Method for baking tobacco leaves and baking room

A curing method and tobacco leaf technology are applied in the directions of tobacco, tobacco preparation, application, etc., to achieve the effects of improving the quality of tobacco leaves, improving the quality of flue-cured tobacco, and reducing the energy consumption of curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

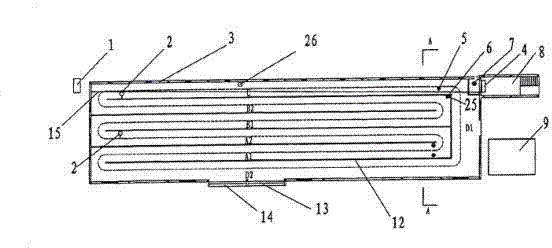

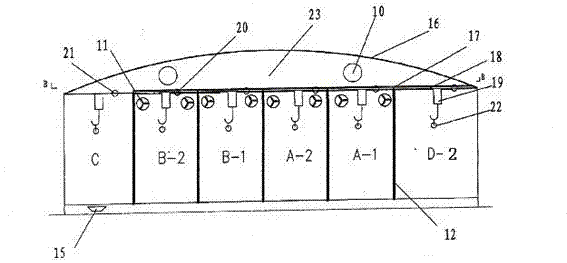

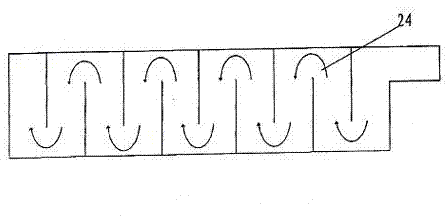

[0031] Embodiment: referring to accompanying drawing, set up flue-cured room 3 long 40m, wide 12.8m (can be adjusted according to actual needs scale), in width direction by 1.85 meter intervals, there are disassembleable, end-to-end staggered partitions 12, the barn is separated into 6 parallel drying tunnels, next to the heat source is the first drying tunnel (the latter analogy) is the dry tendon area C, and the latter are respectively the area after color fixation B2, the area before color fixation B1, the area after yellowing A2, the area before yellowing A1, In the feeding and moisture regaining zone D2, each drying tunnel is connected end to end to form a continuous drying tunnel for tobacco leaf moving and baking. There is an independent smoke inlet door 14 and a smoke outlet door 13 in the middle of the material feeding and moisture regaining area D2, which can realize the continuous inlet and outlet operation of flue-cured tobacco. There is a heating chamber 8 adjacen...

Embodiment 2

[0036] Embodiment 2: As mentioned above, remove the dividing plate that separates the drying tunnel, open the lower layer of solar panel and install electric black and white two-color sunshade on it to become a solar greenhouse.

Embodiment 3

[0037] Embodiment 3: As mentioned above, an auxiliary controllable temperature and moisture replenishing channel connected to a heat source and with one or more electronically controlled valves can also be set in each drying tunnel to assist in adjusting the temperature and humidity at various points in the drying tunnel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com