Wafer acceptance testing method, contact mat and probe card

A technology of wafer acceptance testing and contact pads, which is applied in the direction of electronic circuit testing, single semiconductor device testing, electrical measurement, etc., can solve the problem that the utilization rate of the wafer surface area cannot be improved, and achieve the effect of reducing the width and increasing the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to illustrate the structure and features of the present invention in detail, the following preferred embodiments are given and described with reference to the drawings.

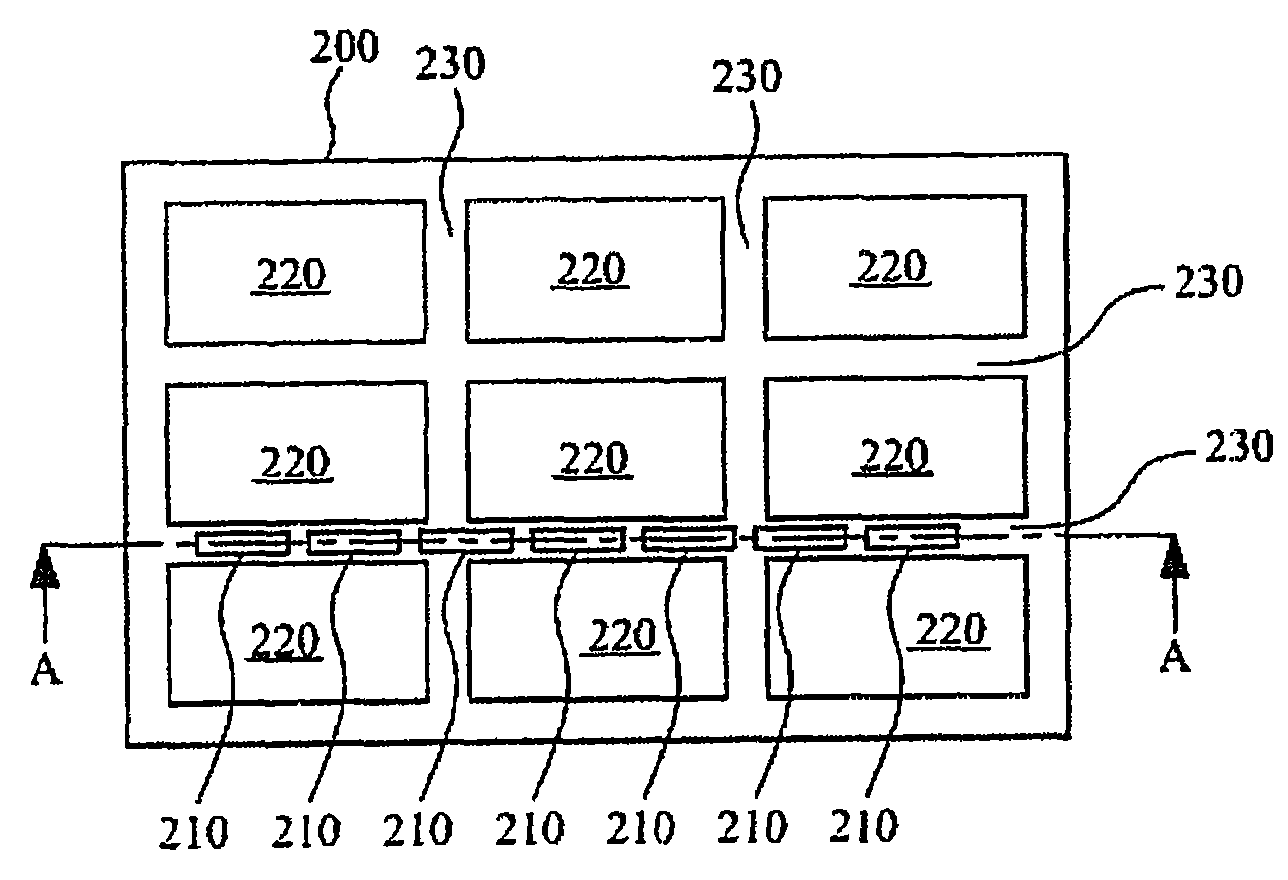

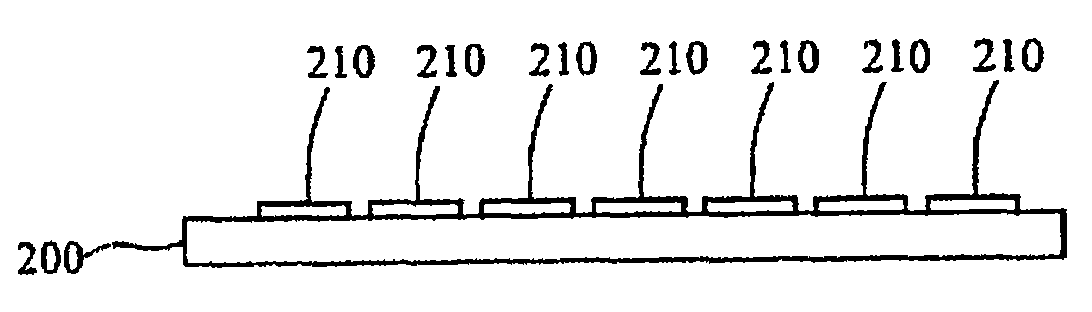

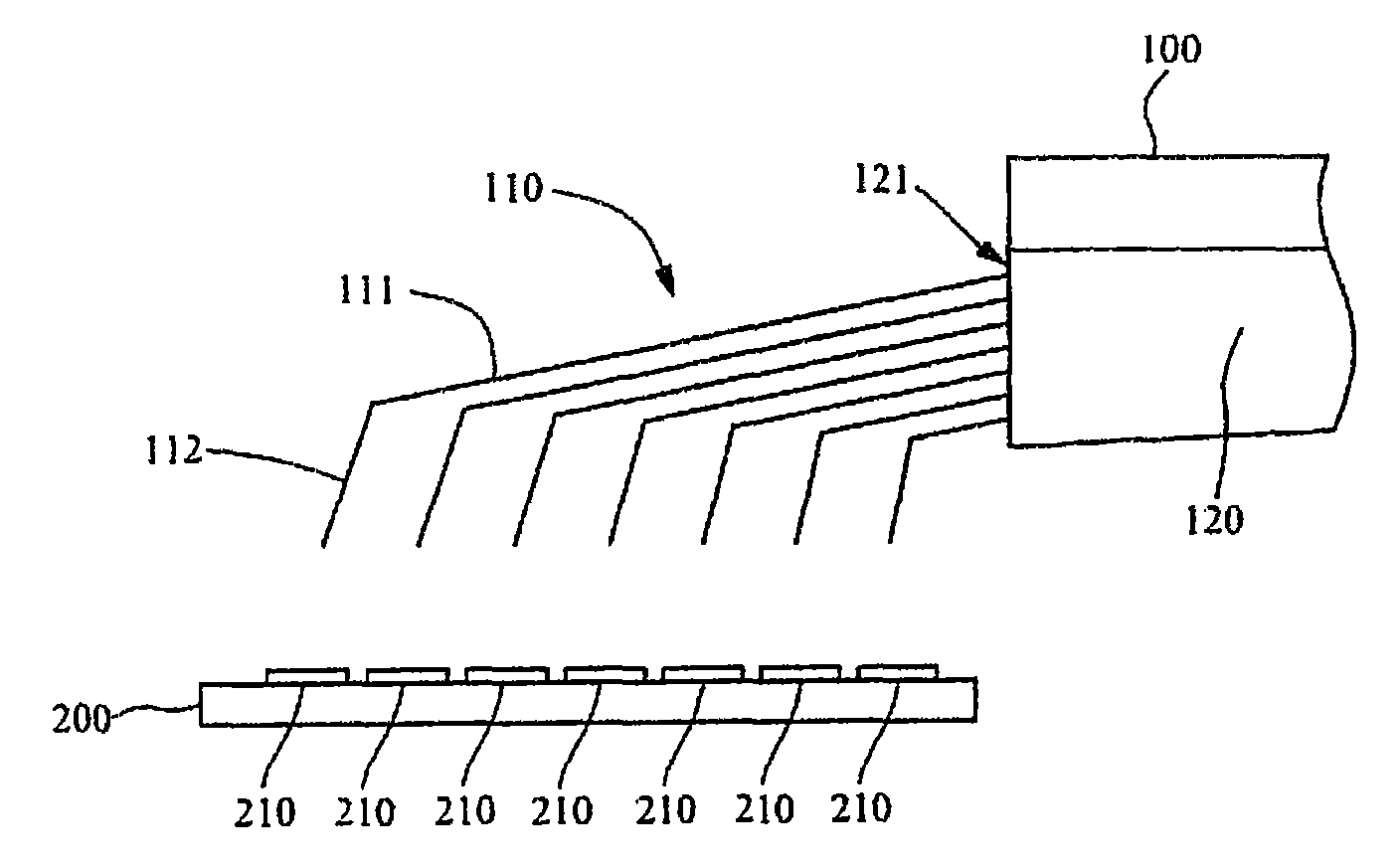

[0045] see figure 1 , 2 , 3 and 4, it is a wafer acceptance test method disclosed by the embodiment of the present invention, which is through the relative contact between the cantilever probe 110 of the probe card 100 and the contact pad 210 of the wafer 200. Position configuration, so that each cantilever probe 110 can definitely contact its corresponding contact pad 210 with an appropriate contact pressure, and the needle tip will not move out of the contact pad 110 due to the compression deformation of the cantilever probe 110 .

[0046] The wafer 200 used in the present invention forms a plurality of electronic components arranged in an array on the surface of the wafer 200 after the semiconductor component process. The multiple electronic components need to be further tested to determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com