Experimental method and device for simulating exploitation of gas hydrates

An experimental method and hydrate technology, which is applied in the fields of fluid mining, mineral mining, earth square drilling, etc., can solve the problems of lack of experimental simulation means and the inability to simulate the environment of hydrate formation, and achieve the effect of optimizing gas production rate and energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Example 1: Experimental Simulation of Methane Hydrate Depressurization Exploitation

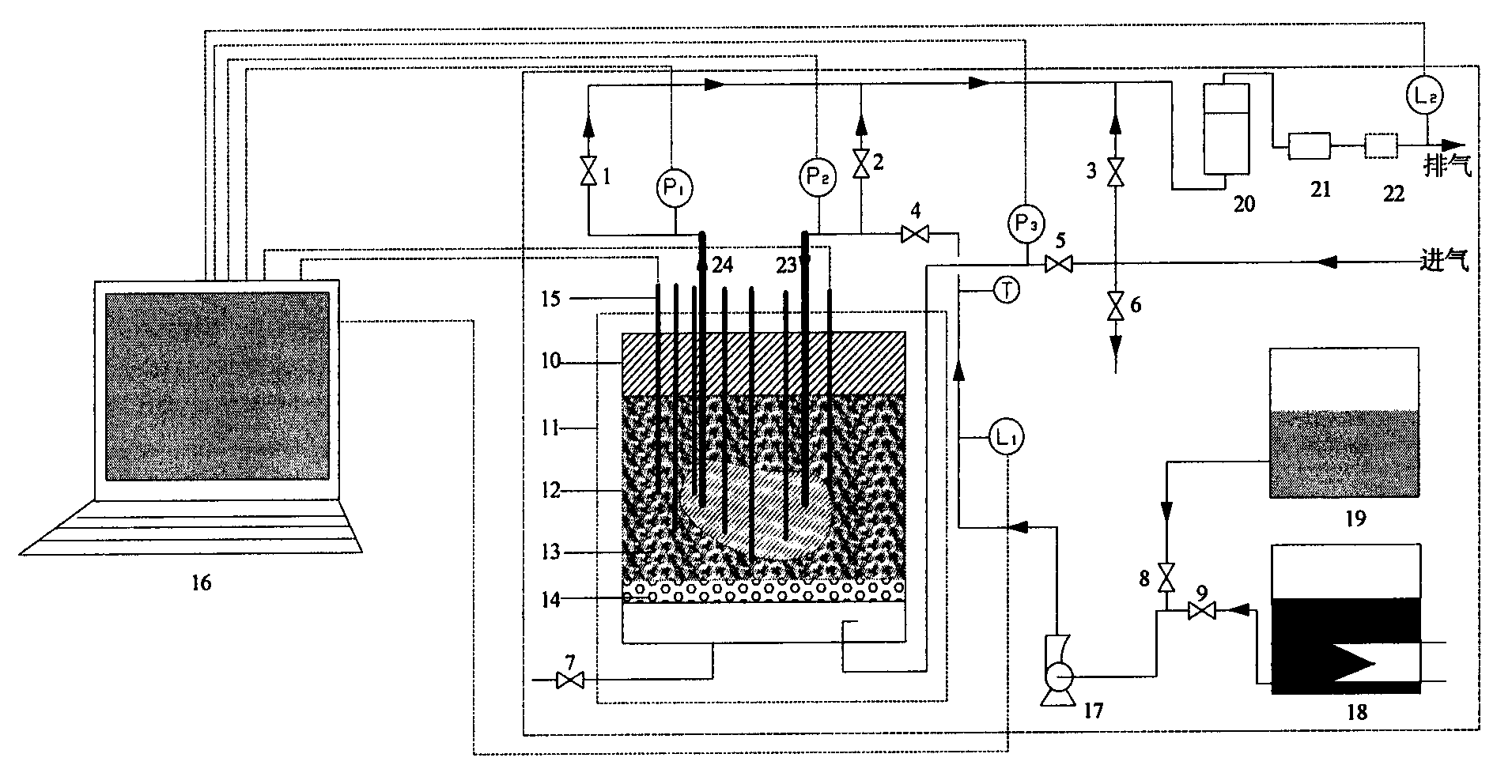

[0073] In this embodiment, as figure 1 In the natural gas hydrate mining simulation experiment device shown, the high-pressure reactor 12 is made of stainless steel, the effective height of the reactor 12 is 100mm, the inner diameter is 300mm, and the total volume is about 7L. The perforated steel plate 14 in the reactor divides the reactor into upper and lower parts, the volume of the upper part is about 6L, and the volume of the lower part is about 1L. After hydrate formation, the upper part of the porous steel plate 14 is hydrate deposits, and the lower part is free gas. The design pressure of the reactor 12 is 16MPa. 24 small perforations of Φ3mm and one large perforation of Φ8mm are arranged at different positions of the reactor cover 10 . Insert 16 thermal resistance temperature sensors 15 from the small perforation on the reactor cover to monitor the temperature in the reacto...

Embodiment 2

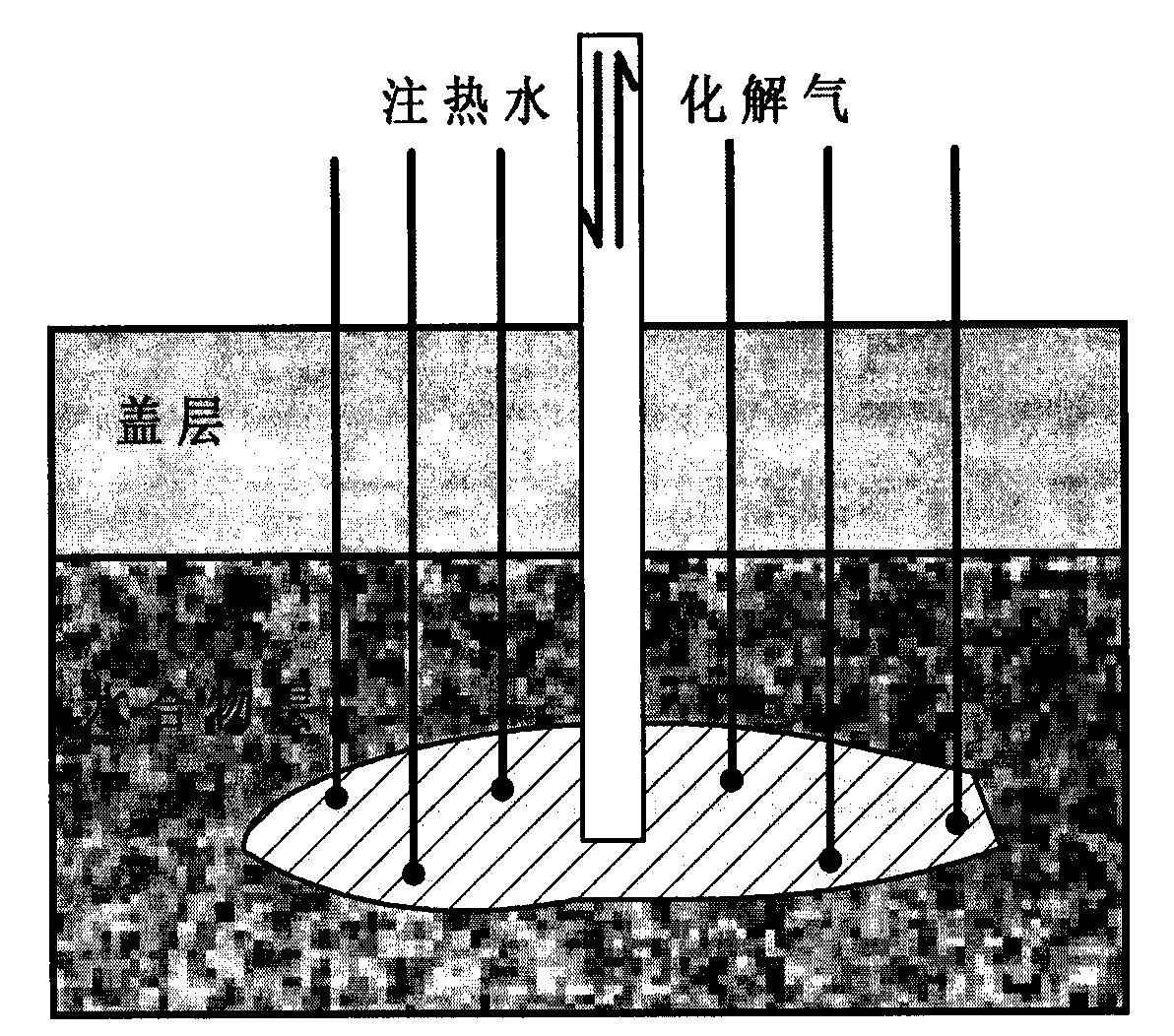

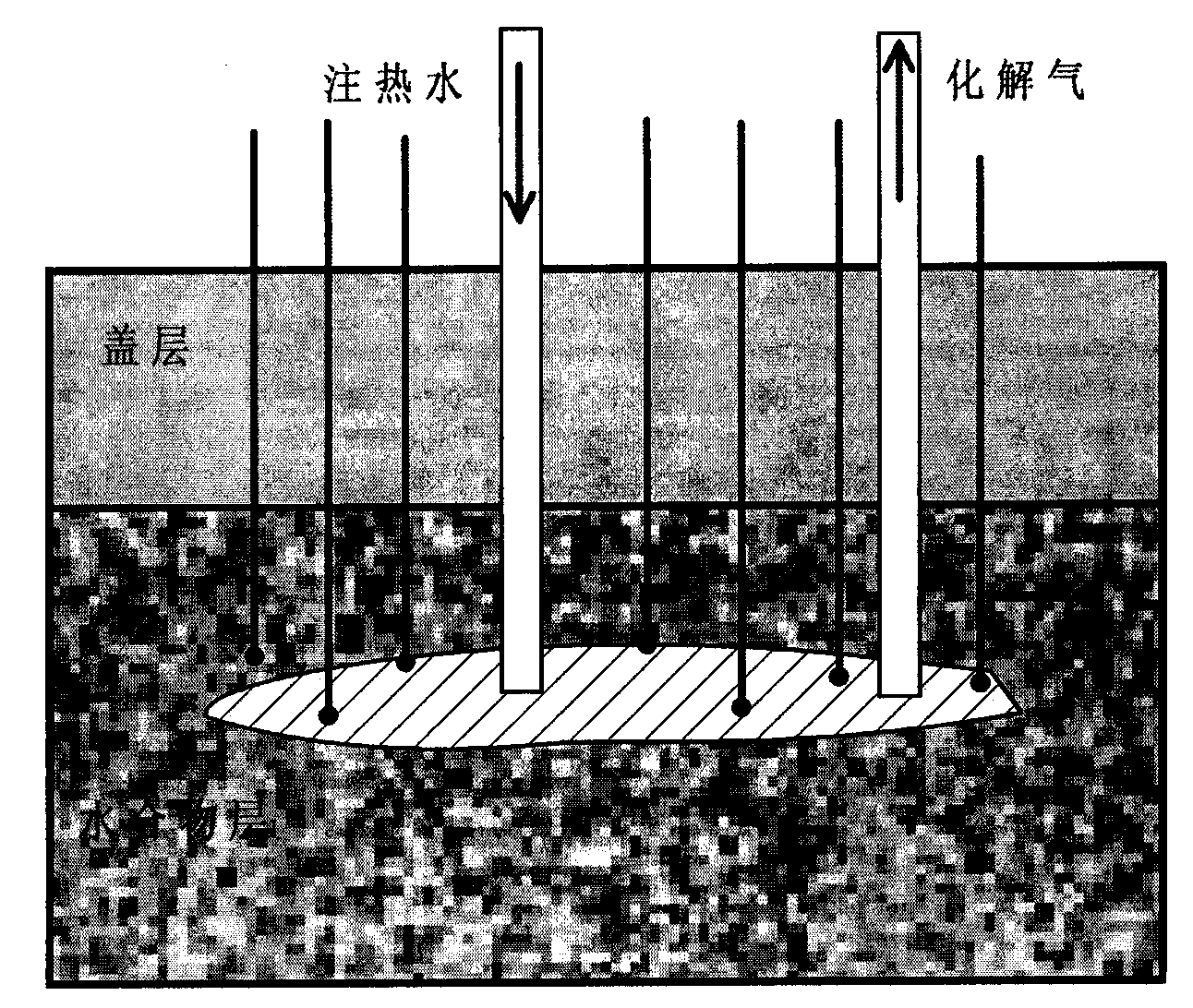

[0091] Example 2: Experimental Simulation of Methane Hydrate Recovery by Hot Water Injection

[0092] In this example, the main use figure 1 The experimental device shown in the figure simulates the process of methane hydrate production by intermittent hot water injection single well huff and puff. The simulation method is mainly carried out as follows:

[0093] (1) Lower the temperature of the low temperature bath control system 11 to about -1°C;

[0094] (2) Quartz sand (20~40 orders) and natural seawater are pressed water saturation 20%, after fully cooling in the environment of 0~1 ℃, mix evenly, put into the reaction kettle 12 until fully filling the reaction kettle ( In this embodiment, the porous partition 14 is not provided in the reaction kettle 12), and the porous medium can be appropriately compacted according to the experimental pressure (porosity 38.7%);

[0095] (3) cover reactor cover 10, insert thermal resistance temperature sensor 15 from the small perforati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com