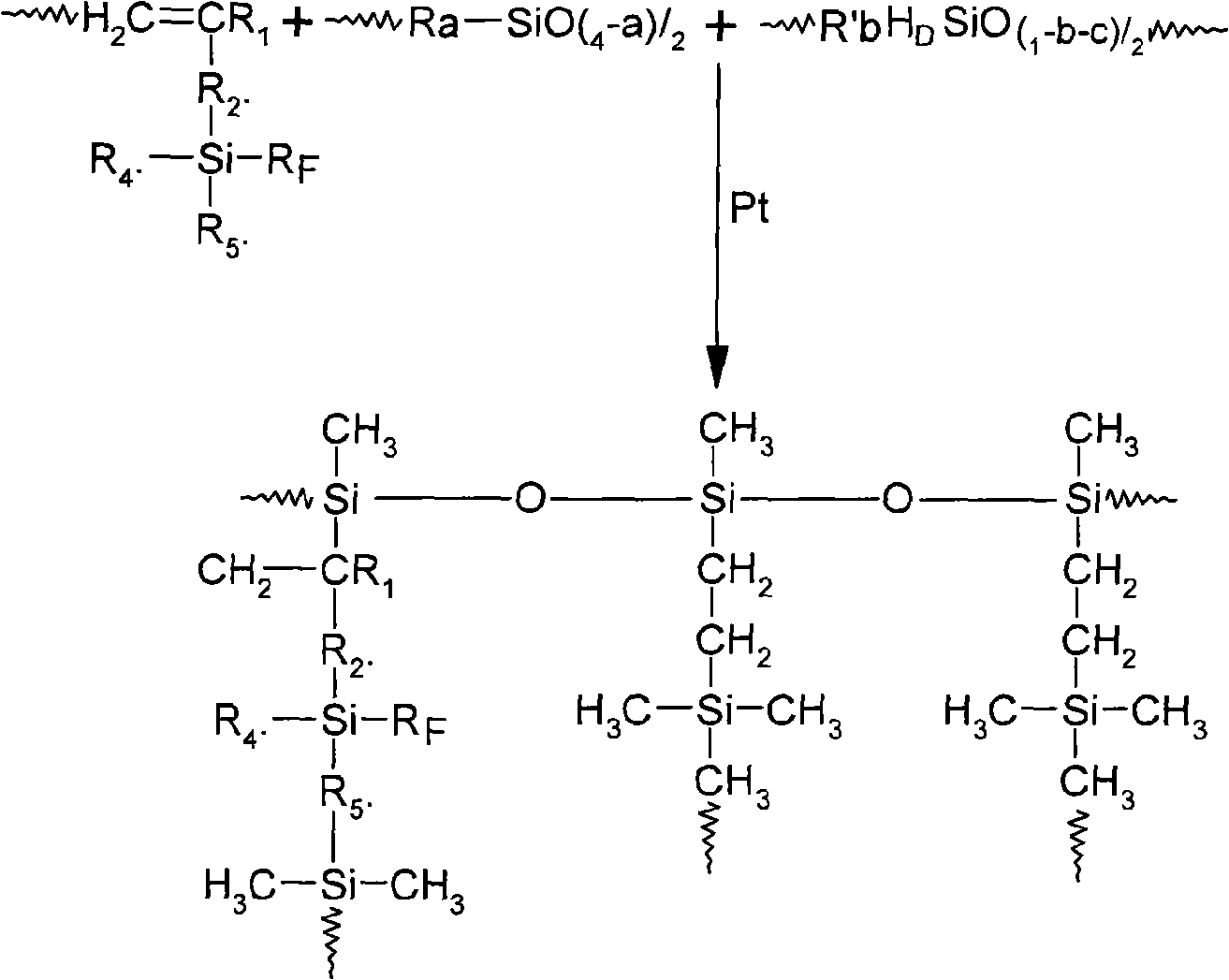

Method used

Image

Examples

Embodiment 1

[0039] Contains 45 parts of silicon dioxide, 40 parts of acetylene carbon black, B a TiO 3 80 parts of 17 parts of base rubber, 40 parts of organopolysiloxane, 6 parts of organohydrogen polysiloxane, 0.8 parts of fluorosilicon multipolymer, 0.2 parts of plasticizer, Pt-Cat. (platinum chromium compound) 0.1 parts by weight, 0.3 parts by weight of pigment, uniformly mixed by kneading, the speed ratio of the roller is 3.0; the distance between the rollers is 4mm, water cooling is adopted, and the temperature is controlled at 40°C. Then, the conventional thermal vulcanization extrusion molding method is used to obtain the silicone rubber tube of the present invention at a vulcanization traction temperature of 260 ° C, a rapid vulcanization setting channel temperature of 680 ° C, and an extrusion speed of 60 rpm. Test its comprehensive physical properties: hardness, Shore A: 41; tensile strength, Mpa: 5.7; tear strength, KN / m: 33; elongation at break, %: 560; volume resistivity, ...

Embodiment 2

[0041] Contains 40 parts of silicon dioxide, 25 parts of acetylene carbon black and B a TiO 3 10 parts of 20 parts of base rubber, 40 parts of organopolysiloxane, 1 part of organohydrogen polysiloxane, 2 parts of fluorosilicone multipolymer, 0.2 parts by weight of plasticizer, 0.2 parts by weight of polymerization inhibitor, Pt- Cat. (platinum chromium compound) 0.1 weight part, pigment 0.2 weight part, uniformly mixed by kneading, the speed ratio of the roller is 2.0; the distance between the rollers is 5mm, water cooling is adopted, and the temperature is controlled at 35°C. Then use the conventional thermal vulcanization extrusion molding method to obtain the product of the present invention at a vulcanization traction temperature of 250° C., a rapid vulcanization setting channel temperature of 700° C., and an extrusion speed of 50 rpm. Test its comprehensive physical properties: hardness, Shore A: 34; tensile strength, Mpa: 5.7; tear strength, KN / m: 34; elongation at bre...

Embodiment 3

[0043] Contains 30 parts of silicon dioxide, 30 parts of acetylene carbon black and B a TiO 3 40 parts of 15 parts of base rubber, 60 parts of organopolysiloxane, 3.5 parts of organohydrogen polysiloxane, 1.5 parts of fluorosilicone multipolymer, 0.2 parts by weight of plasticizer, 0.2 parts by weight of polymerization inhibitor, Pt- Cat. (platinum chromium compound) 0.1 weight part, pigment 0.1 weight part, uniformly mixed by kneading, the speed ratio of the roller is 2.0; the distance between the rollers is 3mm, water cooling is adopted, and the temperature is controlled at 25°C. Then use the conventional thermal vulcanization extrusion molding method to obtain the product of the present invention at a vulcanization traction temperature of 240° C., a rapid vulcanization setting channel temperature of 300° C., and an extrusion speed of 20 rpm. Test its comprehensive physical properties: hardness, Shore A: 34; tensile strength, Mpa: 5.7; tear strength, KN / m: 34; elongation a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com