Composite floor board with bevel edge and manufacture technology thereof

A composite floor and production process technology, applied in the direction of manufacturing tools, wood processing appliances, floors, etc., can solve the problems of uneven substrate material, easy falling off, uneven pressure, etc., to achieve good overall effect, simple process, improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

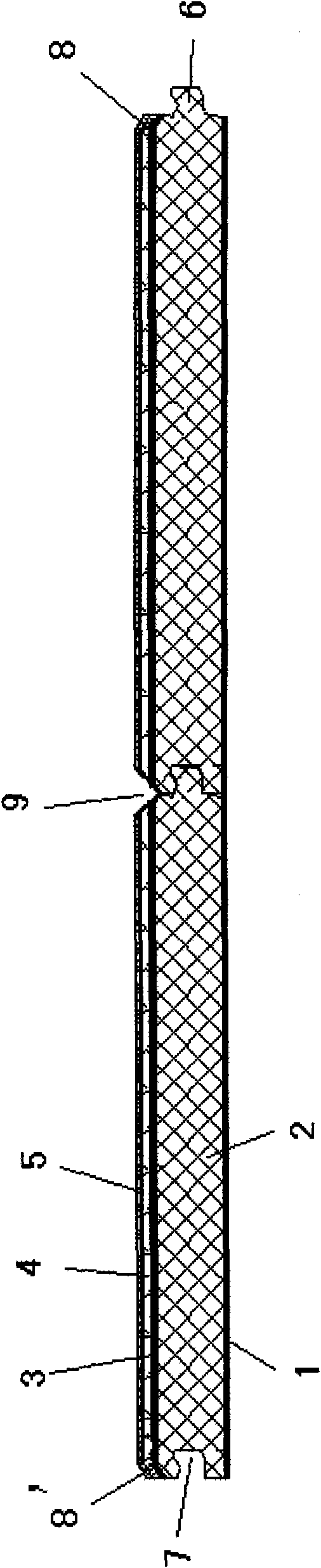

[0015] Such as figure 1 As shown, the floor of the present invention is formed by bonding 4 to 5 layers of materials, and these layers of materials are balance paper 1, floor substrate 2, face paper 3, wear-resistant layer 4, and paint layer 5. Wherein the balance paper 1 is the bottom layer, pasted on the back side of the floor substrate 2, can keep the force balance on the upper and lower sides of the floor substrate 2, and prevent the deformation of the floor substrate 2. A face paper 3 is pasted on the upper surface of the floor substrate 2 , and a wear-resistant layer 4 is pasted on the face paper 3 , and a paint layer 5 is coated on the wear-resistant layer 4 . The paint layer of the floor of the present invention is not necessary, depending on actual needs, coating the paint layer 5 can increase wear resistance and brightness, and the remainin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com