Rolling mill emulsifying liquid outer cyclic heating method and heating device

A heating method and heating device technology, applied in lighting and heating equipment, rolls, metal rolling, etc., can solve the problems of uneven heating of emulsion, affecting the quality of emulsion, and inconvenient maintenance of equipment, so that the quality is not affected, Strong temperature control ability and good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

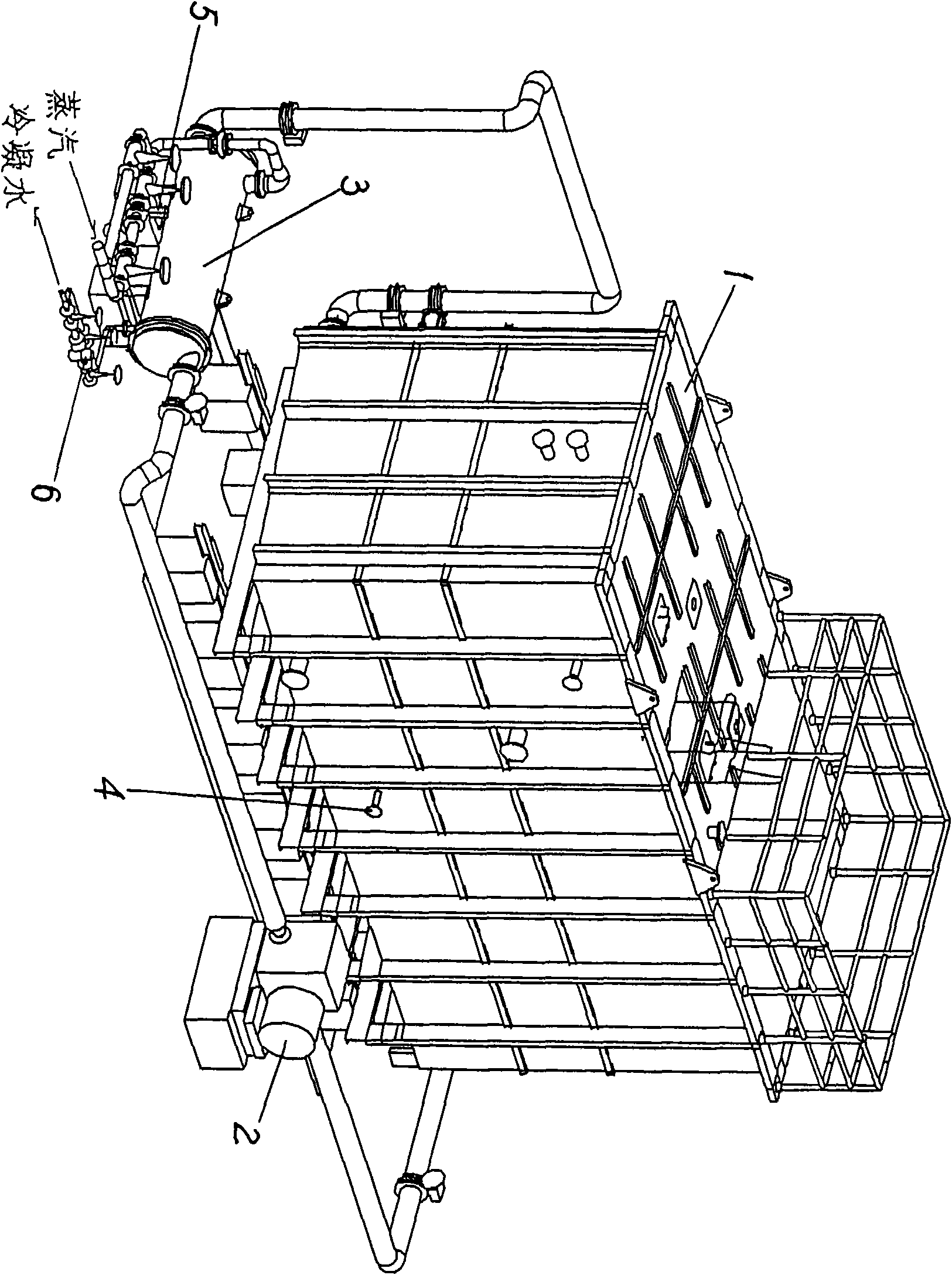

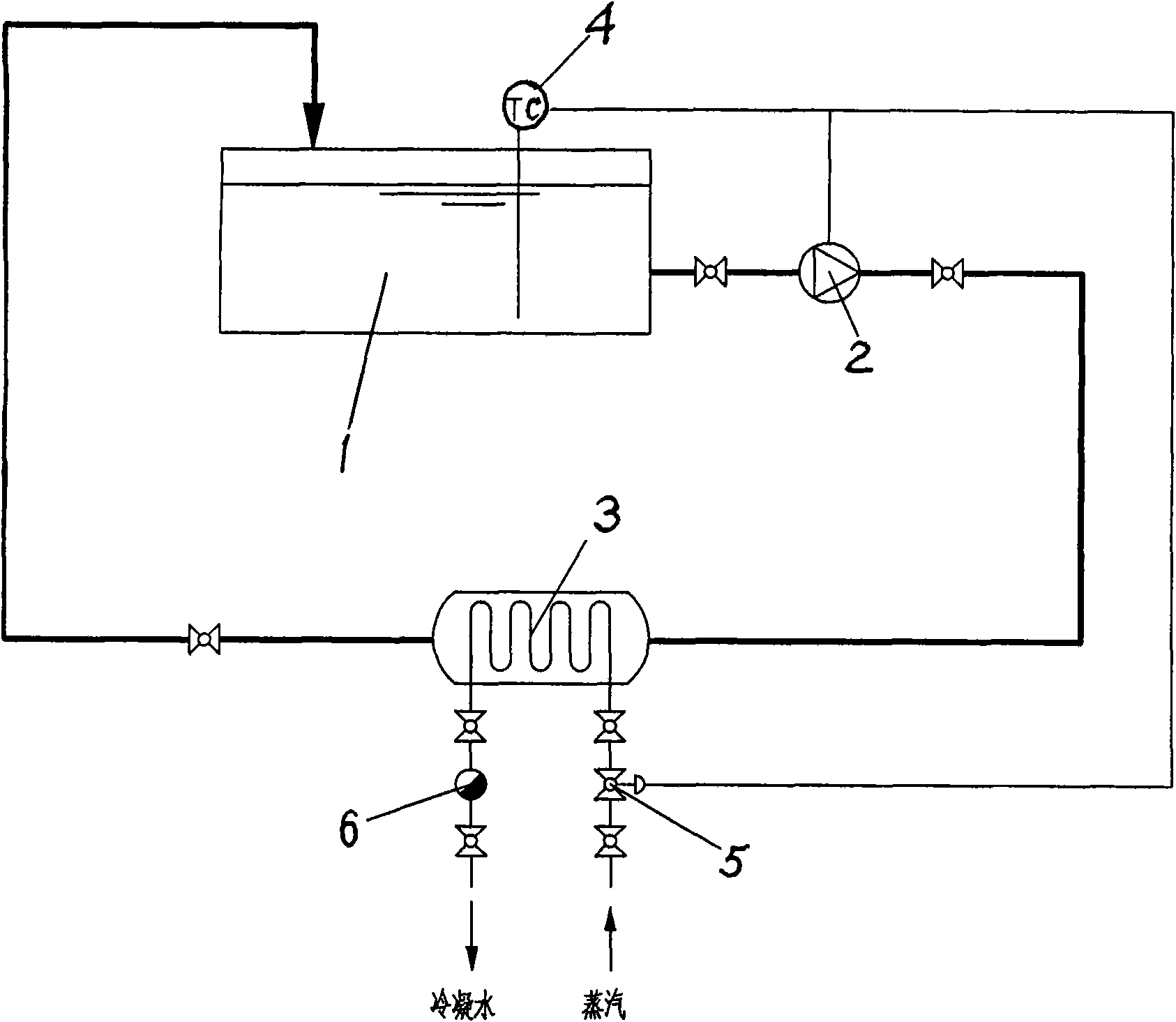

[0039] The preferred embodiments of the rolling mill emulsified liquid external circulation heating method and heating device of the present invention will be described in detail below with reference to the accompanying drawings.

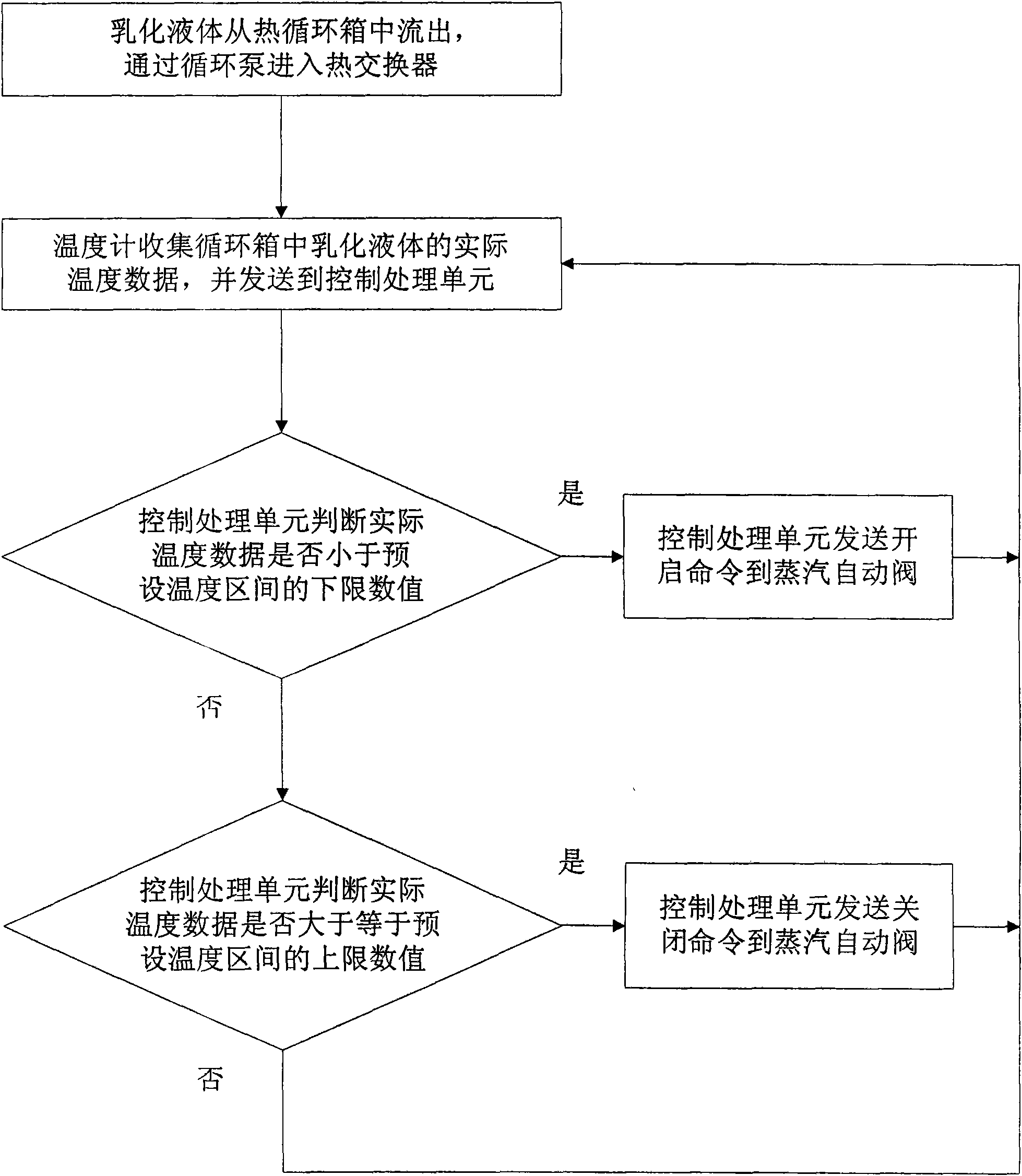

[0040] see figure 1 , according to the rolling mill emulsified liquid external circulation heating method of the present invention, take the following steps:

[0041] A. The emulsified liquid flows out from the heat circulation tank and enters the heat exchanger through the circulation pump.

[0042] B. The thermometer collects the actual temperature data of the emulsified liquid in the thermal cycle box and sends it to the control processing unit.

[0043] C. The control processing unit compares the actual temperature data with the value of the preset temperature range, and judges whether the actual temperature data is less than the lower limit value of the preset temperature range, if so, sends an opening command to the steam control valve, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com