Combined structure of panhandle and pan body

A pot body and pot handle technology, which is applied in the combined structure of pot handle and pot body, can solve the problems of complex design, large space occupation, troublesome loading and unloading, etc., and achieve the effect of simple use and convenient assembly of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

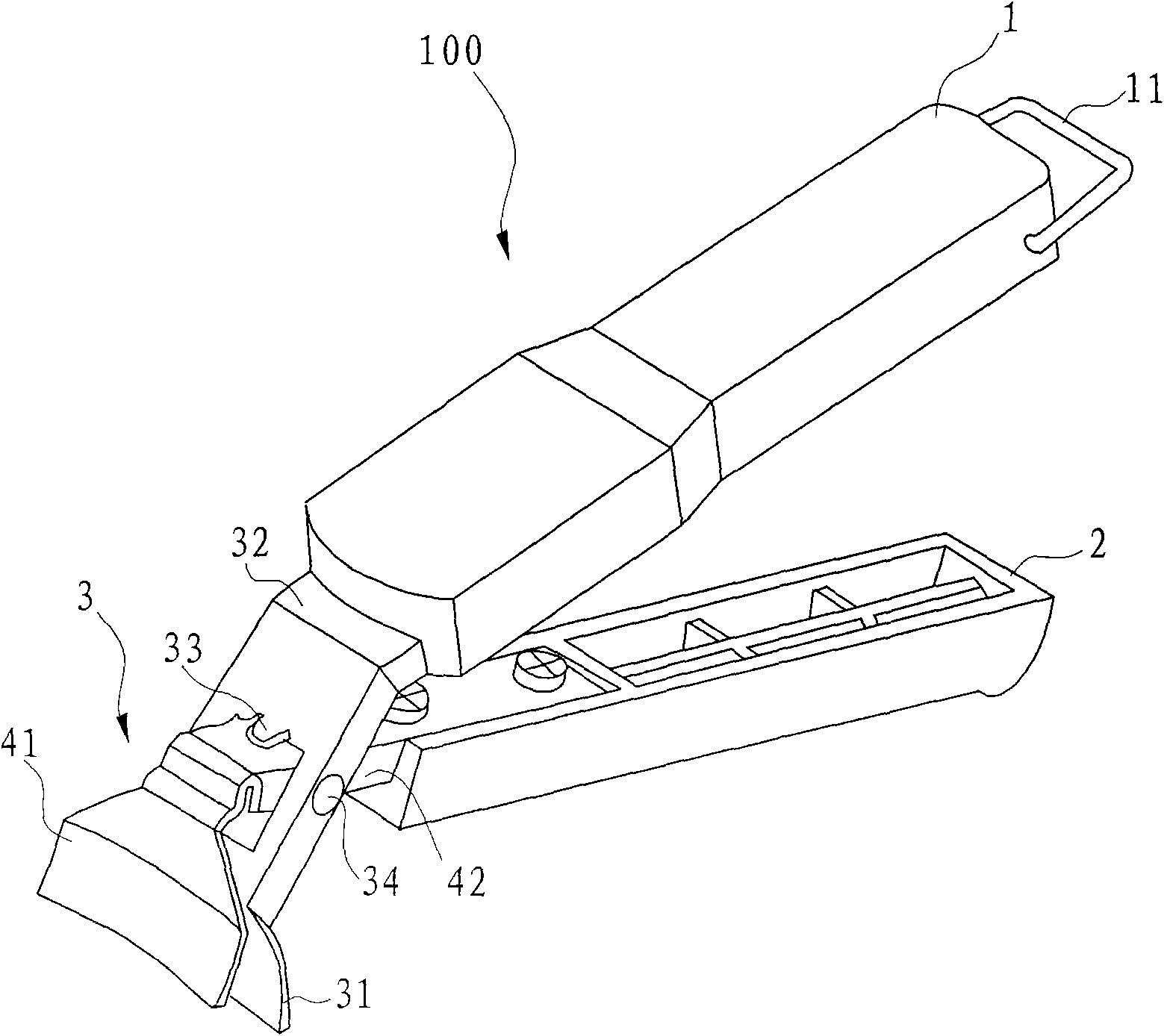

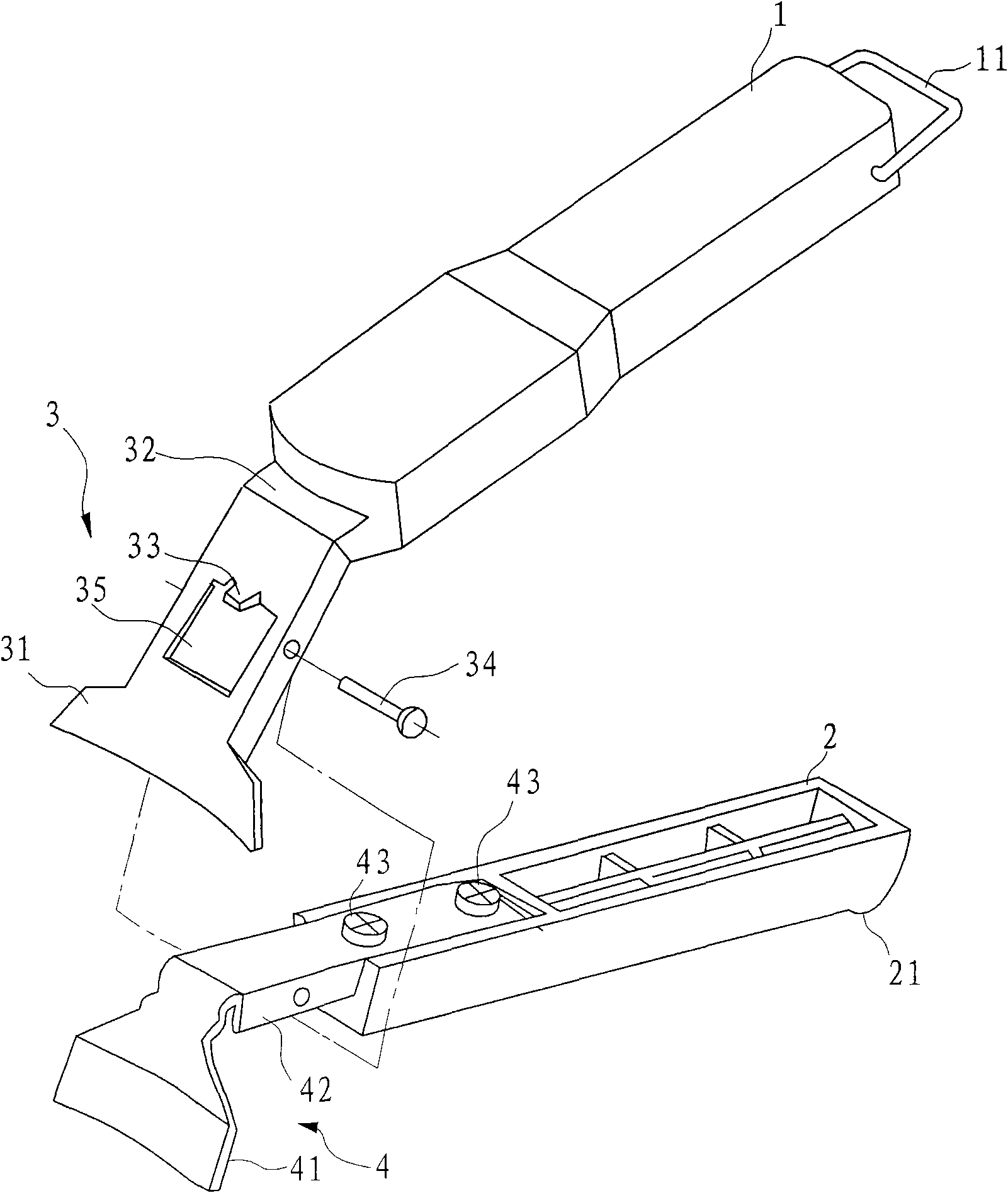

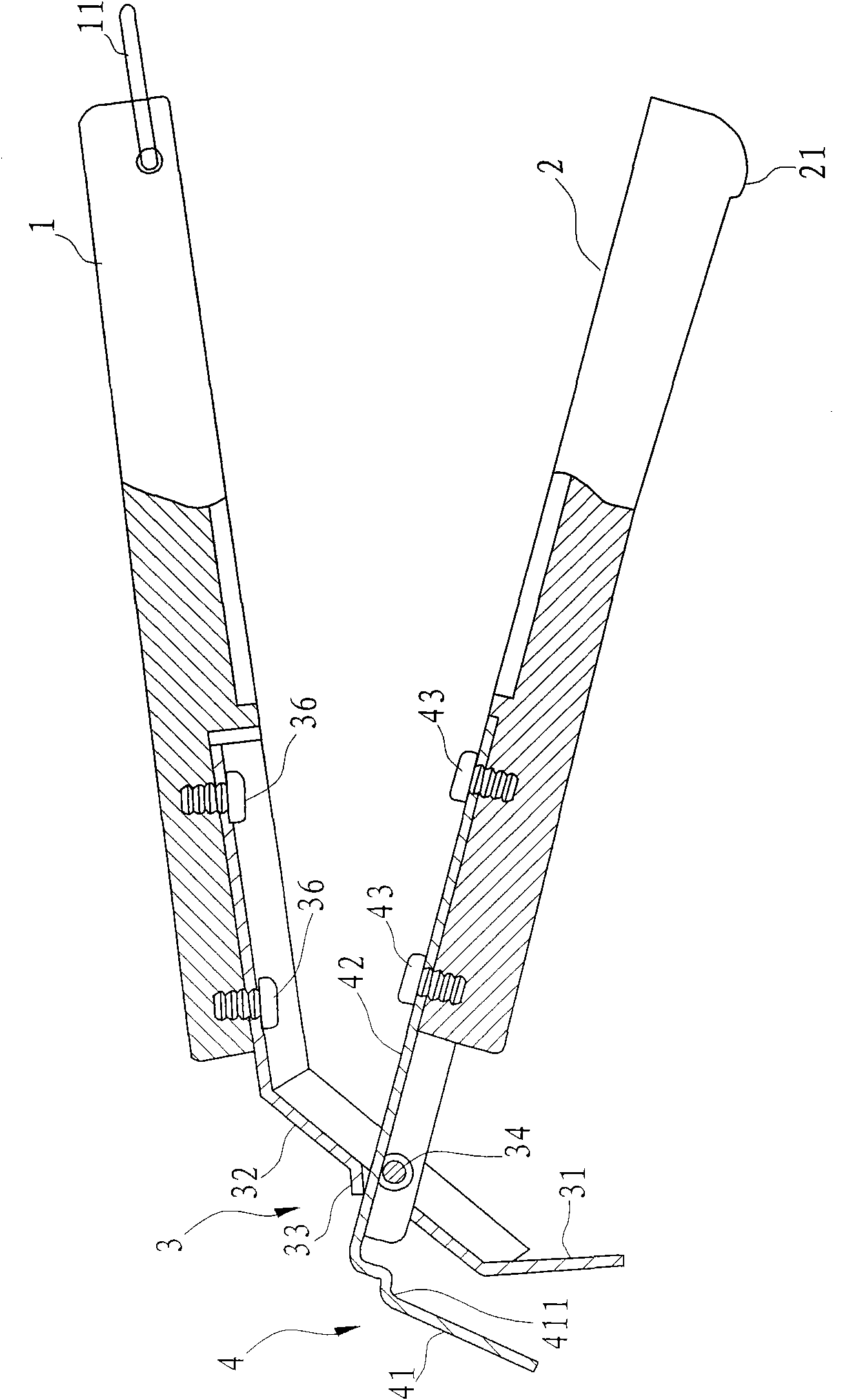

[0030] Example: such as Figure 1 to Figure 4 As shown, this embodiment includes a pot body 101 and a pot handle 100 , and the pot handle 100 includes an upper handle 1 and a lower handle 2 .

[0031] The front end of the upper handle 1 is provided with a first splint 3 , and the rear end is provided with a clasp 11 , the clasp 11 is rotatable relative to the upper handle 1 , and the middle of the first splint 3 has a through hole 35 .

[0032] The front end of the lower handle 2 is provided with a second splint 4 that can clamp the side of the pot body 101 in cooperation with the first splint 3, and the rear end has a snap ring 11 for fastening and matching to make the upper handle 1 and the lower handle 2 combined with a limit flange 21, the rear end of the second splint 4 passes through the through hole 35 on the first splint 3 and is provided on the lower handle 2, the second splint 4 and the first splint 3 The middle parts can realize mutual rotation through a pin shaft ...

Embodiment 2

[0036] Embodiment 2: as Figure 5 and Figure 6 As shown, the clamping part of the pot body 101 in this embodiment has internal tooth lines 4b and external tooth lines 3b, and correspondingly, the inner wall of the second clip part 41 has a second tooth line that clamps and cooperates with the internal tooth lines 4b 4a, the inner wall of the first clip part 31 has the first tooth pattern 3a clampingly matched with the external tooth pattern 3b. The grip becomes stronger. Other structures are the same as the embodiment.

Embodiment 3

[0037] Embodiment 3: as Figure 7 As shown, the inner wall of the second clip part 41 in this embodiment has a non-metal soft second gasket 4c, and the inner wall of the first clip part 31 has a non-metal soft first gasket 3c. The setting of the second gasket 4c and the first gasket 3c can increase the frictional force of the first clip part 31 and the second clip part 41 to the pot body 101, and the clamping is more firm. The second gasket 4c and the first The gasket 3c has poor thermal conductivity, which reduces the heat transfer to the pot handle 100, which is beneficial for the user to hold it for a long time without burning sensation. The material selection of the second gasket 4c and the first gasket 3c should meet the requirements of safety, non-toxicity, and high temperature resistance. In addition, other structures are the same as those in the embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com