Changing device for molds for building block forming machine

A technology of a block forming machine and a conversion device, which is applied to ceramic forming machines, cranes, manufacturing tools, etc., can solve problems such as inconvenience, work-related accidents and economic losses, and narrow installation space for block forming machines and supporting facilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

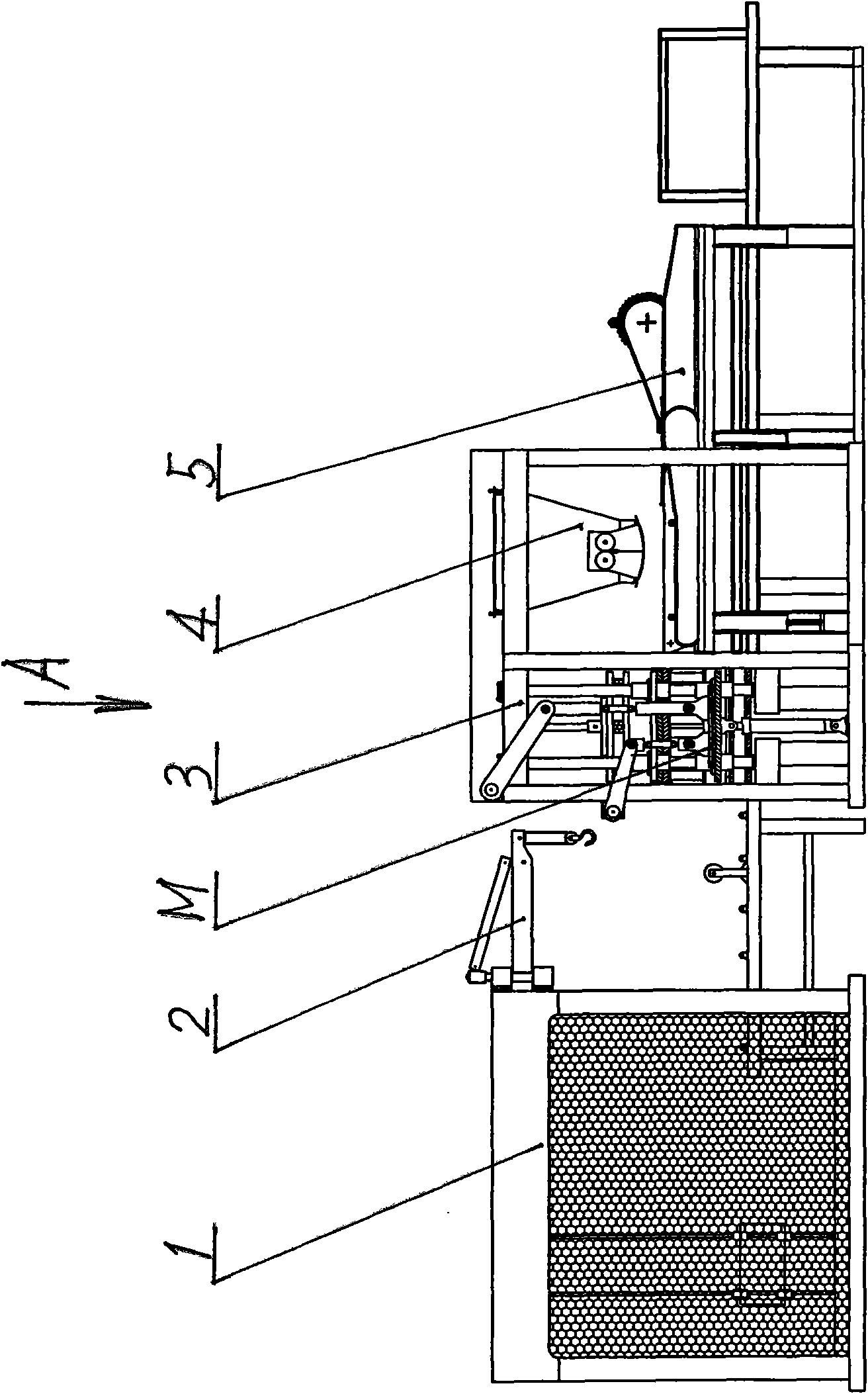

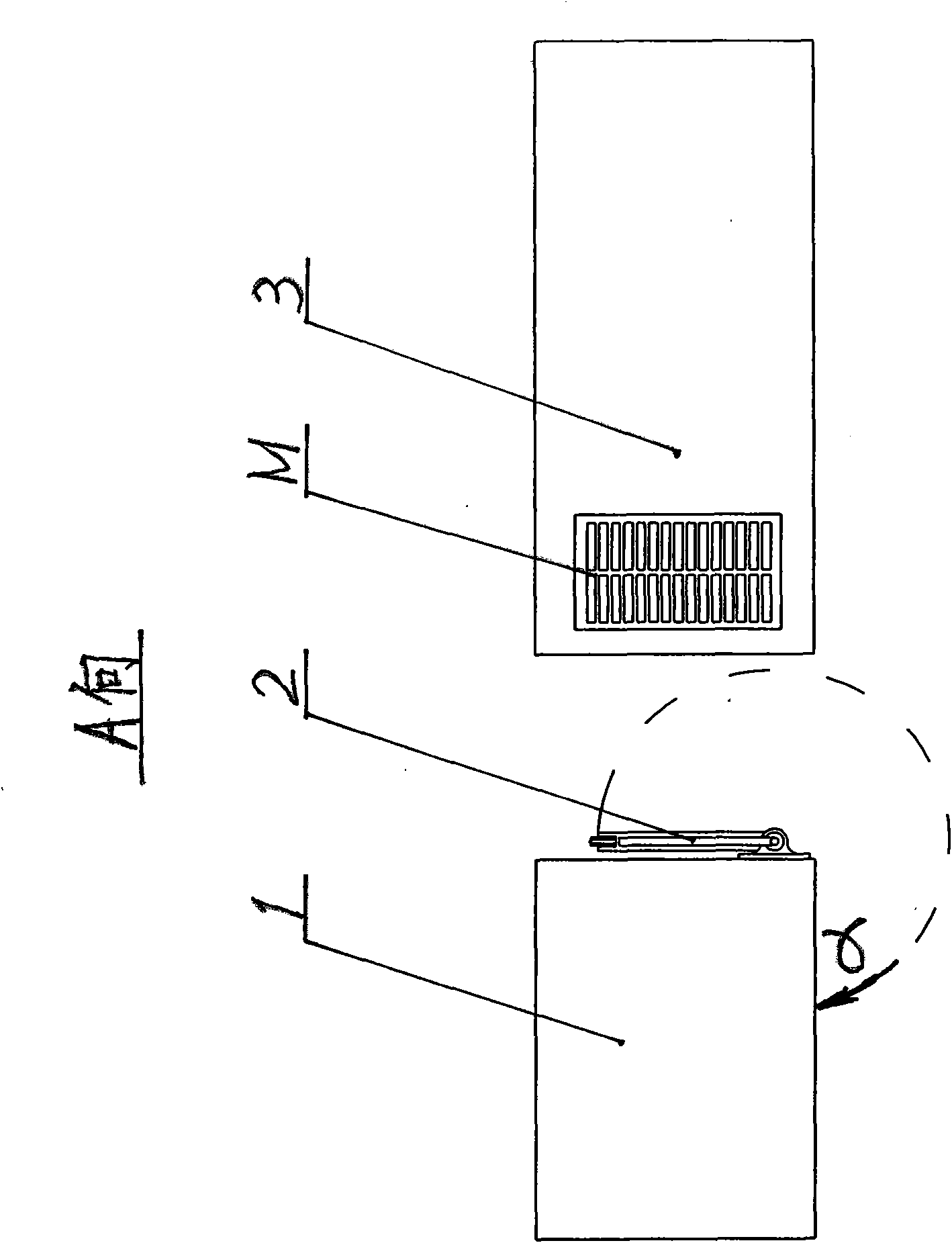

[0011] refer to figure 1 , the rear of the block forming machine 3 is connected to the feeding funnel 4 and the material distribution mechanism 5, the distance between the block forming machine 3 and the stacking machine 1 is very close, and the structure is compact, and the front of the stacking machine 1 facing the block forming machine 3 The upper part of the panel is equipped with a mold conversion device 2

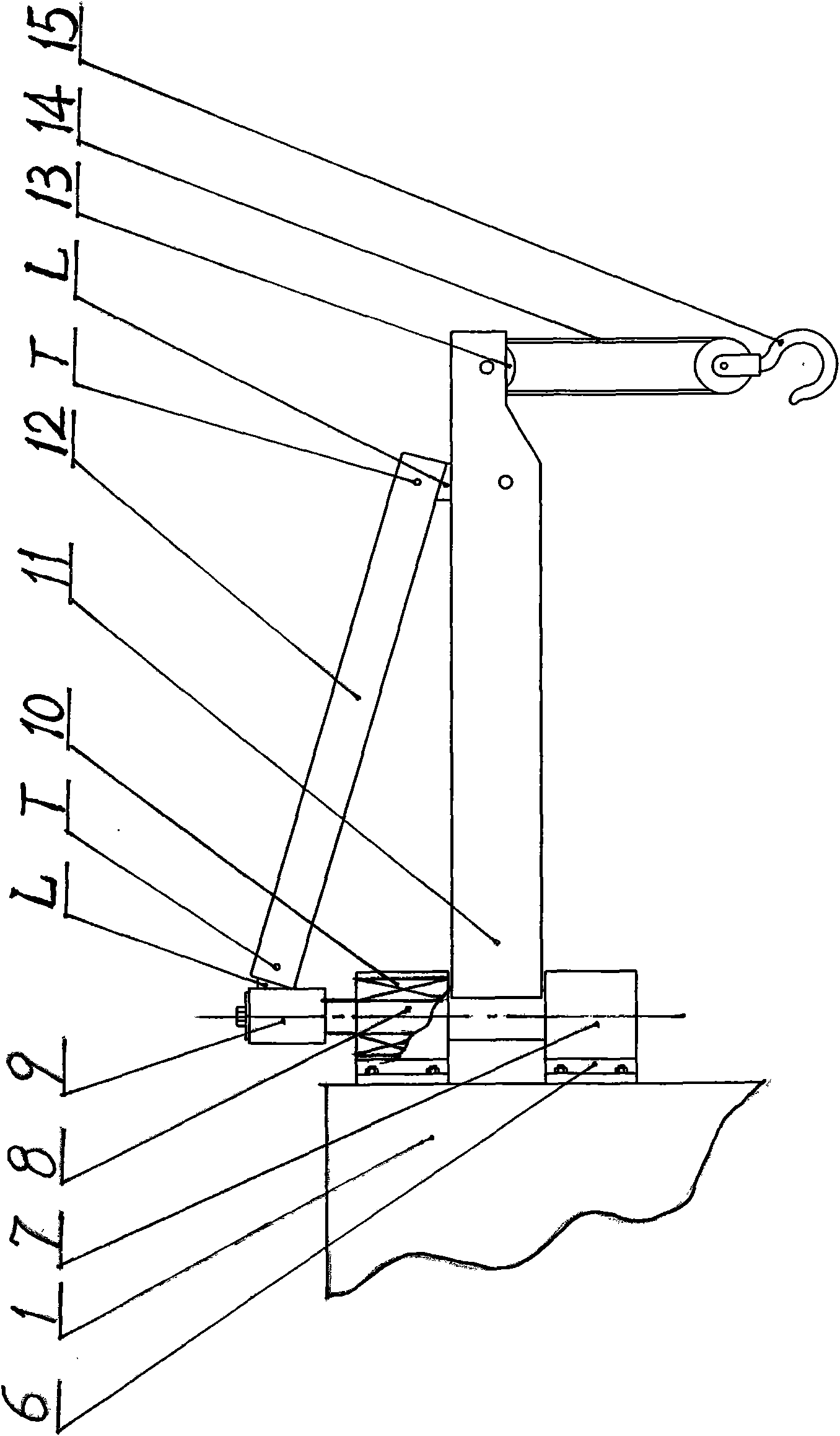

[0012] refer to figure 2 , the structure of the mold conversion device 2 includes: connecting base 6, fixed shaft seat 7, rotating vertical shaft 8, rotating shaft sleeve 9, lifting arm 11, diagonal stay rod 12, steel wire rope 14, pulley hook 15, connecting and fixing on the stack On the top of the front panel of the trigger 1, the fixed shaft seat 7 is equipped with a pressure bearing 10, and the outside is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com