Method for removing residual photoresist

A technology of photoresist and photoresist layer, applied in photosensitive material processing, electrical components, semiconductor/solid-state device manufacturing, etc., can solve photoresist residue, affect the uniformity of the second ion implantation and the second doping area, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In this embodiment, plasma treatment is used to remove the photoresist residue left in the doped area to prevent the photoresist residue from affecting the subsequent processing of the second doped area.

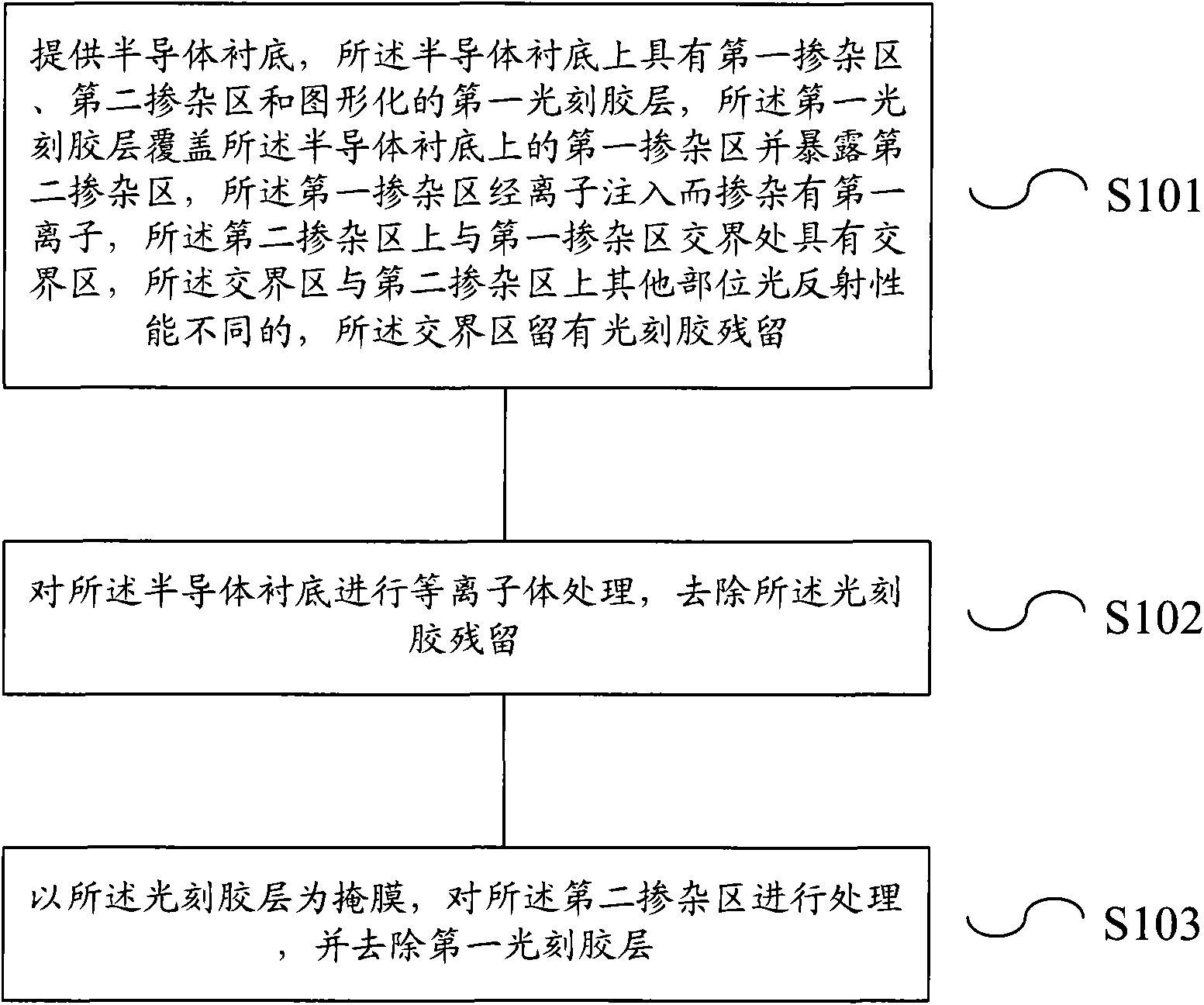

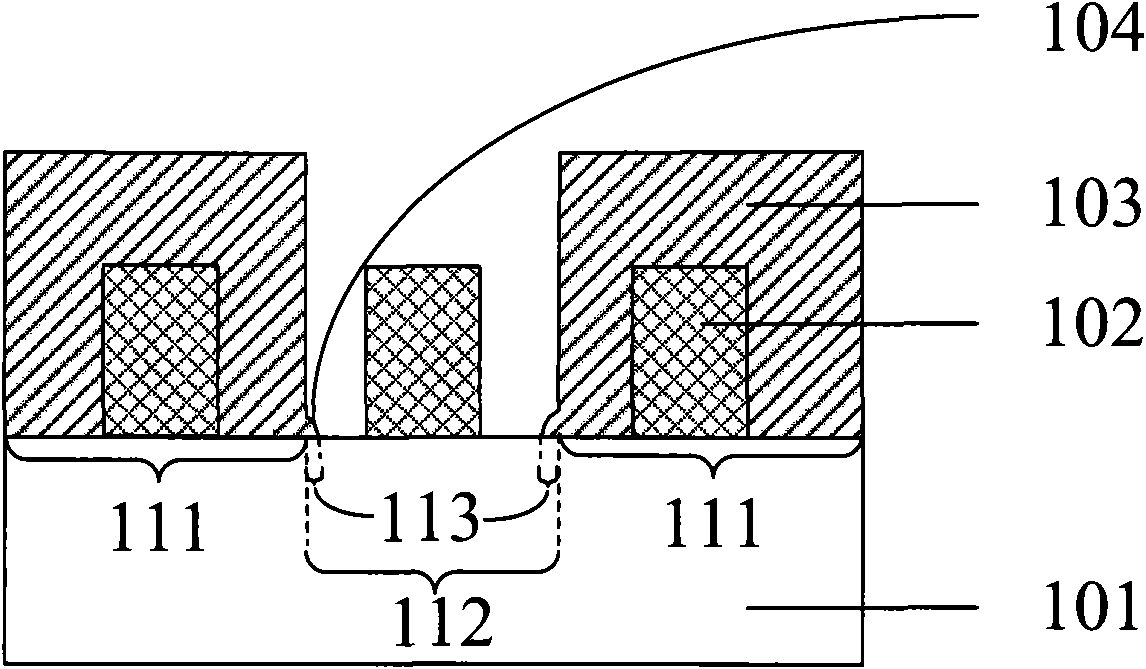

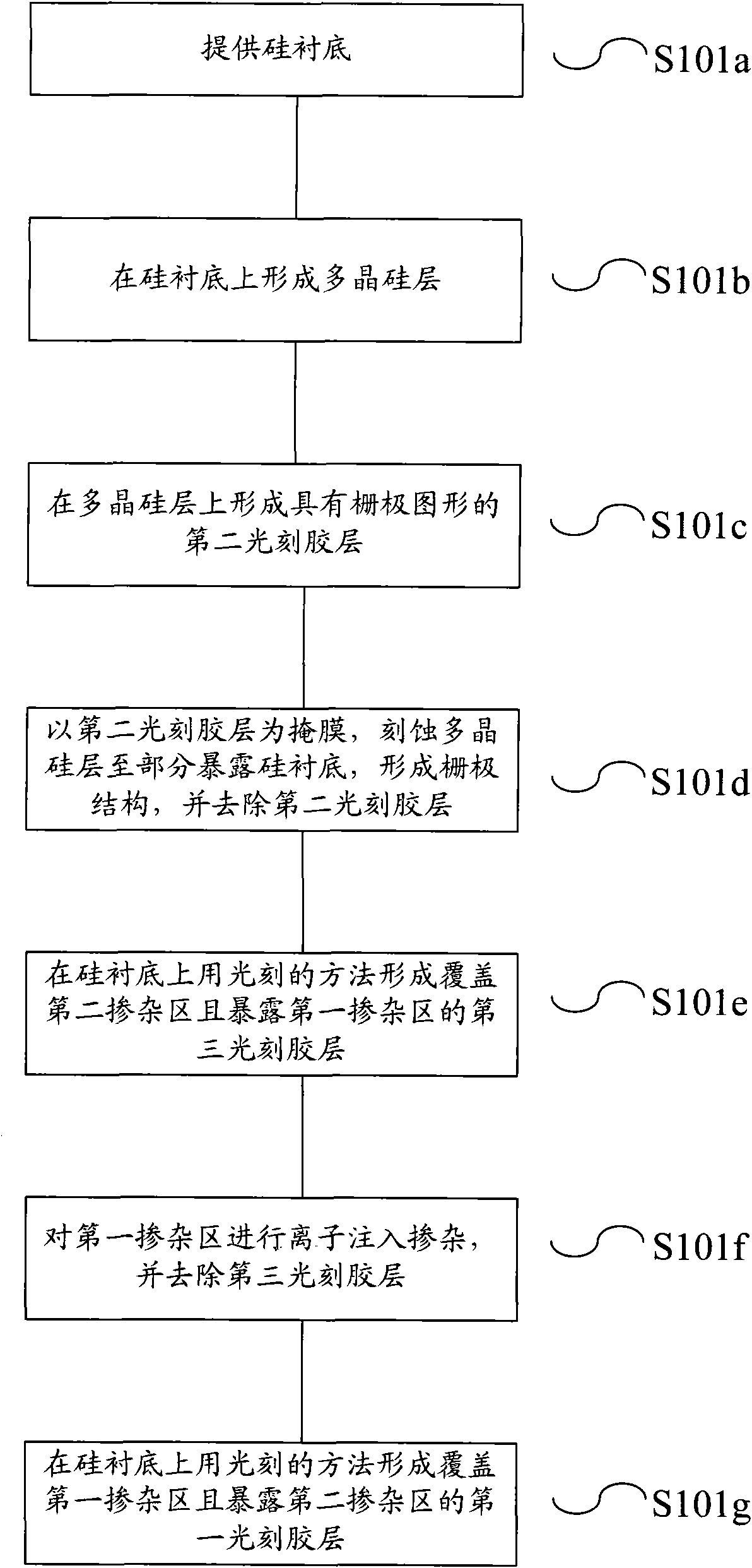

[0018] To this end, this embodiment provides a method for removing photoresist residues, which includes the steps of: providing a semiconductor substrate having a first doped region, a second doped region, and a patterned photoresist on the semiconductor substrate. Layer, the photoresist layer covers the first doped region on the semiconductor substrate and exposes the second doped region, the first doped region is doped with first ions by ion implantation, the first There is a boundary area at the boundary between the second doped area and the first doped area. If the light reflection performance of the boundary area is different from other parts of the second doped area, the boundary area is left with photoresist residue; Plasma treatment is performed on the semiconduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com