Non-inductance electric heating resistance device

A technology of electric thermal resistance and electric heating device, applied in the direction of heating element shape, etc., can solve the problems of unfavorable resistance effect, affecting the normal operation of equipment control circuit, etc., and achieve the effect of ensuring working performance and working life, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

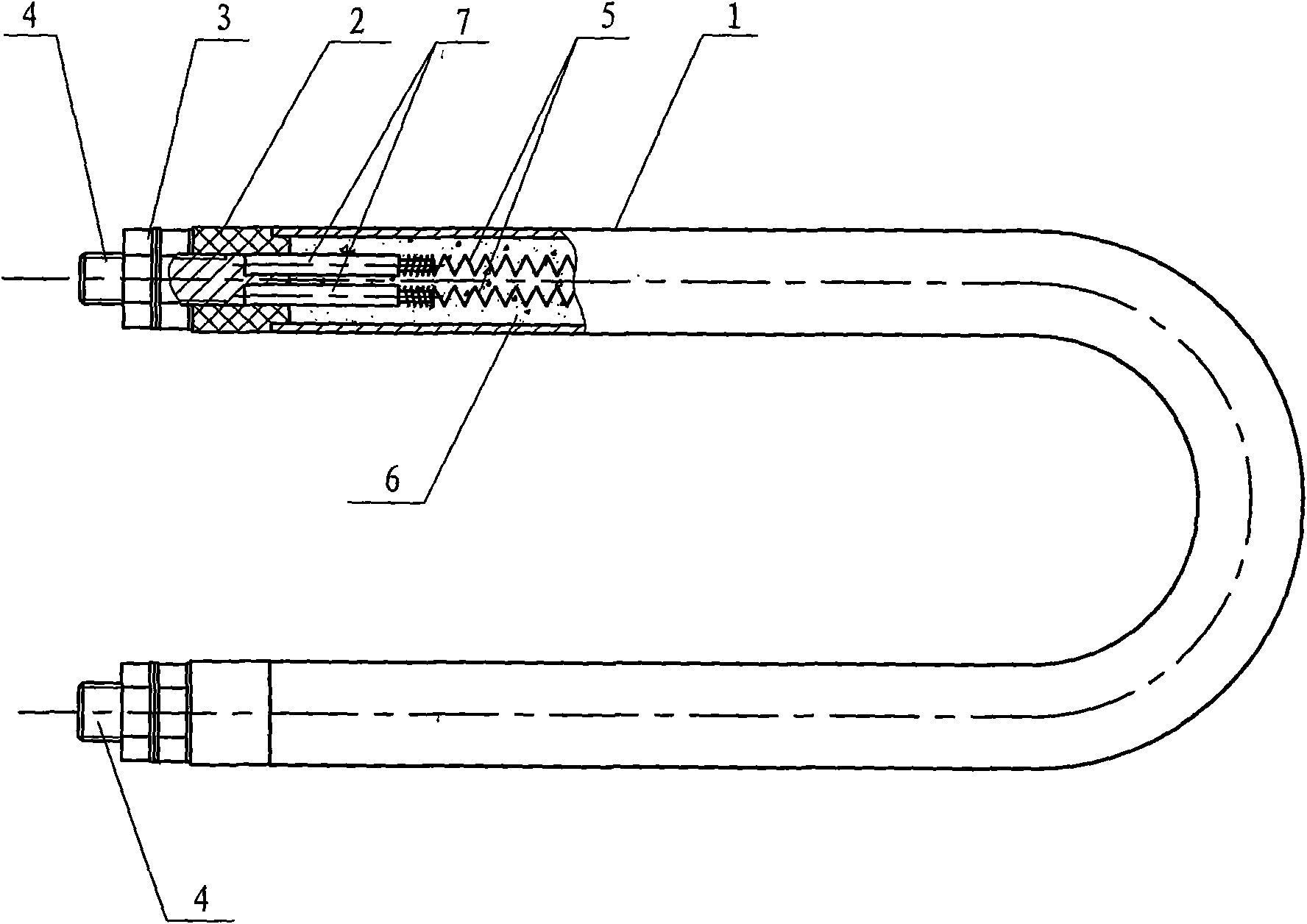

[0012] As shown in the figure, the electric heating resistance device of the present invention includes a U-shaped electric heating tube outer tube 1, and the electric heating tube outer tube 1 and the terminal post 4 are insulated, isolated and fastened by insulating rings 2 and fasteners 3 at both ends. Two helical resistance wires 5 threaded side by side in the outer tube of the electric heating tube have opposite helical directions and are connected in parallel between the terminal posts 4 at both ends. The resistance wires 5 can be directly connected to the terminal posts 4 or can be connected to Terminal connection, in the illustrated embodiment, the terminal 4 is embedded and welded firmly with the two lead-out rods 7 wrapped around the welding resistance wire 5 . The space between the resistance wire and the inner wall of the outer tube of the electric heating tube is filled with magnesium oxide powder as the thermally conductive insulating material 6 . The material, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com