Packaging machine having a lifting unit

A packaging machine and lifting plate technology, applied in packaging machines, lifting devices, packaging and other directions, can solve the problems of affecting the moving time, unfavorable structure height, affecting the cycle performance of the packaging machine, etc., achieving a small structure height and eliminating the risk of bending. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

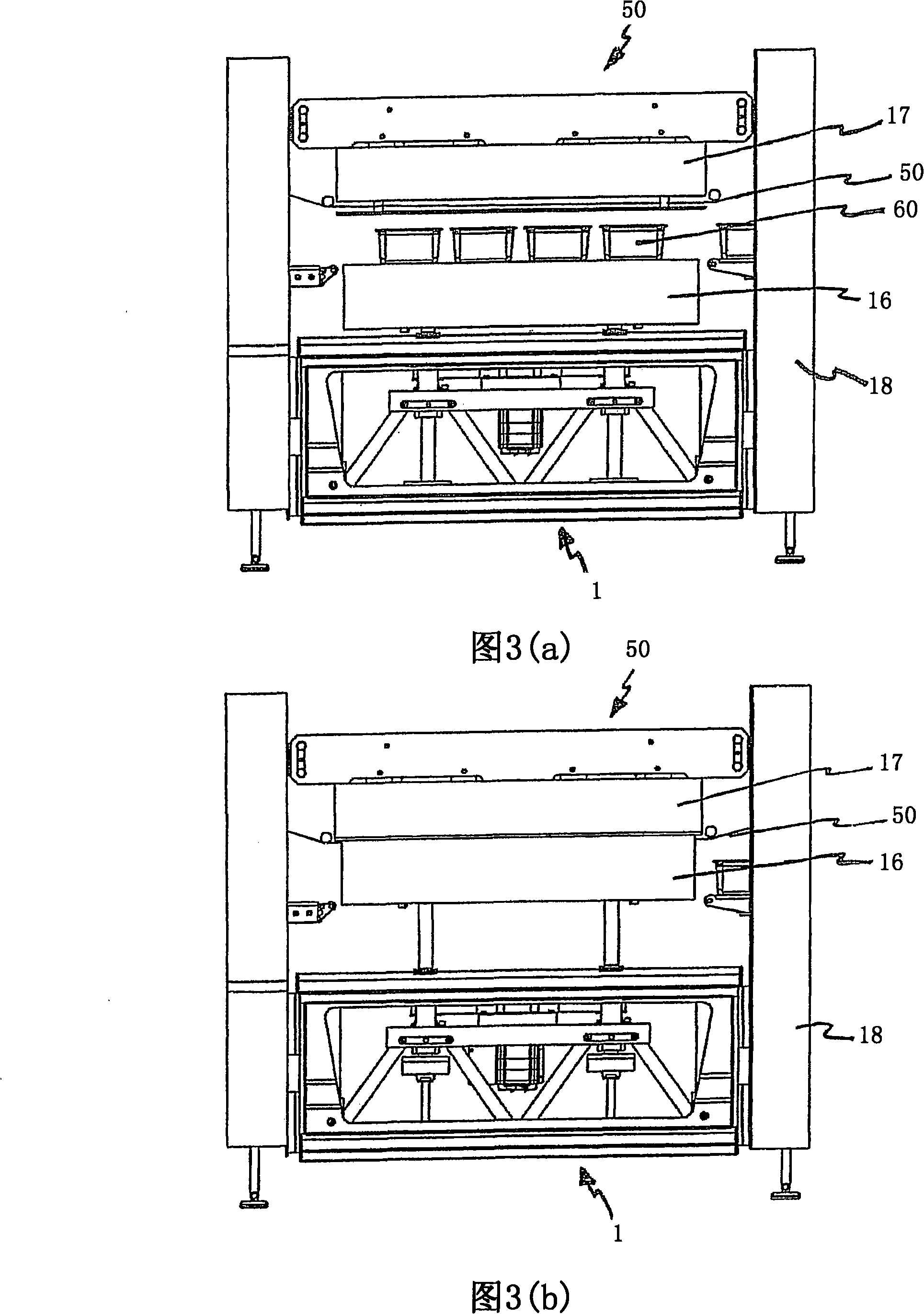

[0016] A first embodiment of the present invention will be described exemplarily in a tray sealing machine (or a tray closure) below with reference to FIGS. 1 to 3b.

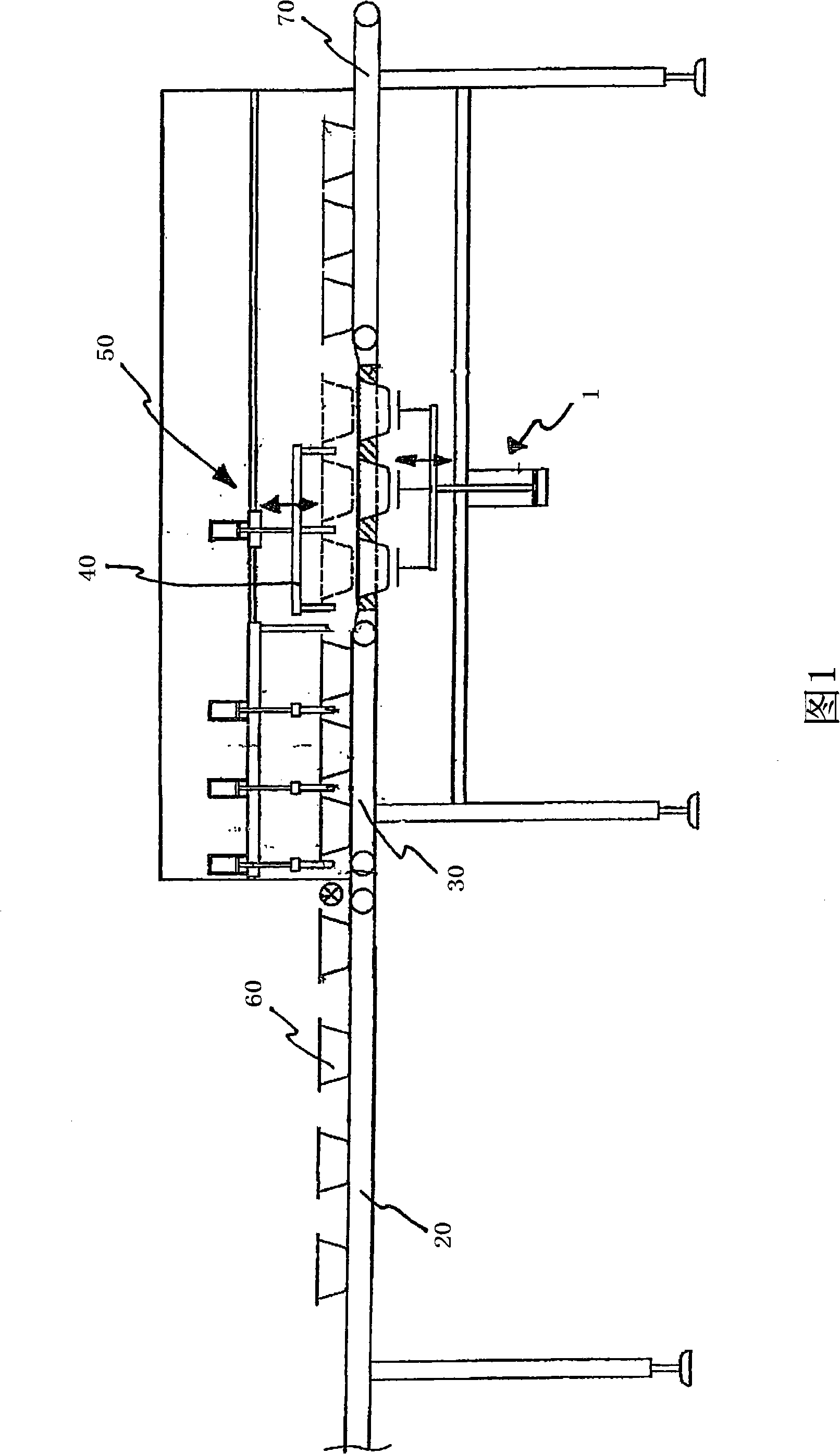

[0017] FIG. 1 shows a tray closure with a first conveyor belt 20 , a second conveyor belt 30 , a third conveyor belt 70 , a gripper 40 , an evacuation and sealing station 50 and a lifting mechanism 1 .

[0018] In operation, the packages 60 are transferred via the first conveyor belt 20 onto the second conveyor belt 30 . The package 60 is conveyed by the gripper 40 into the vacuuming and sealing station 50 . The sealing takes place by lifting the package 60 by the lifting mechanism 1 . The vacuumized and sealed package 60 is finally transported away by the third conveyor belt 70 .

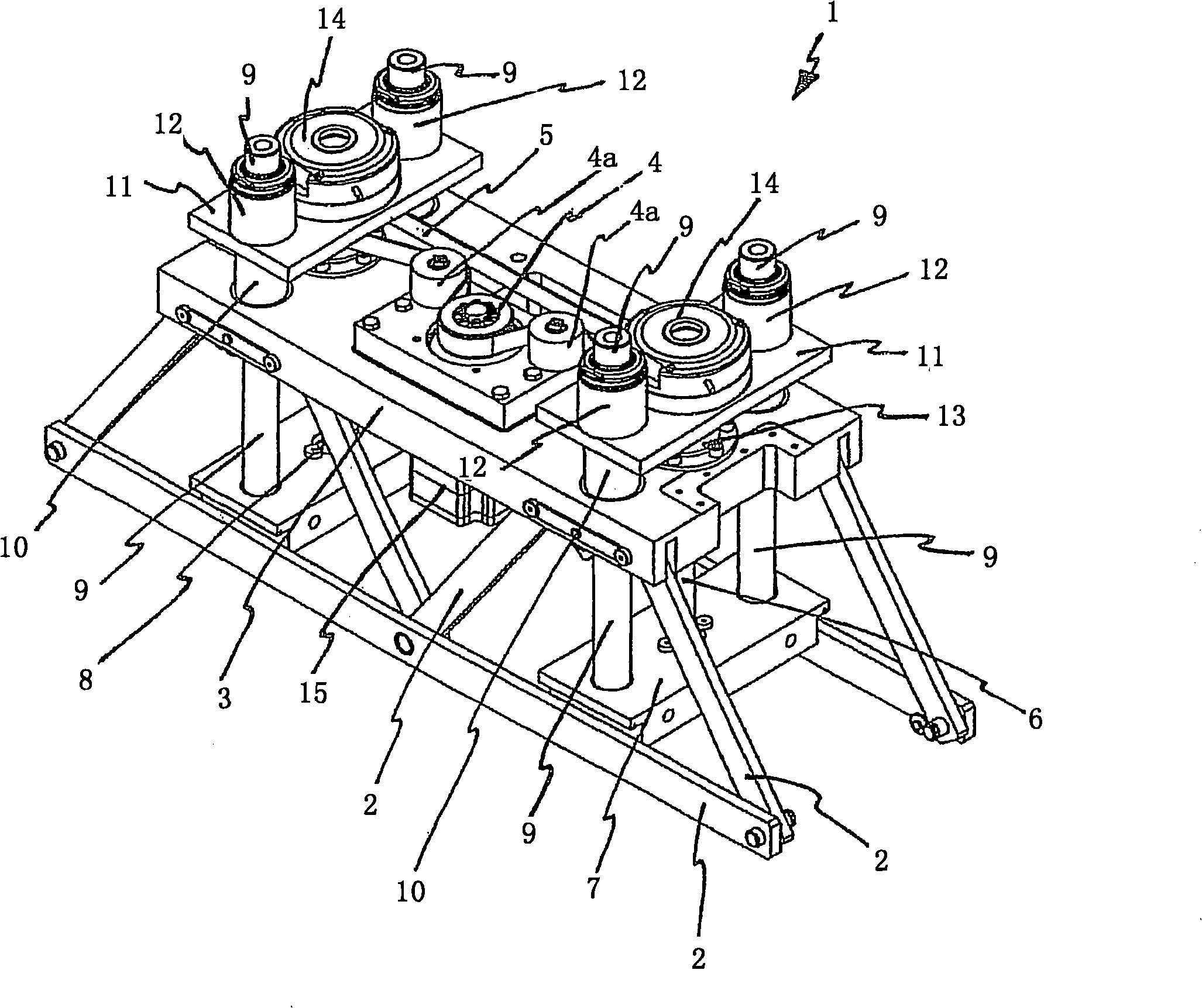

[0019] figure 2 The lifting mechanism 1 is shown in a schematic perspective view. The carrying plate 3 together with the bracket 2 forms the trapezoidal basic subassembly of the lifting mechanism 1 when viewed from the side. On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com