Small numerical control drilling and milling machine and control method thereof

A control method, drilling and milling machine technology, applied in the field of CNC machine tools, can solve problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

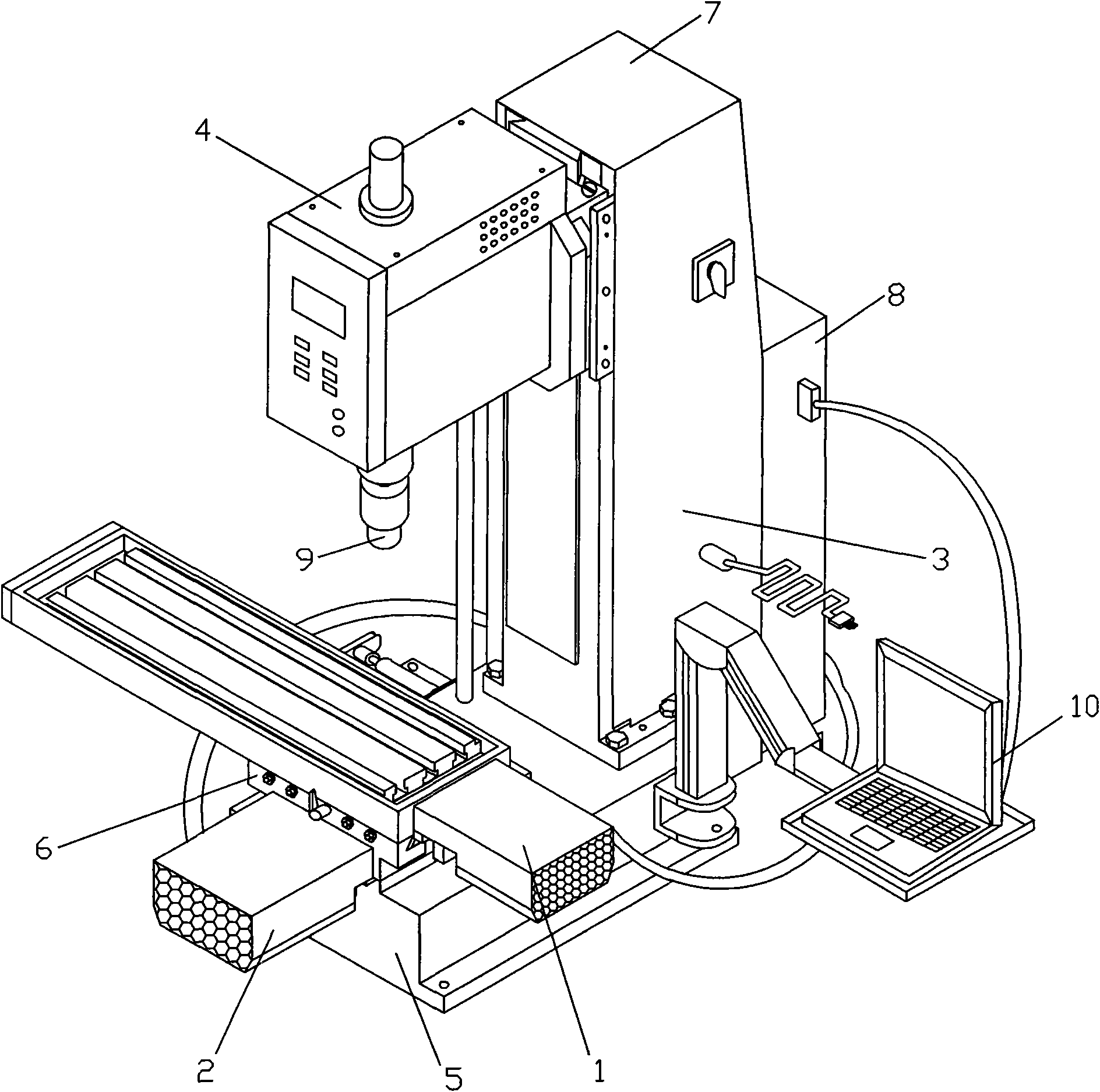

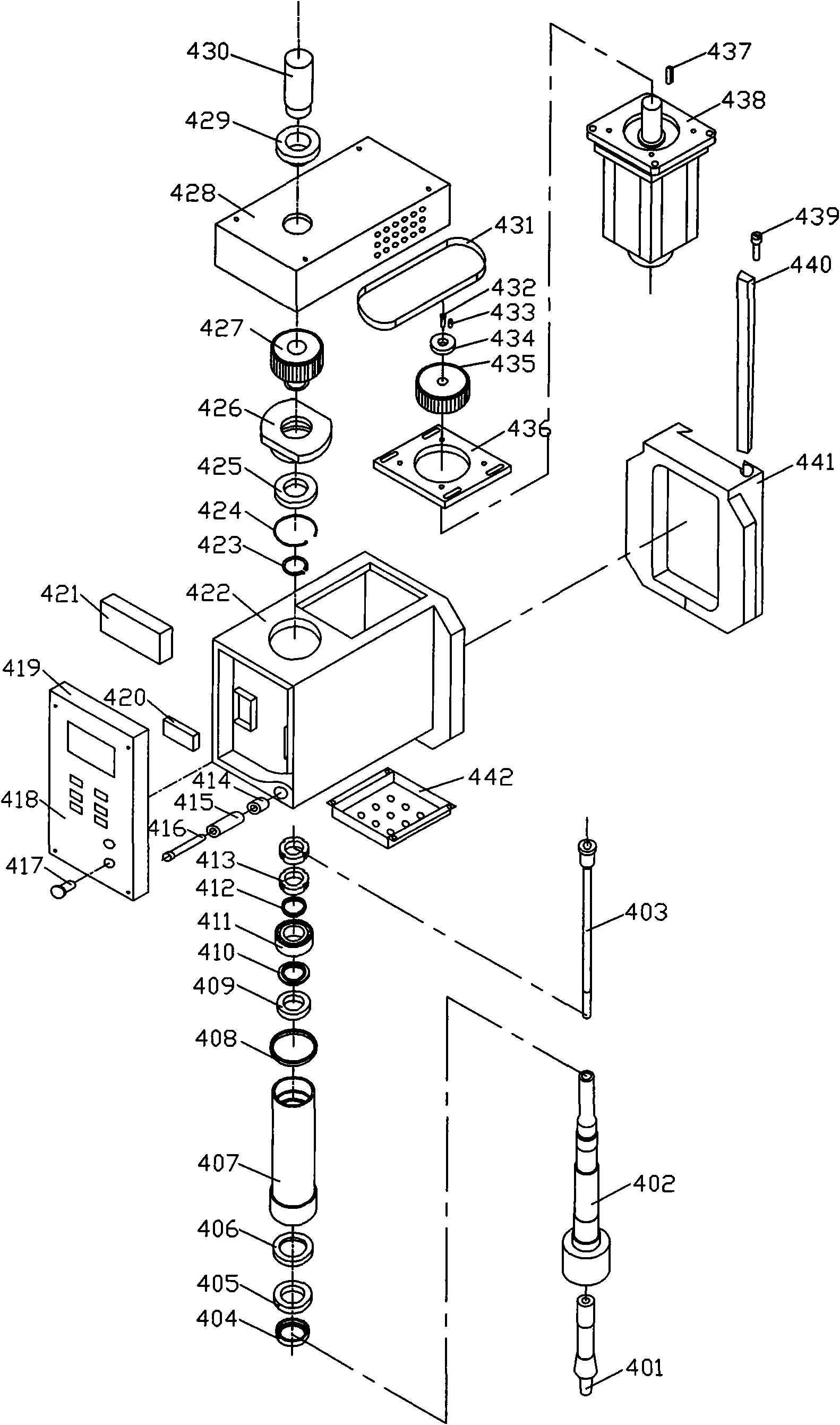

[0031] In conjunction with the accompanying drawings, the present invention takes the household numerical control drilling and milling machine of model X4 as an example, which includes an X-axis device 1, a Y-axis device 2, a Z-axis device 3, a spindle device 4, a machine base 5, a carriage 6, and a back cover device 7. Electric cabinet 8 and milling chuck 9 (or drill chuck).

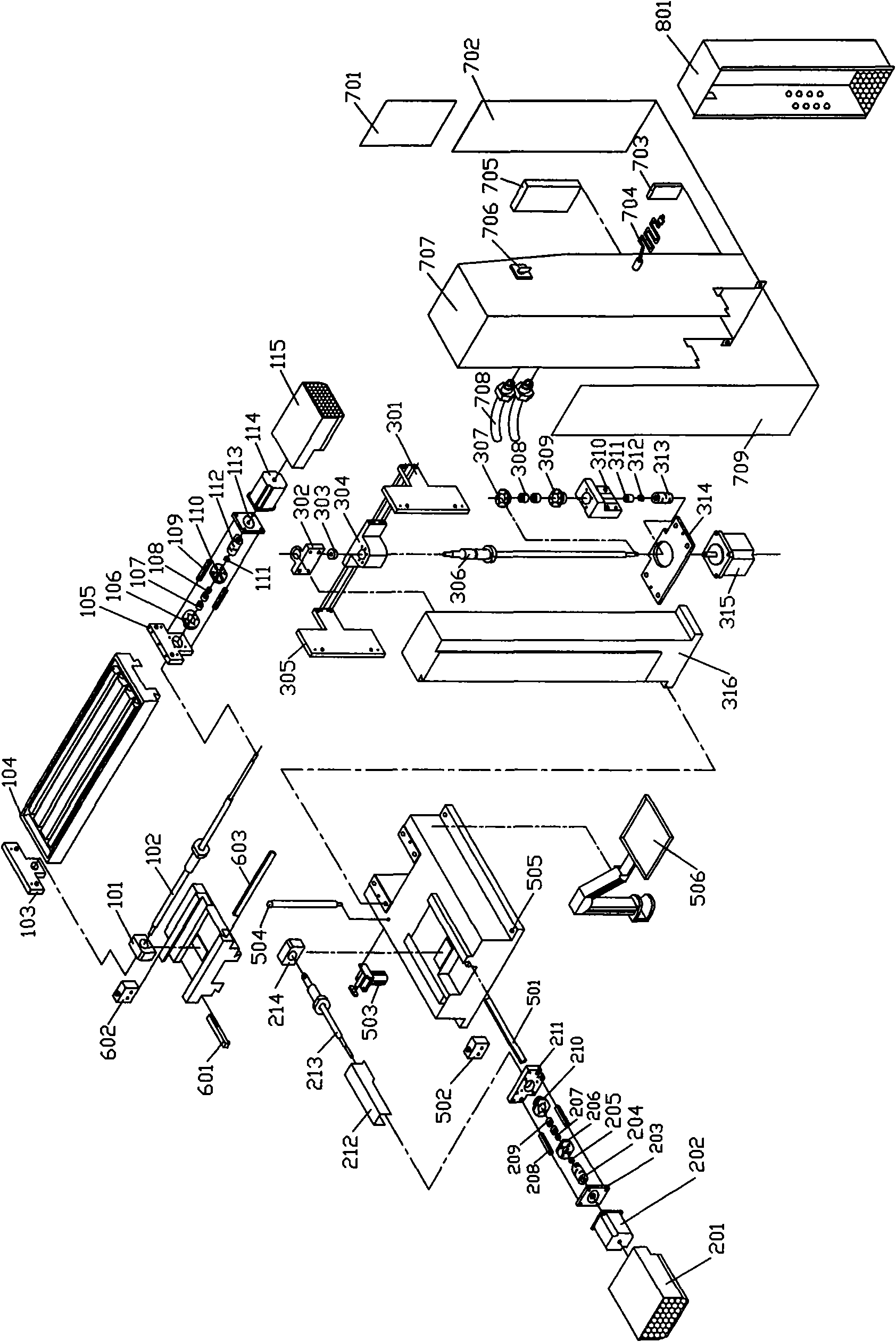

[0032] The X-axis device 1 is supported by an X-axis bearing 103, an X-axis nut seat 101, an X-axis screw 102, a workbench 104, an X-axis screw support 105, an X-axis bearing block 106, and an X-axis bearing 107, First X-axis nut 108, X-axis motor bracket 109, X-axis bearing cover 110, second X-axis nut 111, X-axis coupling 112, X-axis motor base 113, X-axis stepper motor 114 and X-axis motor cover 115 are sequentially connected to form.

[0033] Described Y-axis device 2 is made up of Y-axis motor cover 201, Y-axis stepper motor 202, Y-axis motor base 203, Y-axis coupling 204, the first Y-axis nut 205, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com