Automatic argon arc welding laminating apparatus and use method thereof

A kind of argon arc welding and automatic technology, which is applied in the field of high-efficiency and energy-saving motor stator core press-fitting production equipment, which can solve the problems of motor temperature rise, temperature rise, and punching deformation at both ends of the product, so as to improve efficiency and quality , Reduced temperature rise, improved heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

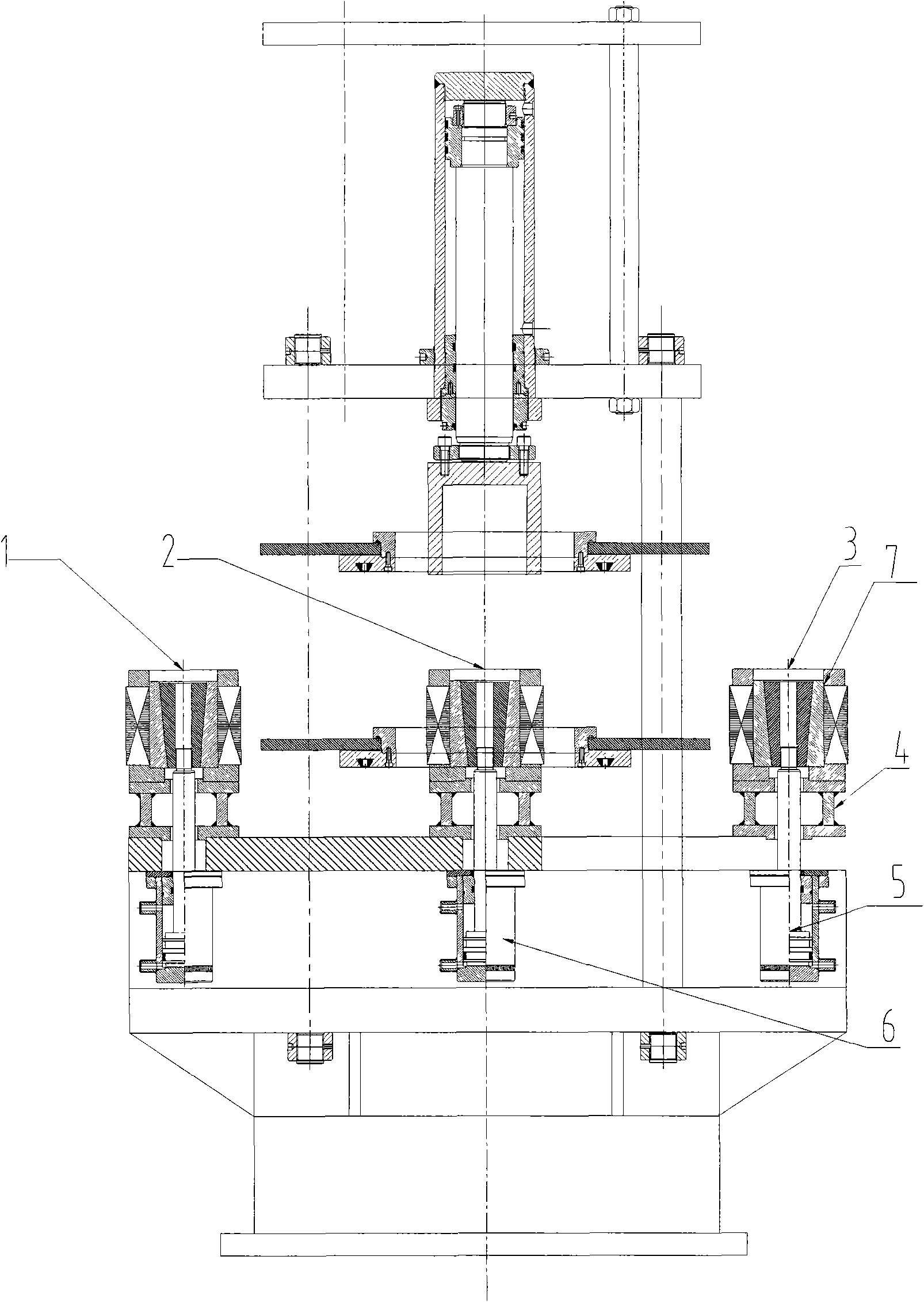

[0009] The three-station automatic argon arc welding machine of the equipment in the present invention consists of: two lamination stations (1) (3) and one press-fit automatic welding station (2), two lamination stations (1) ) (3) each has a set of press-fit tires (4) and positioning and tensioning oil cylinders (5), the slope function is realized by a set of automatic swing mechanism (6), and the slope can be adjusted according to technological requirements; the present invention The production method is as follows: install the mold (4) on the positioning cylinder (5) and check the quality of the mold → weigh the sleeve and tighten it, place the flange (7) on it and press it → remove the stator core from the stack The sheet station (1) moves to the welding lamination station (2) and presses it down → put the welding torch fixing ring on the lower arc starting position → adjust the distance of the welding torch, start the welding process, and start welding work → tighten the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com