Combination piece of metal and plastic and manufacture method thereof

A manufacturing method and technology of joints, applied in the structural form of radiation units, electrical components, thin material processing, etc., can solve the problems affecting the strength of joints, large gaps, easy loosening, etc., and achieve good integration and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

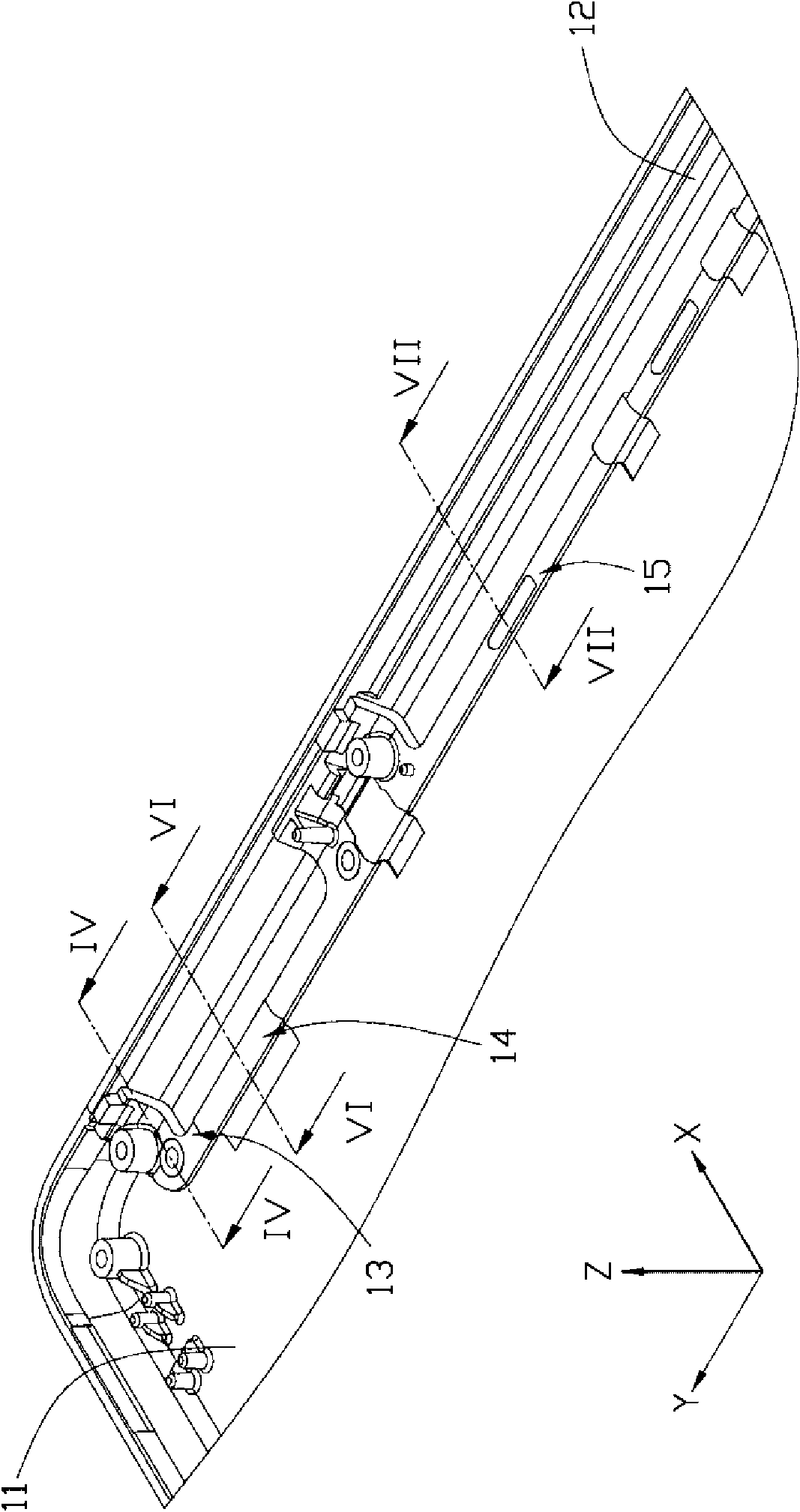

[0015] The combination of metal and plastic and its manufacturing method of the present invention will be further described in detail with reference to the accompanying drawings and preferred embodiments.

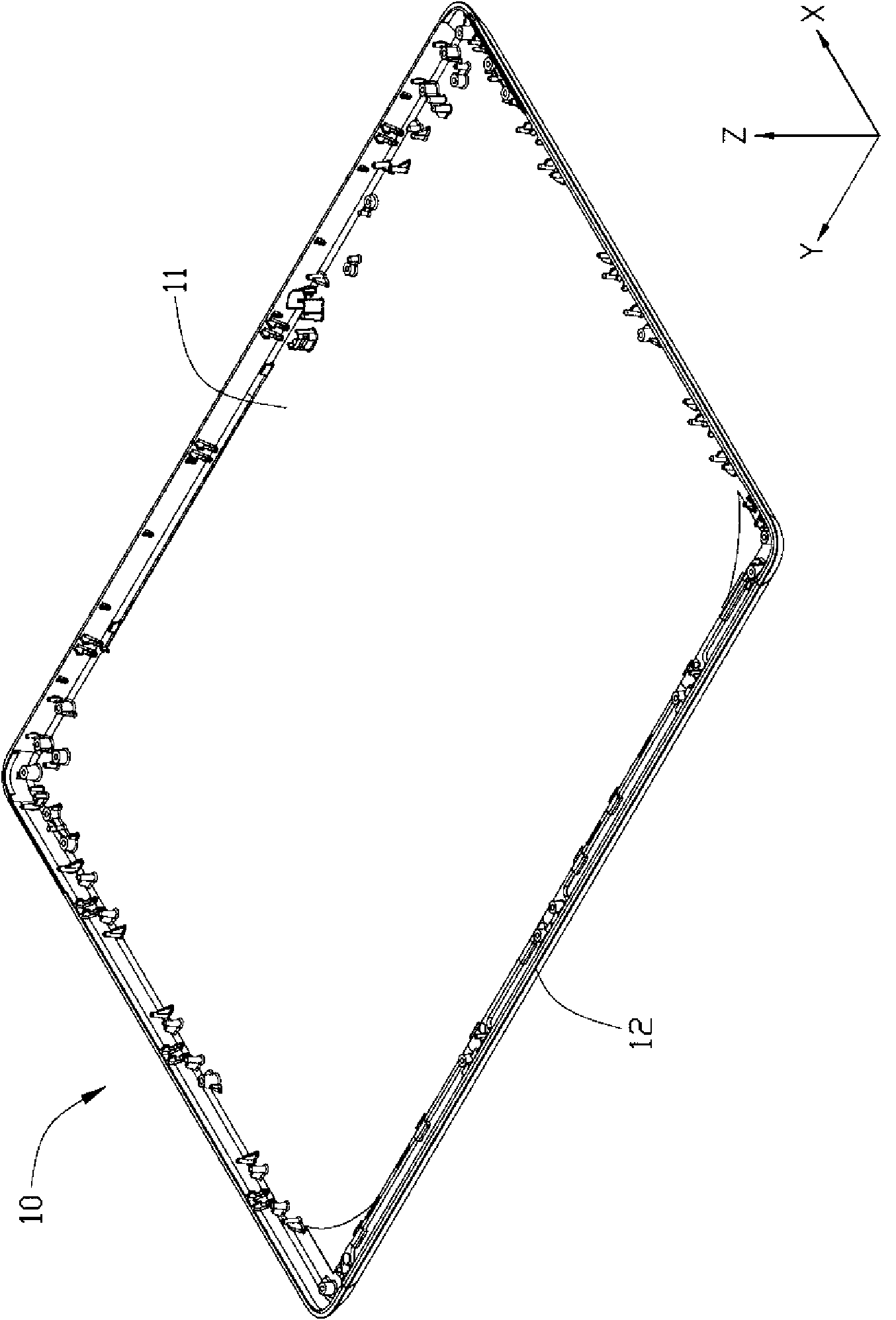

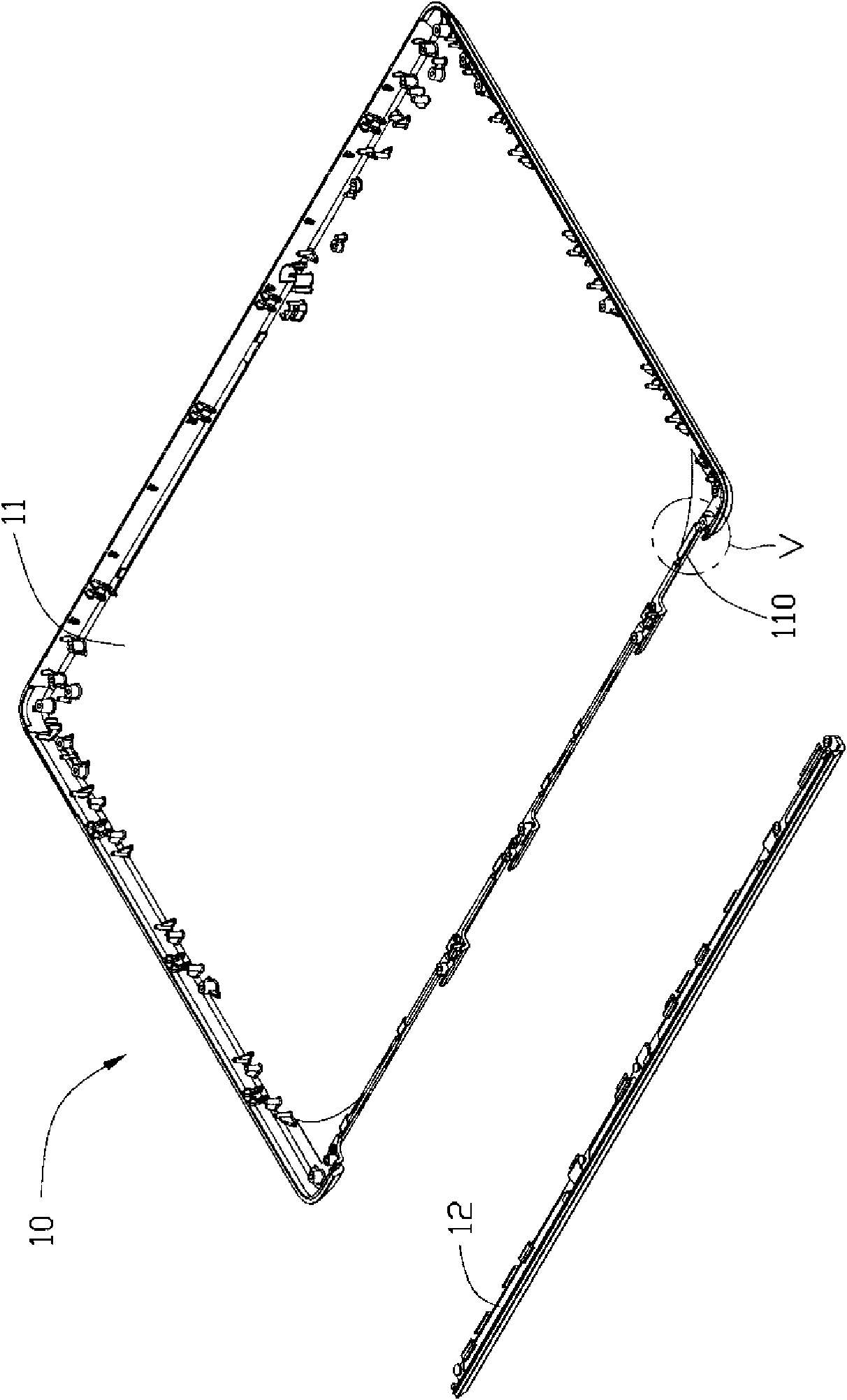

[0016] See figure 1 and figure 2 The metal-plastic combination part 10 of the preferred embodiment 1 of the present invention is an electronic device casing, which includes a metal body 11 and a plastic part 12 combined with the metal body 11 . The metal body 11 is generally a rectangular metal cover, and at least one positioning portion 110 is provided on a side of the metal body 11 combined with the plastic portion 12 for tightly combining with the plastic portion 12 to form a positioning structure during the molding process. The material of the metal body 11 can be selected from one of magnesium alloy, aluminum alloy or titanium alloy.

[0017] The plastic part 12 is generally long and can be formed on one side of the metal body 11 where the positioning part 110 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com