Hybrid power-driven system

A driving system and hybrid power technology, applied in the direction of engine-driven traction, power device, electric power device, etc., can solve the problems of increasing the power sharing of the planetary gear mechanism, high implementation cost, complex structure, etc., and achieve industrialization , easy to implement, and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

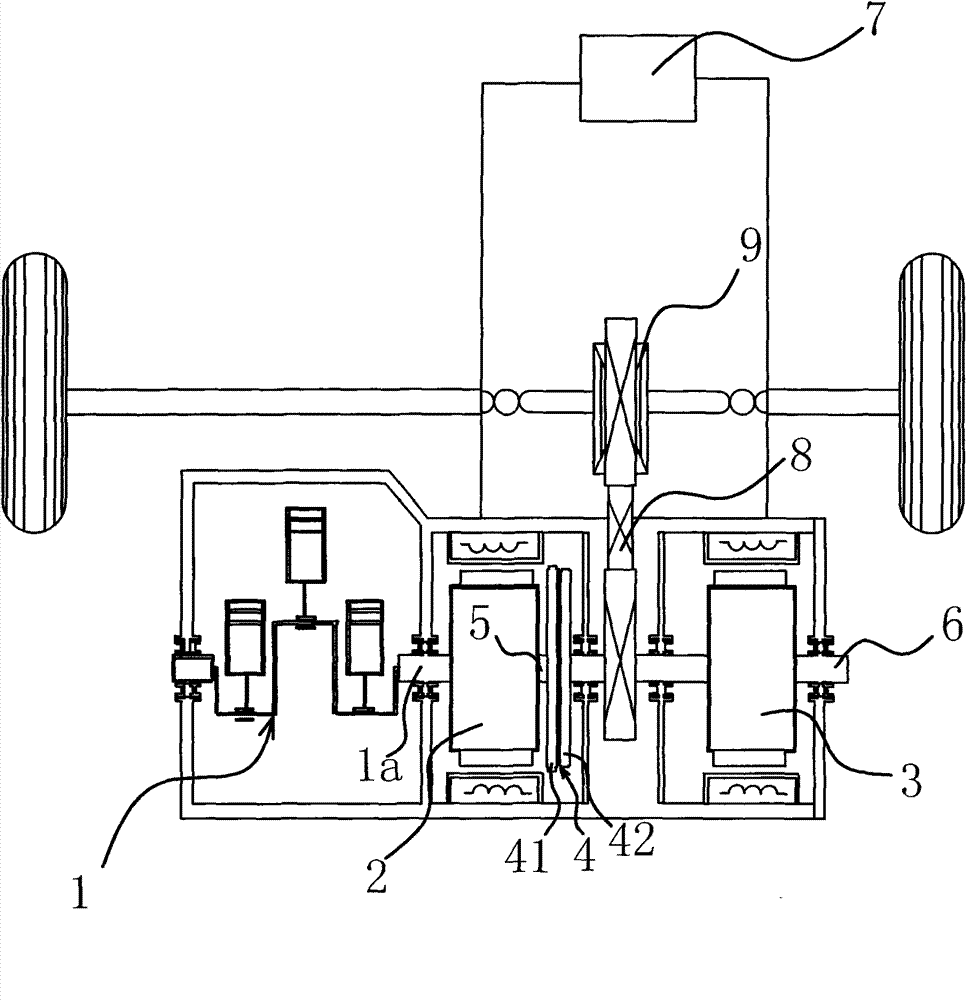

[0019] Such as figure 1 As shown, the hybrid drive system includes an engine 1 and the same first motor 2 and second motor 3, the first motor shaft 5 of the first motor 2, the second motor shaft 6 of the second motor 3 and the output shaft 1a of the engine 1 The three shafts are concentric, and the output shaft 1a is fixedly connected with the motor shaft one 5. A normally open clutch 4 is arranged between the first motor shaft 5 and the second motor shaft 6, the combination and disconnection of the controllable motor shaft one 5 and the second motor shaft 6, the first motor 2 and the second motor 3 are electrically connected with Battery 7. The clutch 4 includes a driving part 41 and a driven part 42 oppositely arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com