Temperature sensor

A technology of temperature sensor and temperature sensing element, applied in thermometers, application of thermometers, parts of thermometers, etc., can solve problems such as disconnection, extrusion to the rear side, and decrease in strength of the joint 510, so as to improve reliability, reduce Small thermal stress, the effect of preventing wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

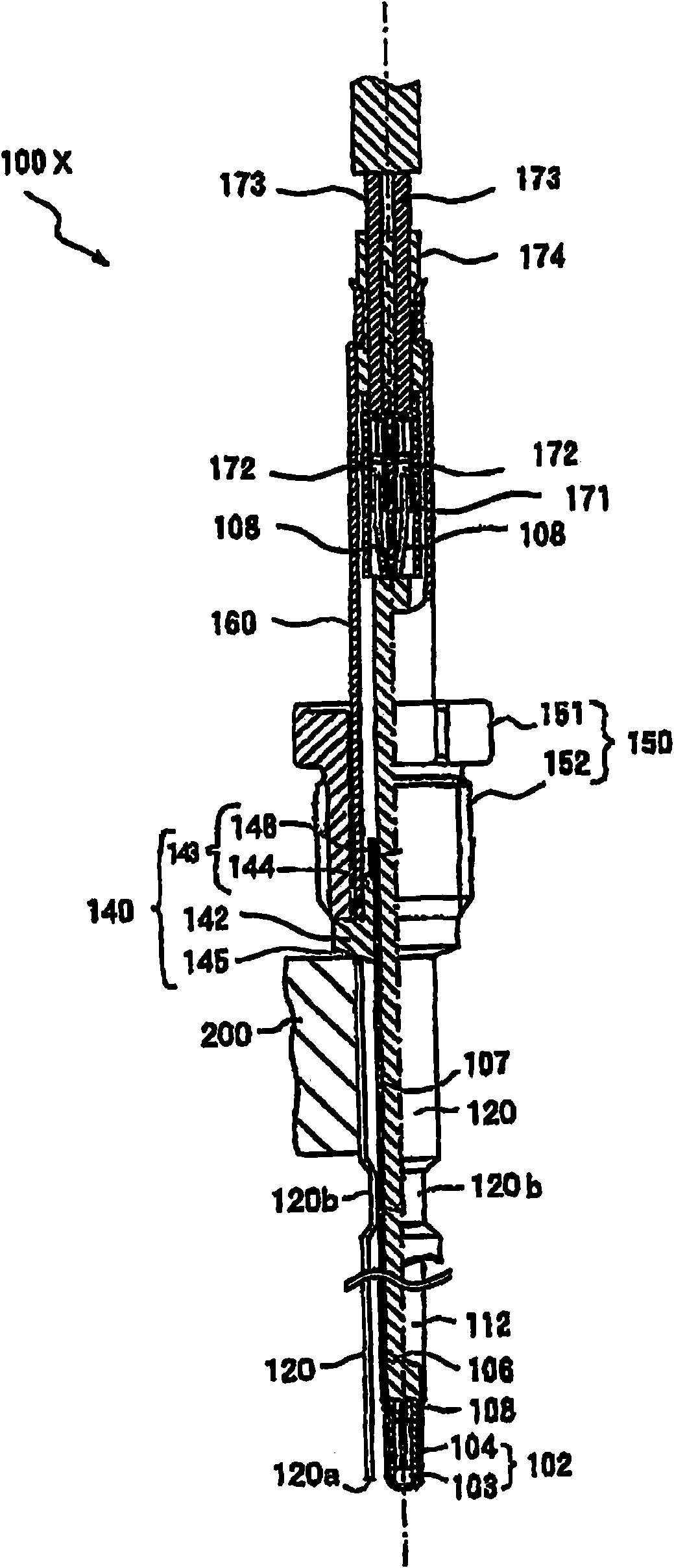

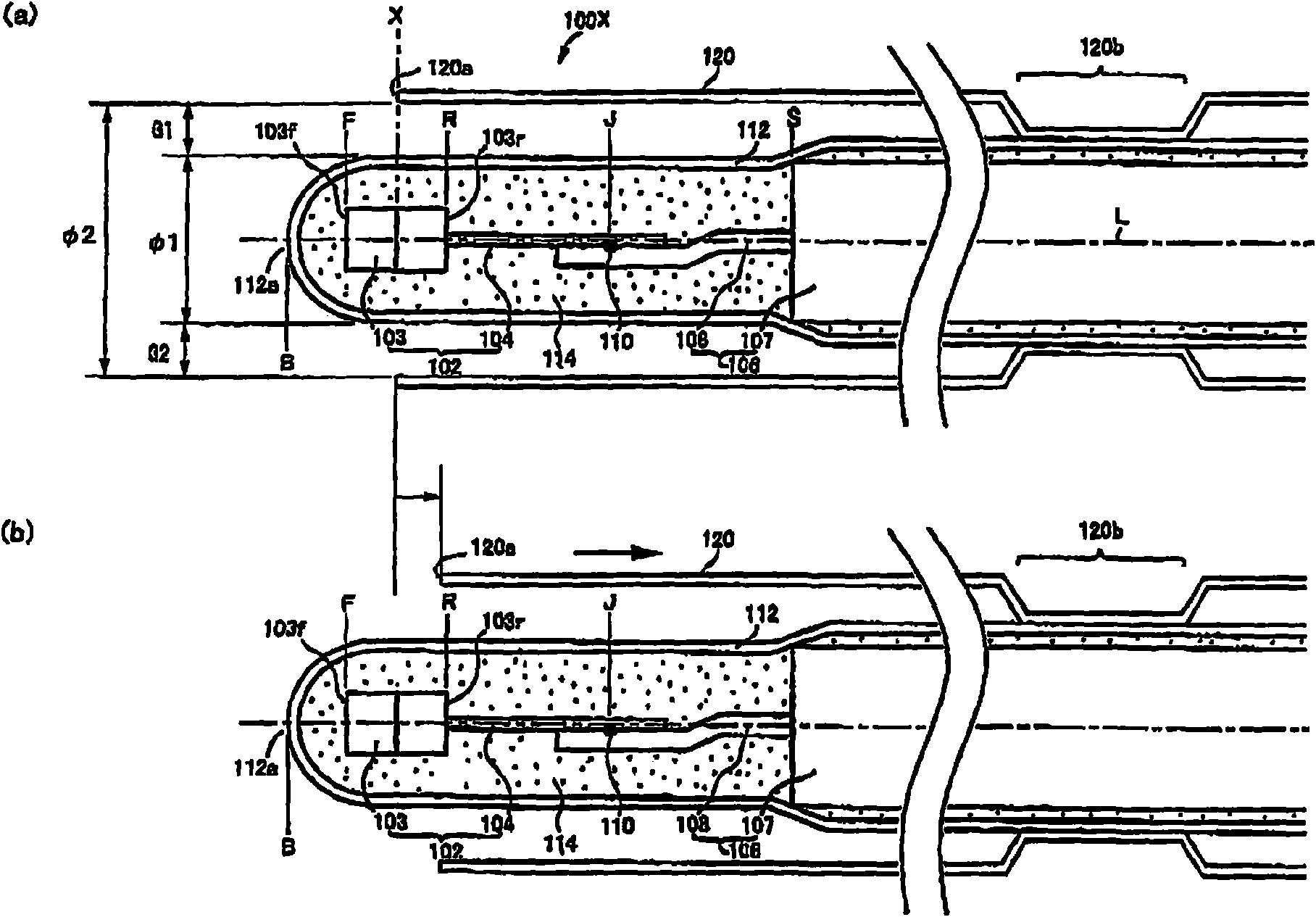

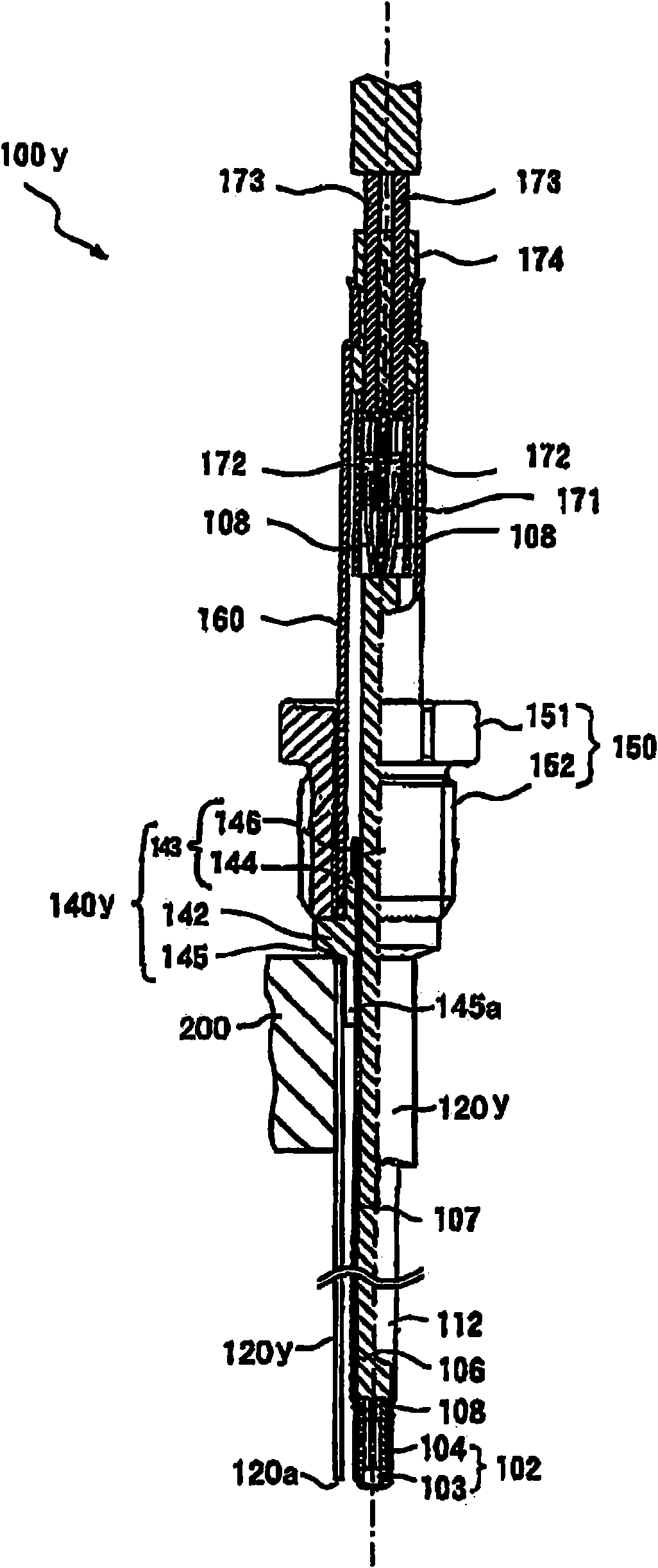

[0079] Make a temperature sensor like this: with figure 1 In the structure shown, the outer diameter of the inner cylinder 112 is 2.65mm, and the outer cylinders 120 with different inner diameters are installed so that the gap between the outer cylinder 120 and the inner cylinder 112 ( figure 2 The value of (G1+G2) / 2) is the value shown in Table 1.

[0080] The temperature sensor was installed in a predetermined cavity, and heated air at 800° C. was blown into the cavity for 5 minutes from an external burner. Afterwards, the operation of the burner was stopped, and air at room temperature was blown into the cavity for 1 minute to cool it down. This heating and cooling was regarded as one cycle, and the thermal history of the number of cycles shown in Table 1 was applied to the temperature sensor in the chamber. In addition, the cavity is swept and vibrated at a frequency of 150 to 3000 Hz while the heat process is being applied. After the experiment was over, the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com